Box Tape by Hand?

Discover Our Case Sealer Machine

What's Your Case?

An Industrial Case Sealer Machine Provides Consistent, Reliable Packaging to Meet Production Needs and Keep Products Secure

We offer a range of semi and automatic case sealing machines designed to be heavy-duty solutions for your case sealing applications. Sealing material types include tape and hot-melt adhesives to provide maximum seal integrity.

Current innovative marketing creates a demand for different product packaging requirements where versatility and efficiency are at a premium. To meet those challenges, we offer several models including: Sanitary Washdown, Top & Bottom Sealing, Random Case Sealing, Random Height Case Sealing, Low-Profile Clamshell, Pizza Box, and Die-Cut Folder Types.

Whether you have semi-automatic or fully automatic case sealer machine needs, speeds up to 40 cases per minute, we can provide a budget friendly solution that will increase production line performance and efficiency.

Automatic Case Sealer Machine

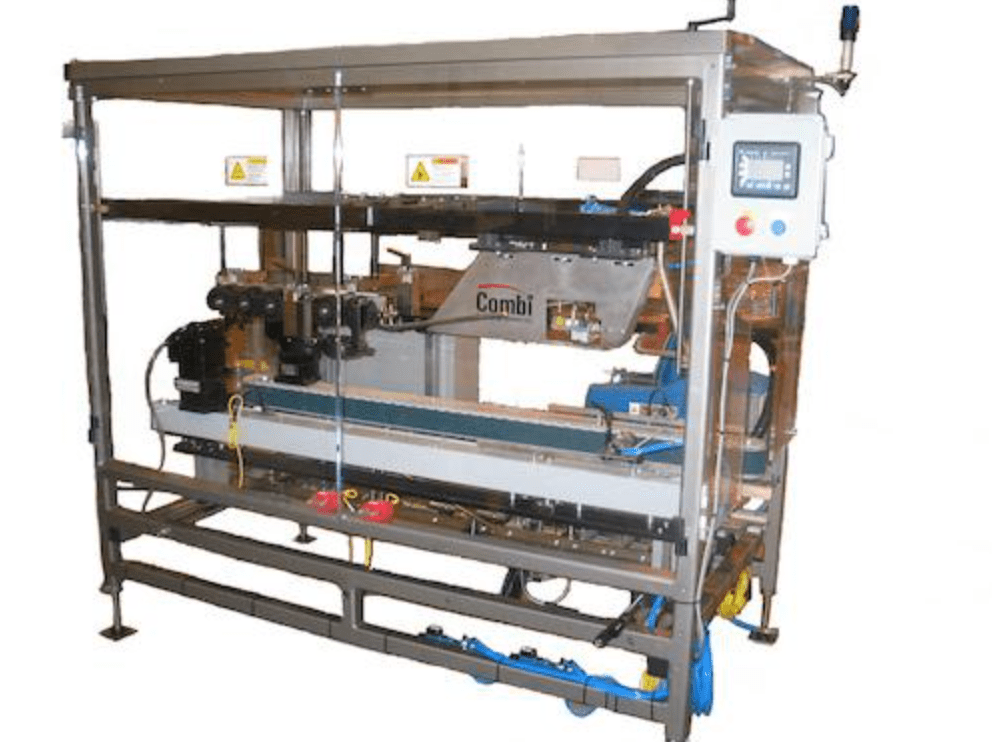

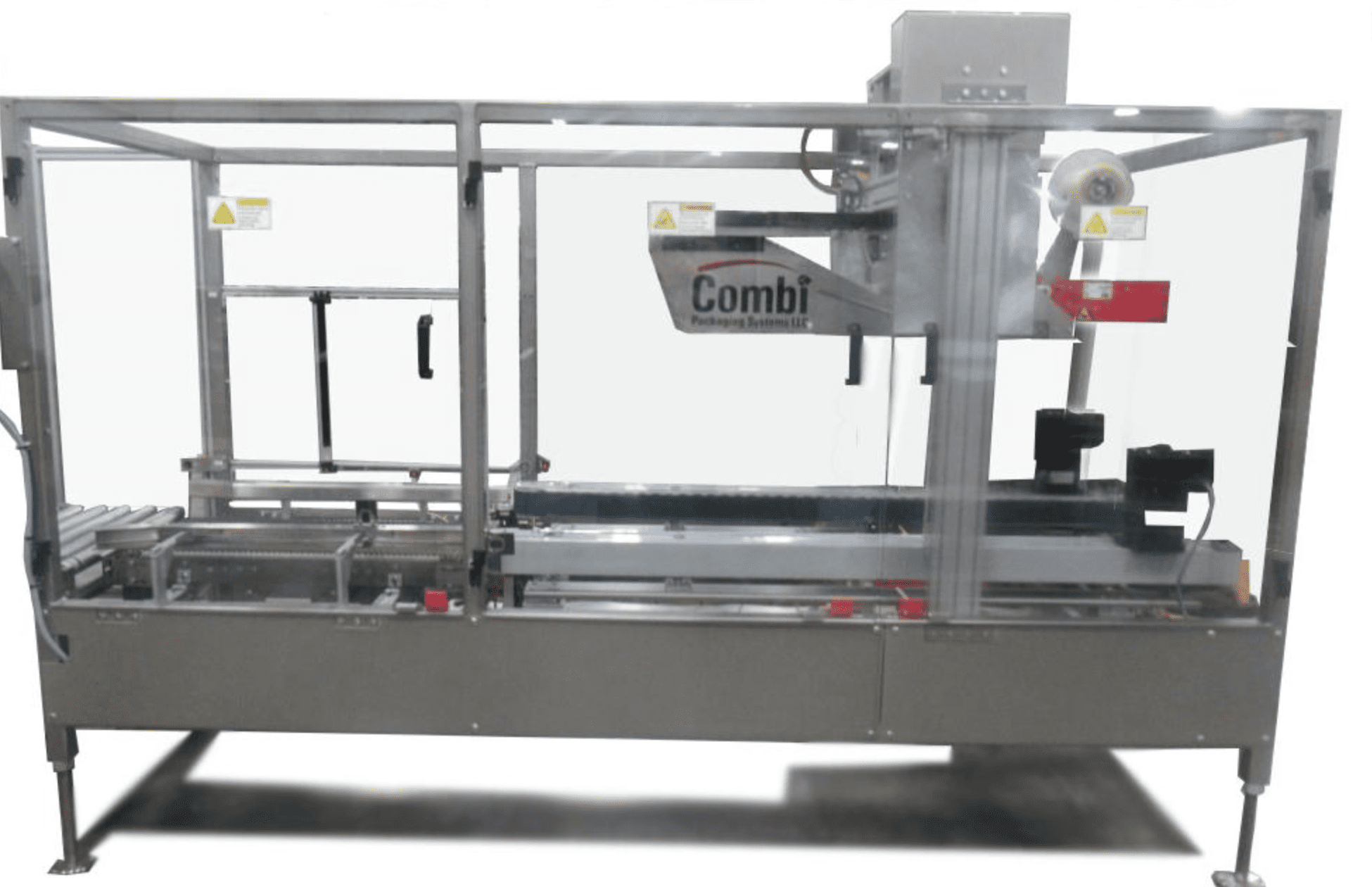

Combi Packaging Case Sealer

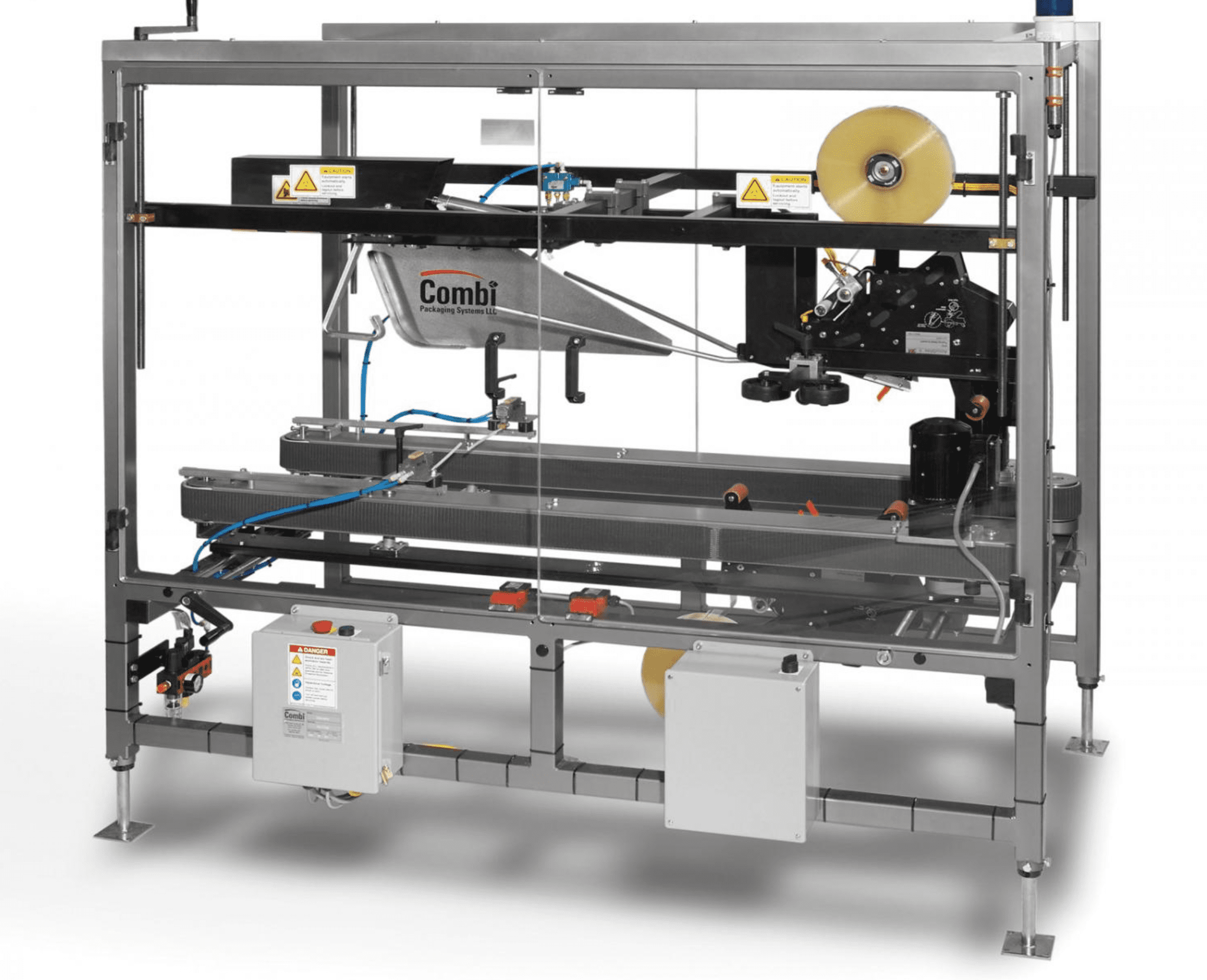

Combi Packaging Top & Bottom Automatic Case Sealer Machine

TBS MODELS

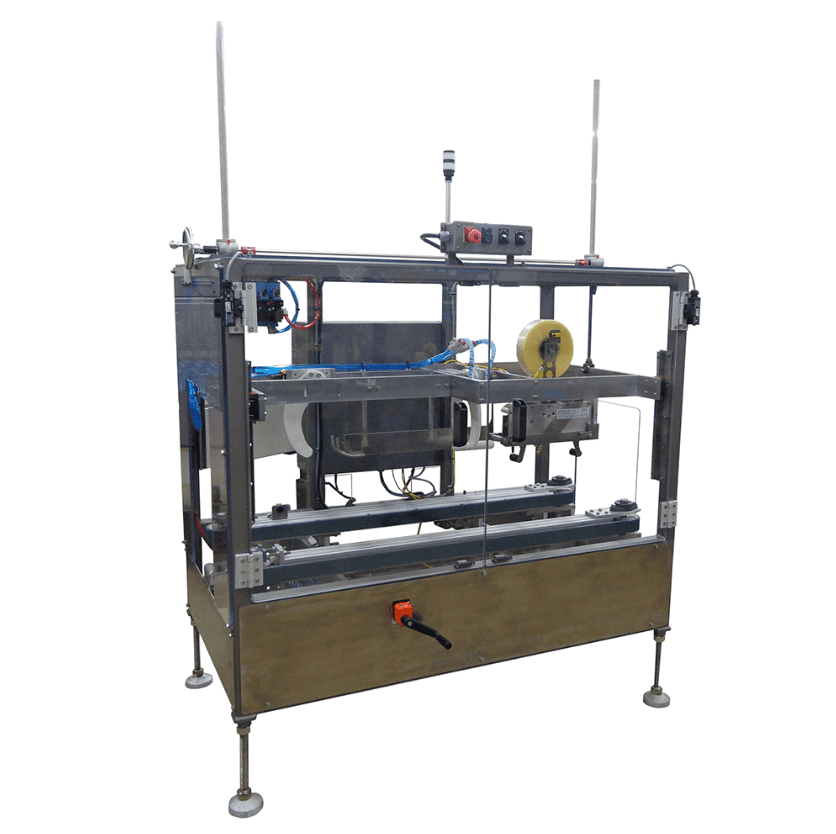

L-Clip Case Sealer-TBS Series is designed to close low profile clamshell, pizza box, and die cut folder type boxes with our TBS L-Clip case sealer machine. The fully automatic case sealers apply a 2″, 3″ or 6″ strip of adhesive tape to the leading or wide side bottom edge of cartons. The L-Clip case sealer features laminated V-Drive belts with self-tensioners and no-tool crank adjustments.

TBS-100 Heavy Duty Case Sealer is a heavy-duty solution for a wide range of case sealing applications. This machine features extra heavy-duty construction, oversized motors and drive components. The TBS-100 is a modular system that is adaptable to top and/or bottom sealing and many flap folding configurations. This popular case sealer is available with tape or hot melt glue as options.

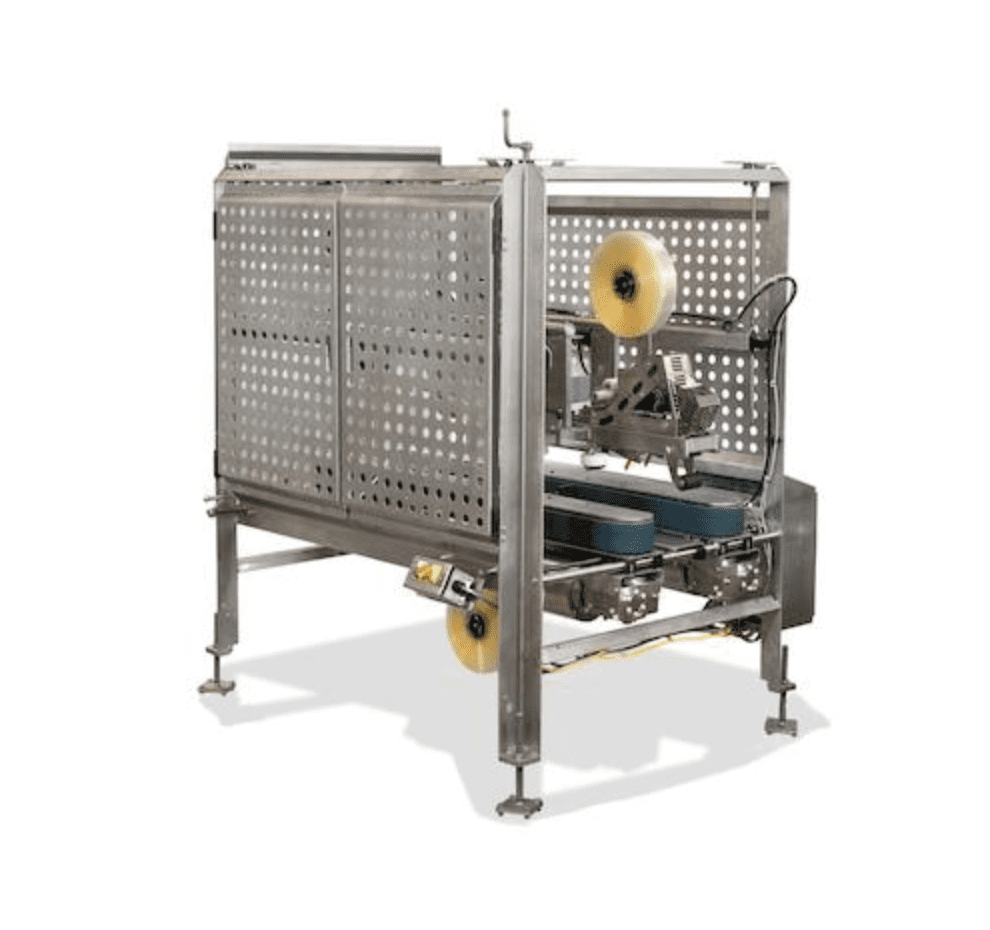

Sanitary Washdown Semi-Auto & Automatic TBS Case Sealer is designed of stainless steel, washdown semi-automatic and automatic sanitary design case sealers that virtually reduces and/or eliminates potential areas of undesirable bacteria.

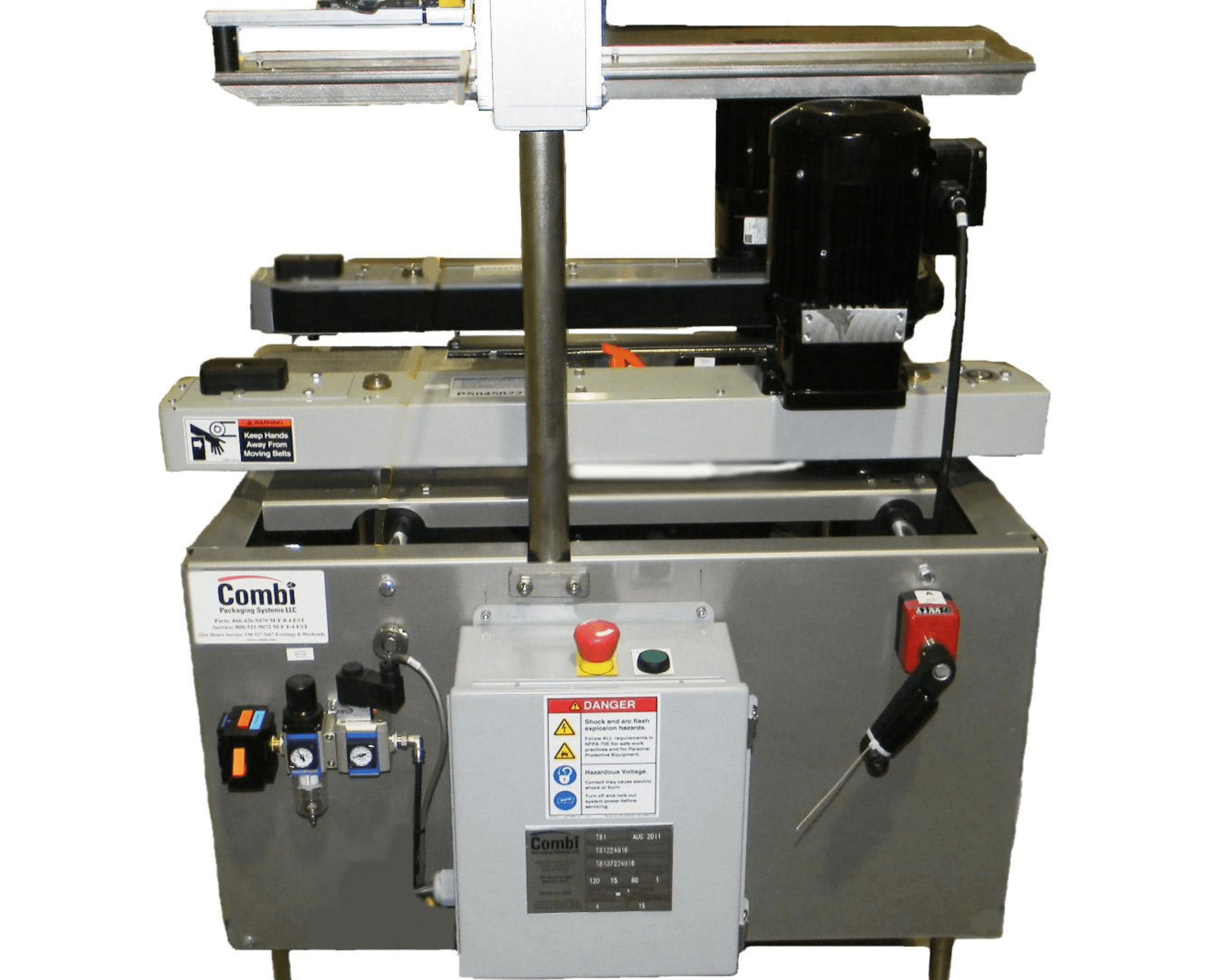

TBS-100SA H-Seal Case Sealer When you require added security to your filled corrugated cases or need to seal out food contaminants, Combi offers a semi-automatic case sealer with an H seal that securely seals both the top and bottom of your case with adhesive tape. 3M Accuglide tape heads efficiently seal the top and bottom of RSC and HSC cases.

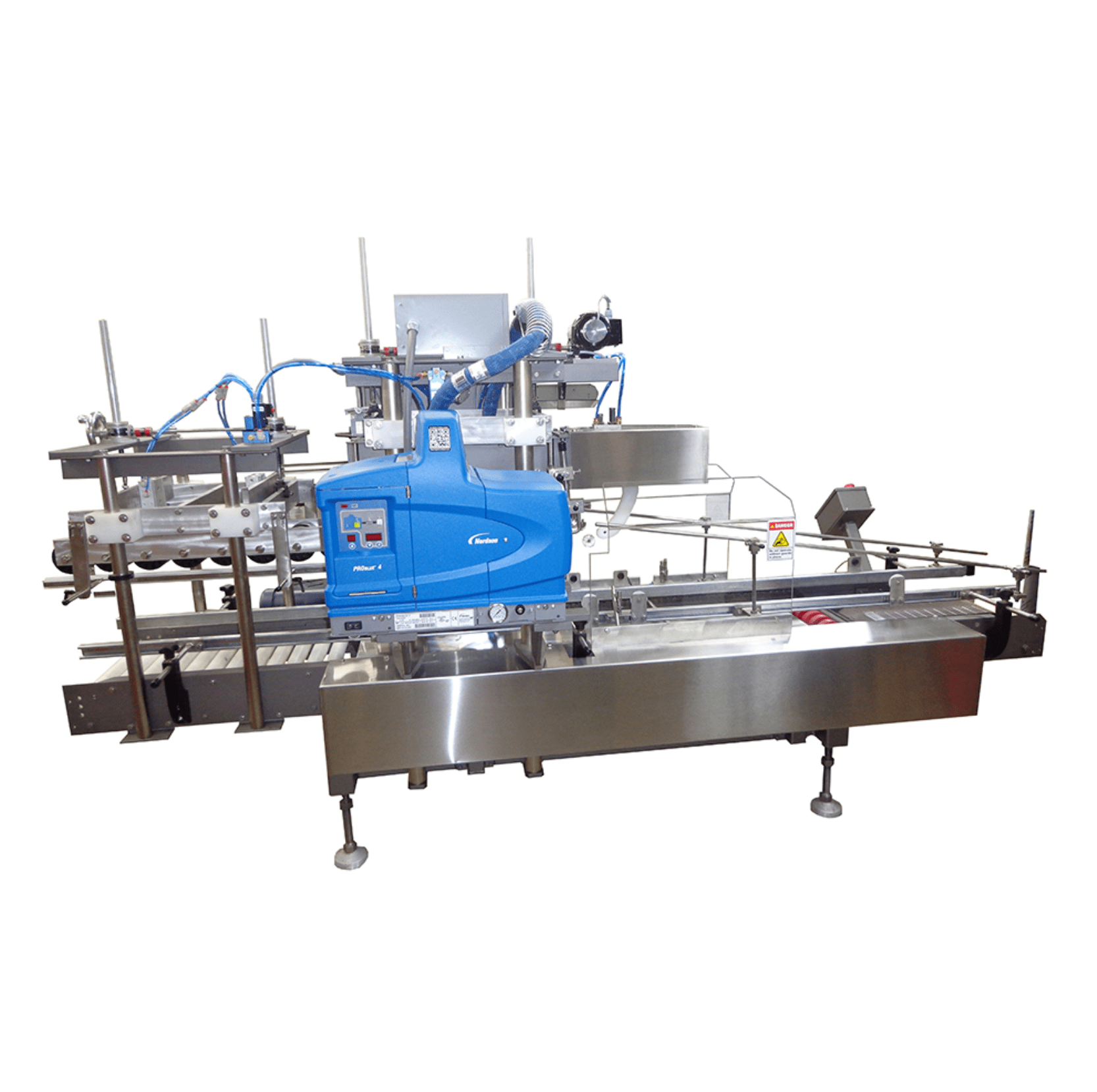

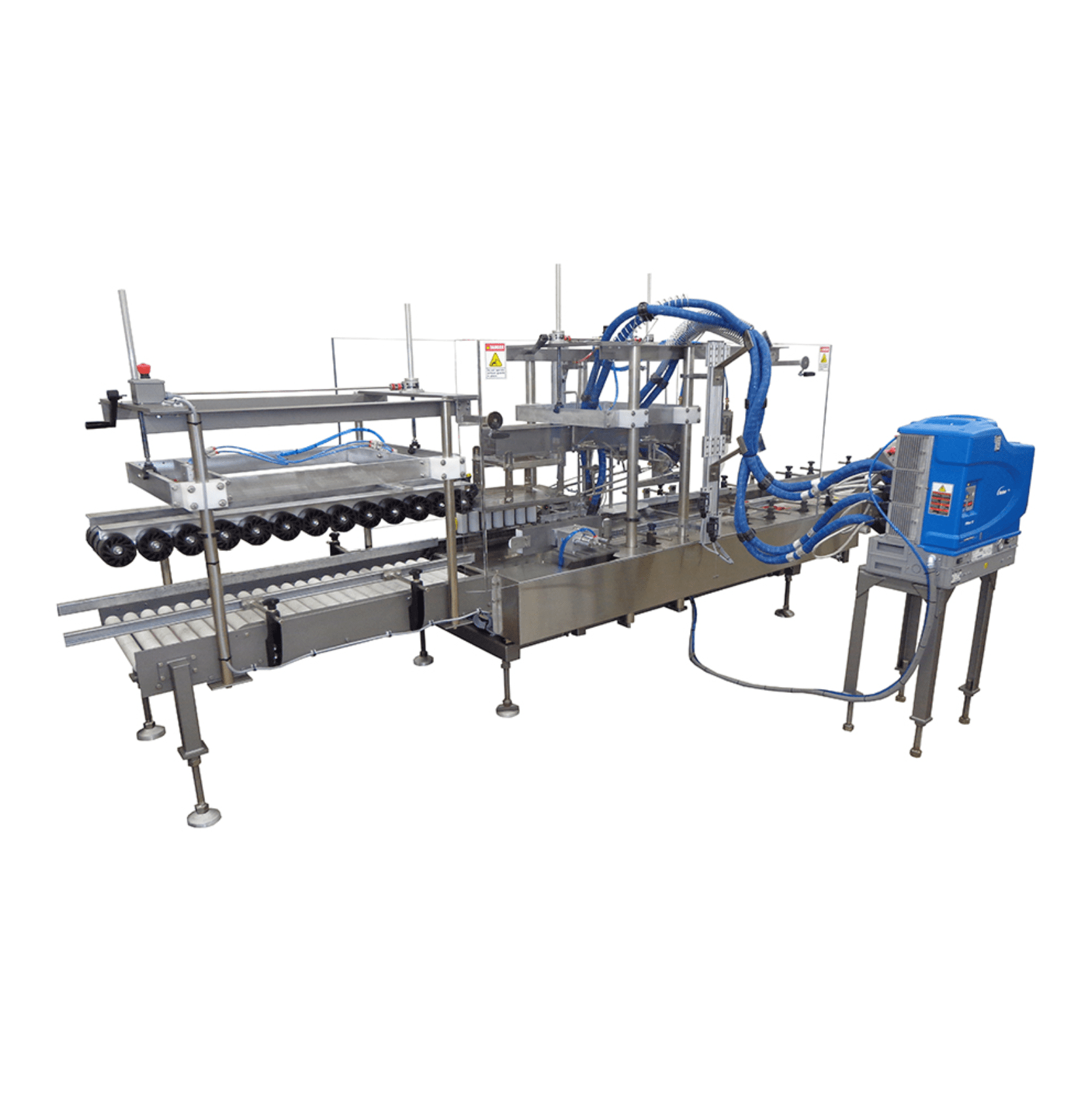

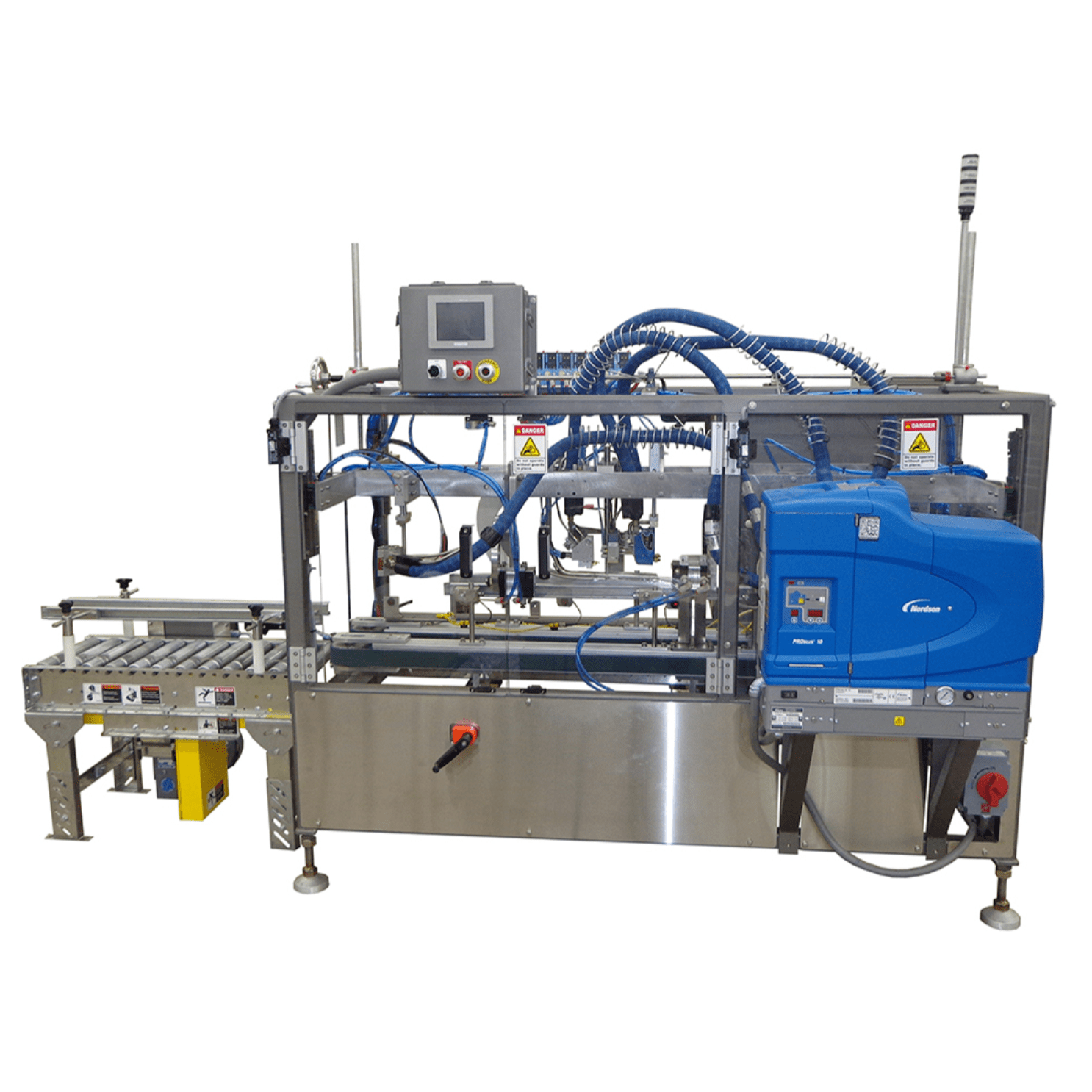

Hot Melt Glue Case Sealer If your cases need a stronger bond than adhesive tape can provide, the TBS Hot Melt glue case sealers can provide the maximum seal integrity to ensure a secure case. TBS hot melt case sealing machines are available in lug drive, belt drive configurations and are equipped with Nordson ProBlue Liberty™ integrated tankless hotmelt glue systems.

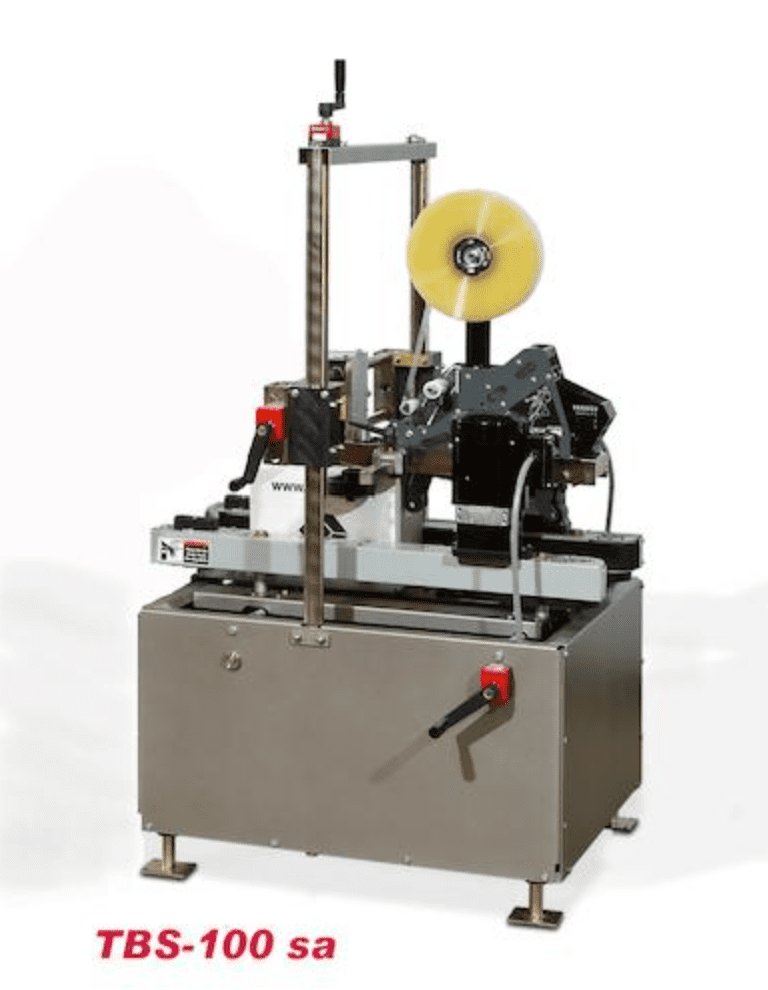

TBS-100 SA Semi-Automatic Case Sealer is a standalone, semi-automatic case sealing system and is built with the same heavy-duty tubular steel frame as other Combi equipment. 3M™ Accuglide tape head(s) efficiently seals top and/or bottom and the modest footprint of the case sealer takes up little floor space. Tape roll changes are easy, changeovers simple and repeatable.

TBS-100R Random Case Sealer is a reliable random case sealing solution for different size cases. Have several packaging lines and limited floor space for sealers? Combi’s TBS-100R can accept different size cases coming from different case packing lines and securely seal the top and bottom of the cases.

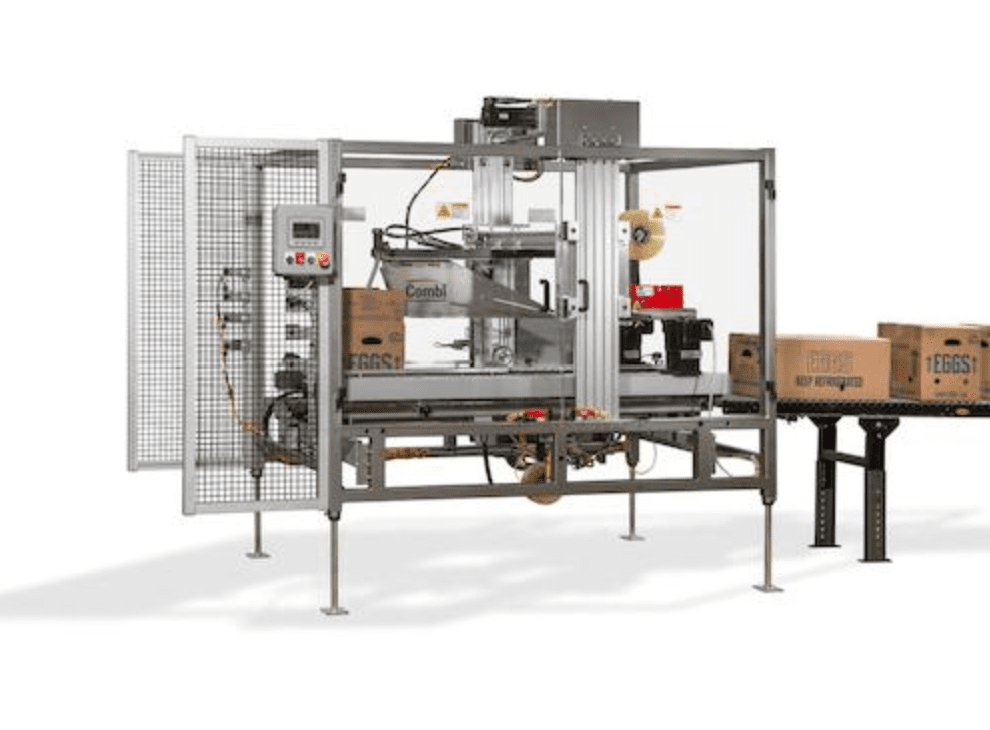

TBS-100RH Case Sealer is a reliable random case sealing solution and can seal four different heights of cases randomly. Multiple lines of packed cases can feed into this one packaging machine – cases can be of varying heights but similar case width. Ideal for egg producers in the food industry who fill RSC cases with cartons of eggs in varying pack counts. For safety, the random height case sealer is fully guarded with hinged doors and standard safety interlocks.

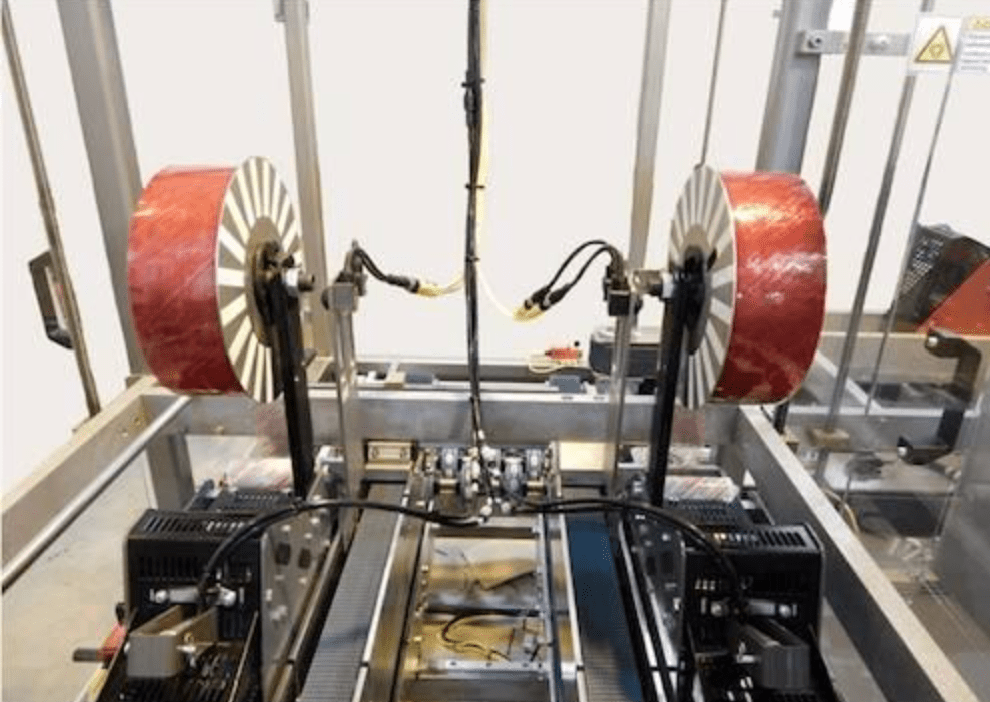

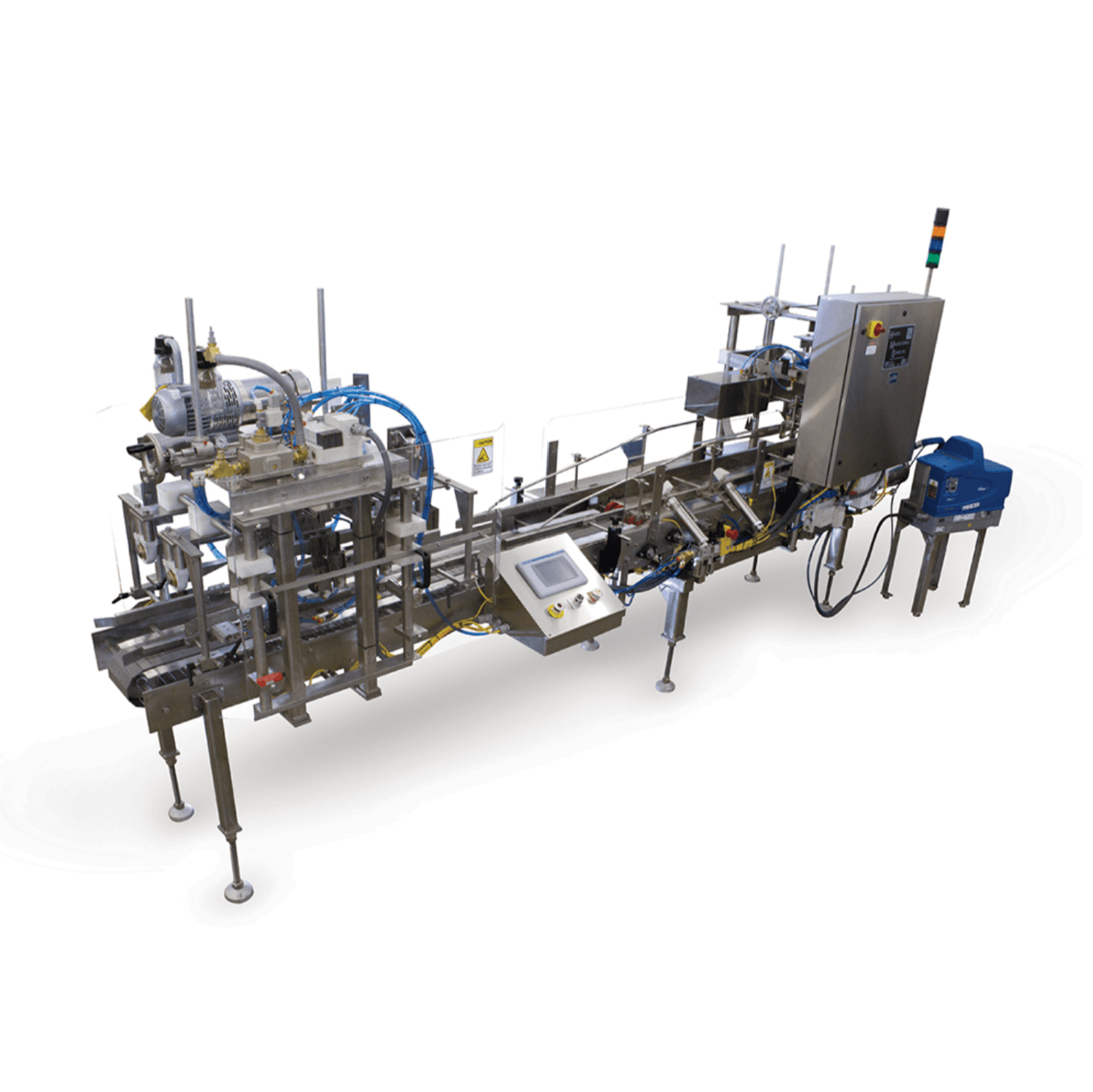

RS Series Random Case Sealers are built for speed and flexibility, our RS series random case sealers are ideal for high volume lines with varying case sizes in distribution or fulfillment centers or manufacturing sites where different lines converge for sealing.

We offer a choice of lug or side belt drives and two case size ranges. Side belt drives are ideal for varying sizes of tall and narrow cases. Each random case sealer is custom engineered to meet your specifications, including variations in case size, weight and operator orientation.

You can have a different size case at each stage of the sealing process at speeds up to 20 CPM with the Combi RS2000 or RS3000 Random Case Sealers.

Hamrick Packaging Case Sealers

Hamrick Packaging Systems Automatic Case Sealer Machine

MODELS

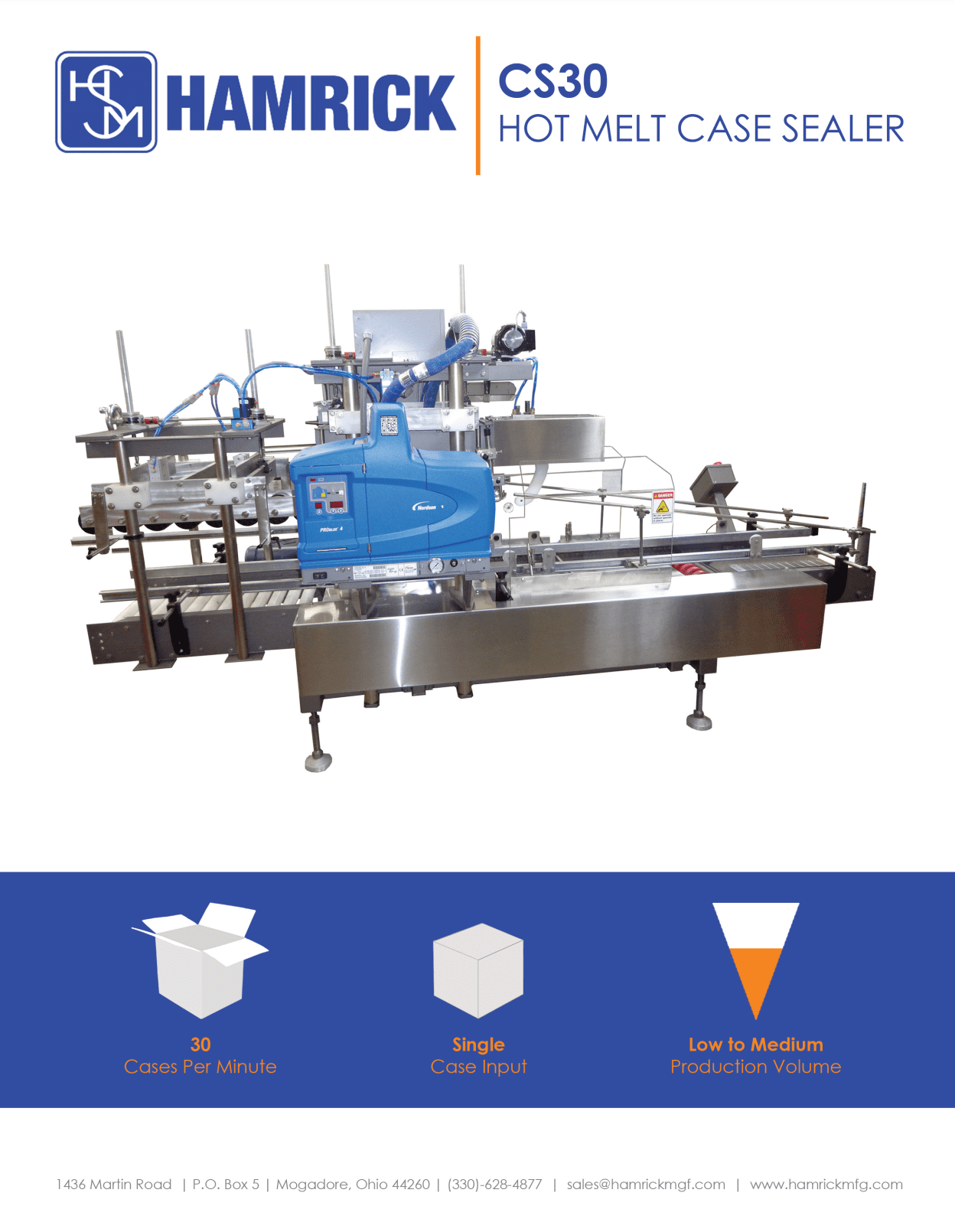

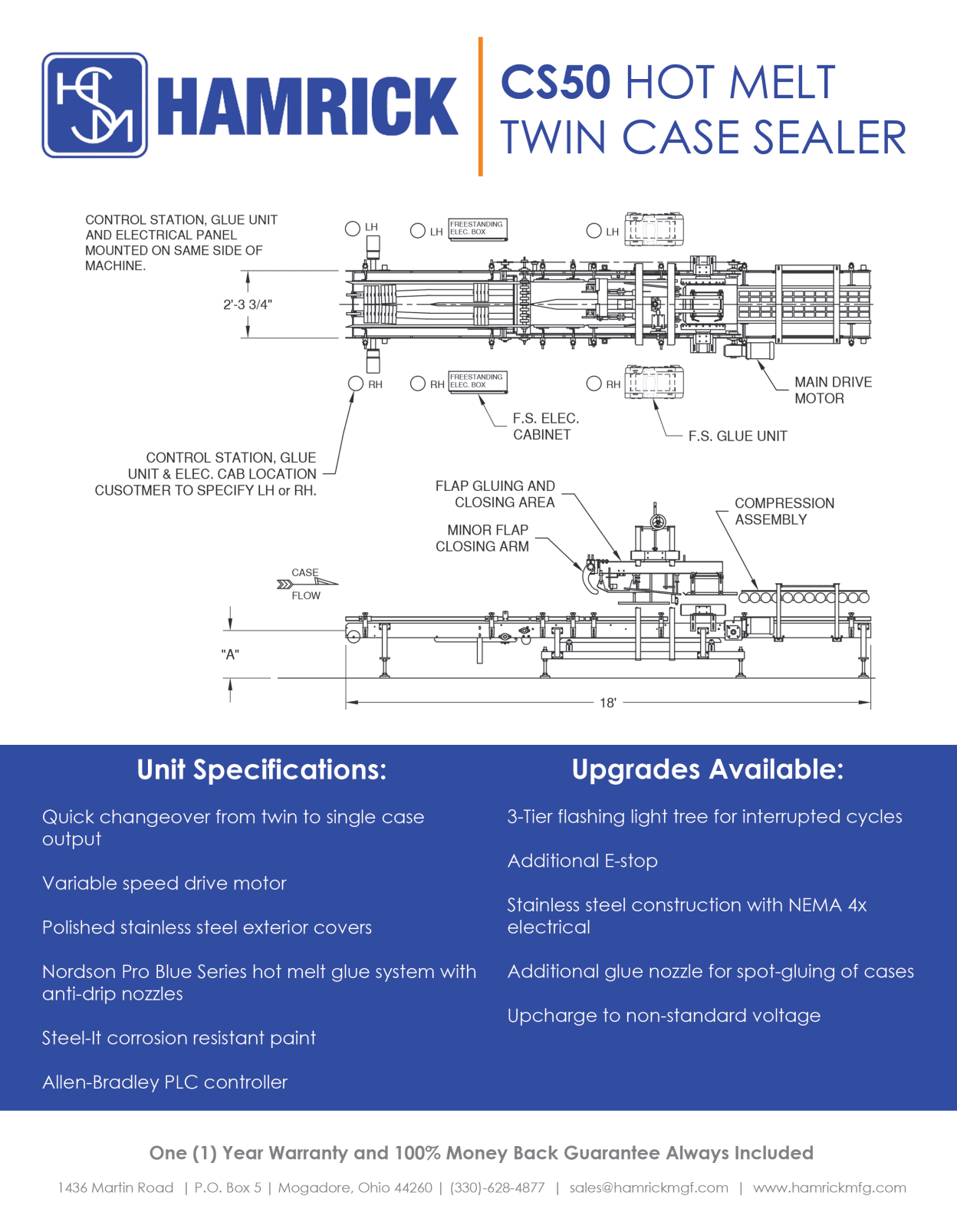

CS30 – Hot Melt Case Sealer is designed for quick changeover from twin to single case output and includes an Allen-Bradley PLC controller, a variable speed drive motor, and a Nordson Pro Blue Series hot melt glue system with anti-drip nozzles. This machine is designed for medium to high production volume and rated up to 30 cycles per minute.

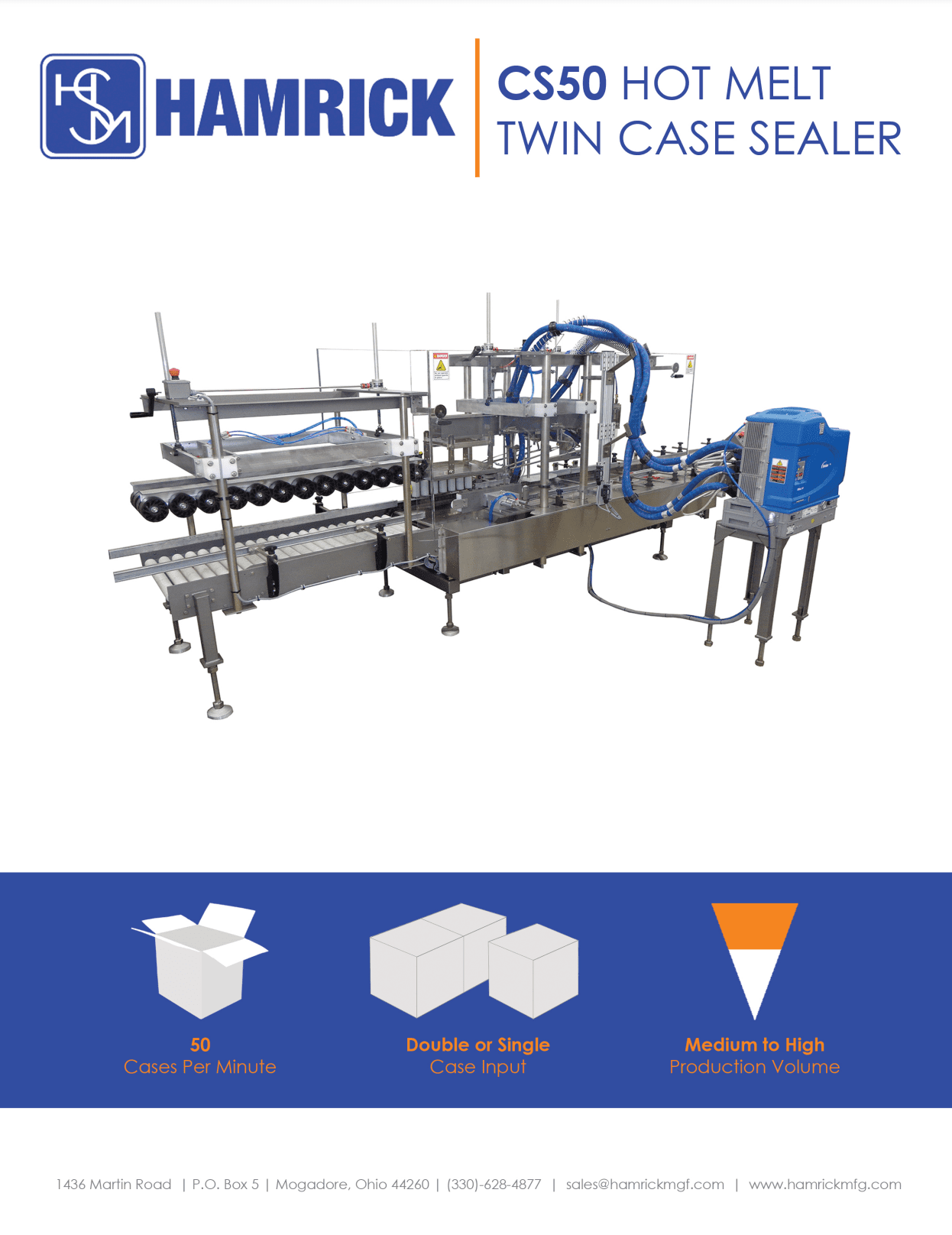

CS50 – Hot Melt Twin Case Sealer is virtually identical to the CS 30 machine with the exception it is rated up to 50 cycles per minute.

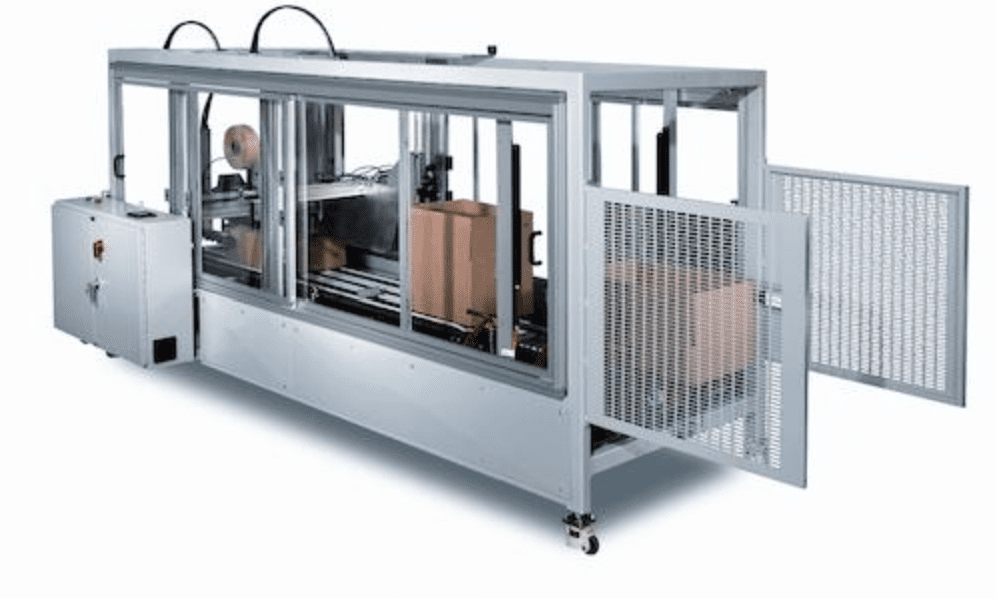

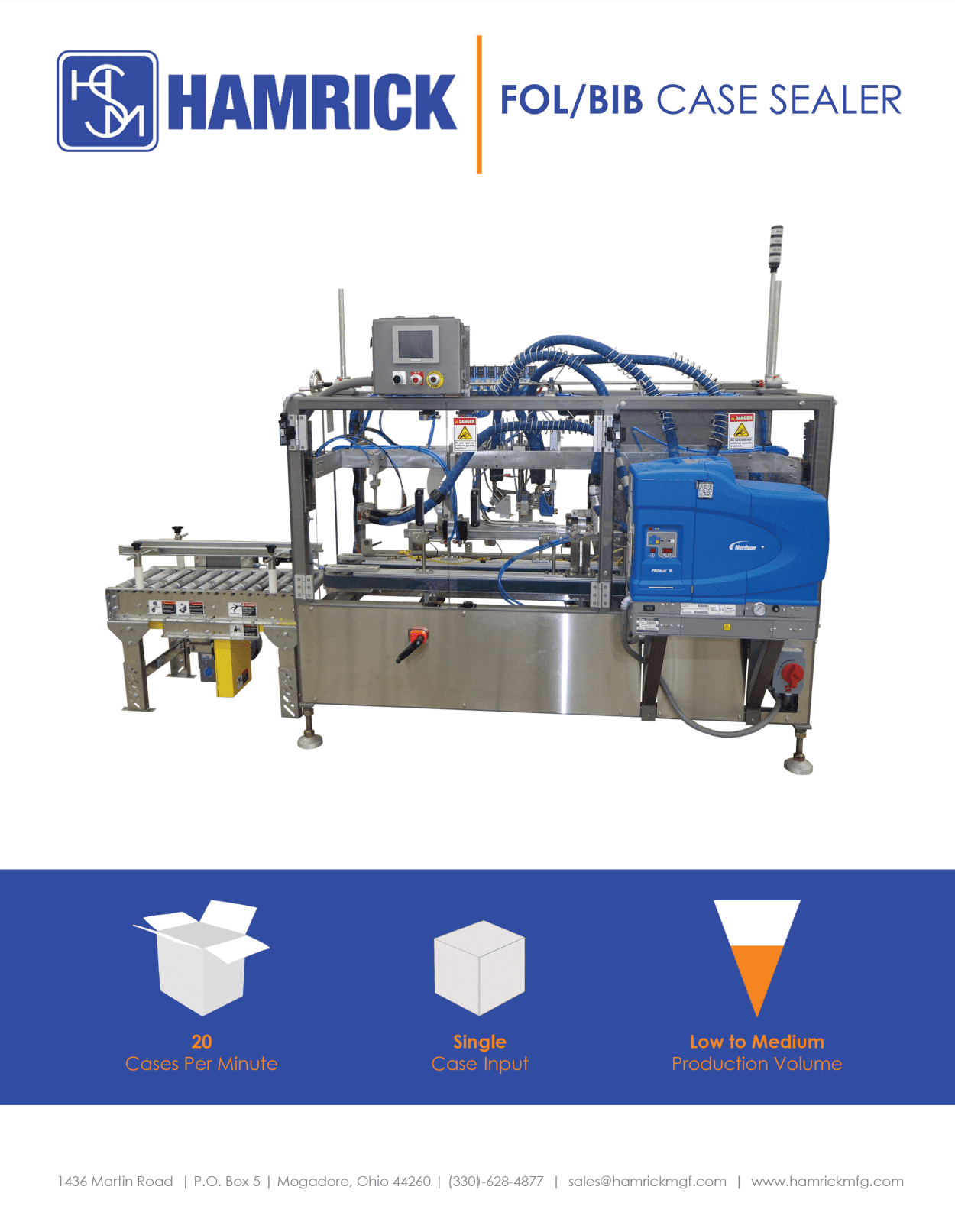

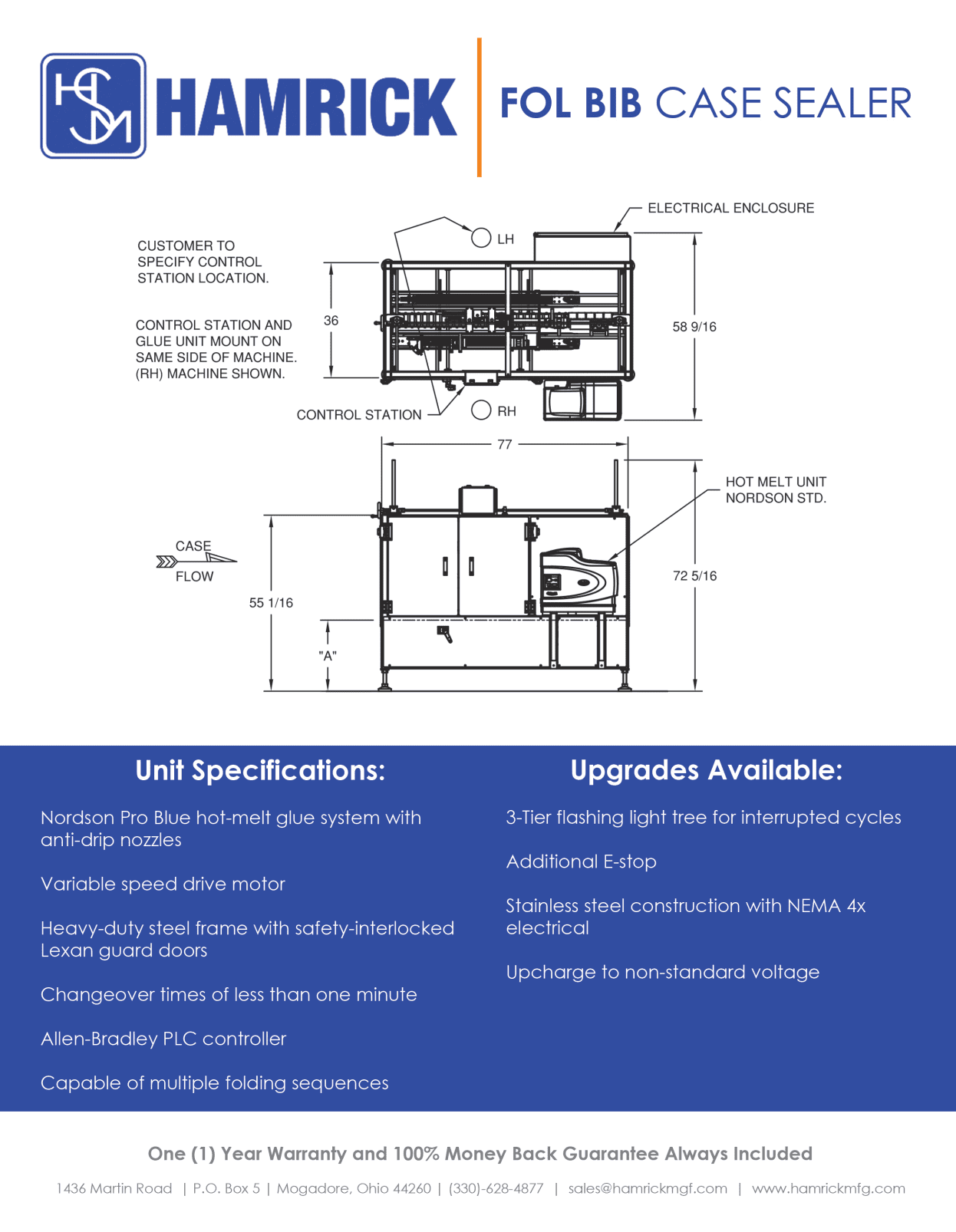

FOL & BIB Case Sealer is designed for multiple folding sequences with changeover times in less than one minute. This sealer has a heavy-duty steel frame with safety-interlocked Lexan guard doors, Allen-Bradley PLC controller, and Nordson Pro Blue hot-melt glue system with anti-drip nozzles. This machine is designed for low to medium production volume and rated up to 20 cycles per minute.

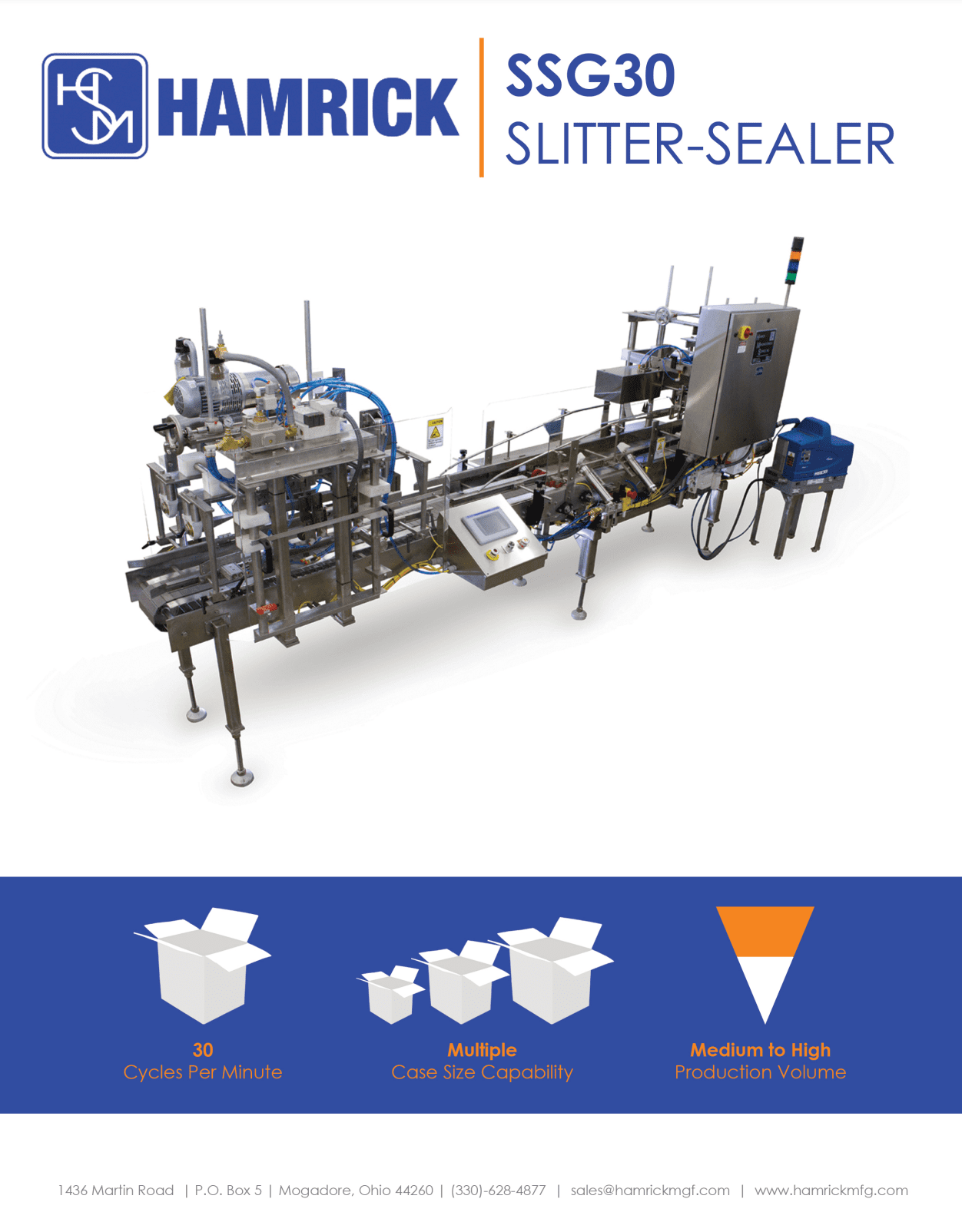

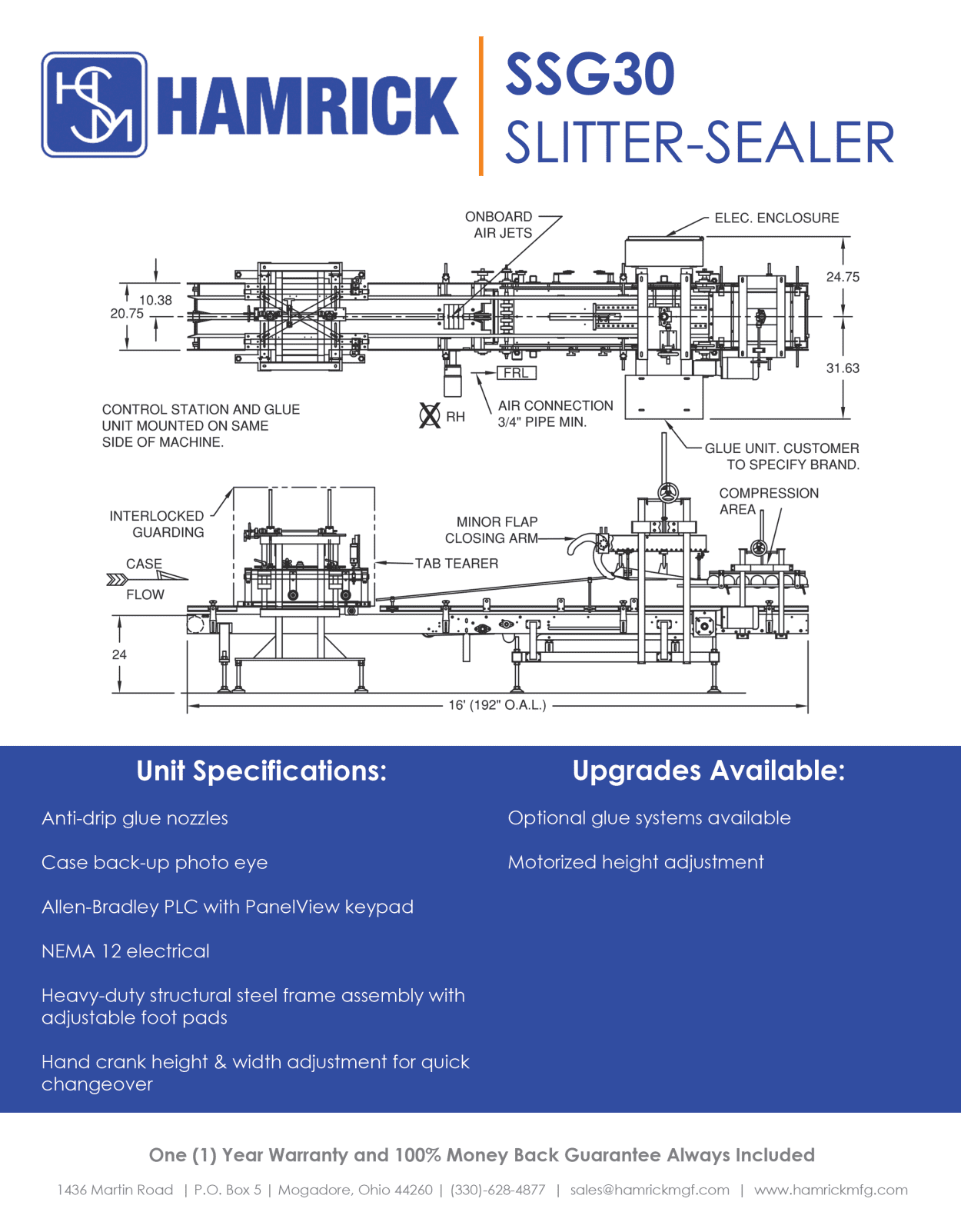

SSG30 Slitter – Case Sealer provides a heavy-duty structural steel frame assembly with adjustable foot pads and a hand crank height and width adjustment for quick changeover with multiple case size capacity. Additional features included are a Nema 12 electrical enclosure, Allen-Bradley PLC with panel view keypad, case back-up photo eye, anti-drip glue nozzles, and tab lock breaker, This machine is designed for medium to high production volume and rated up to 30 cycles per minute.

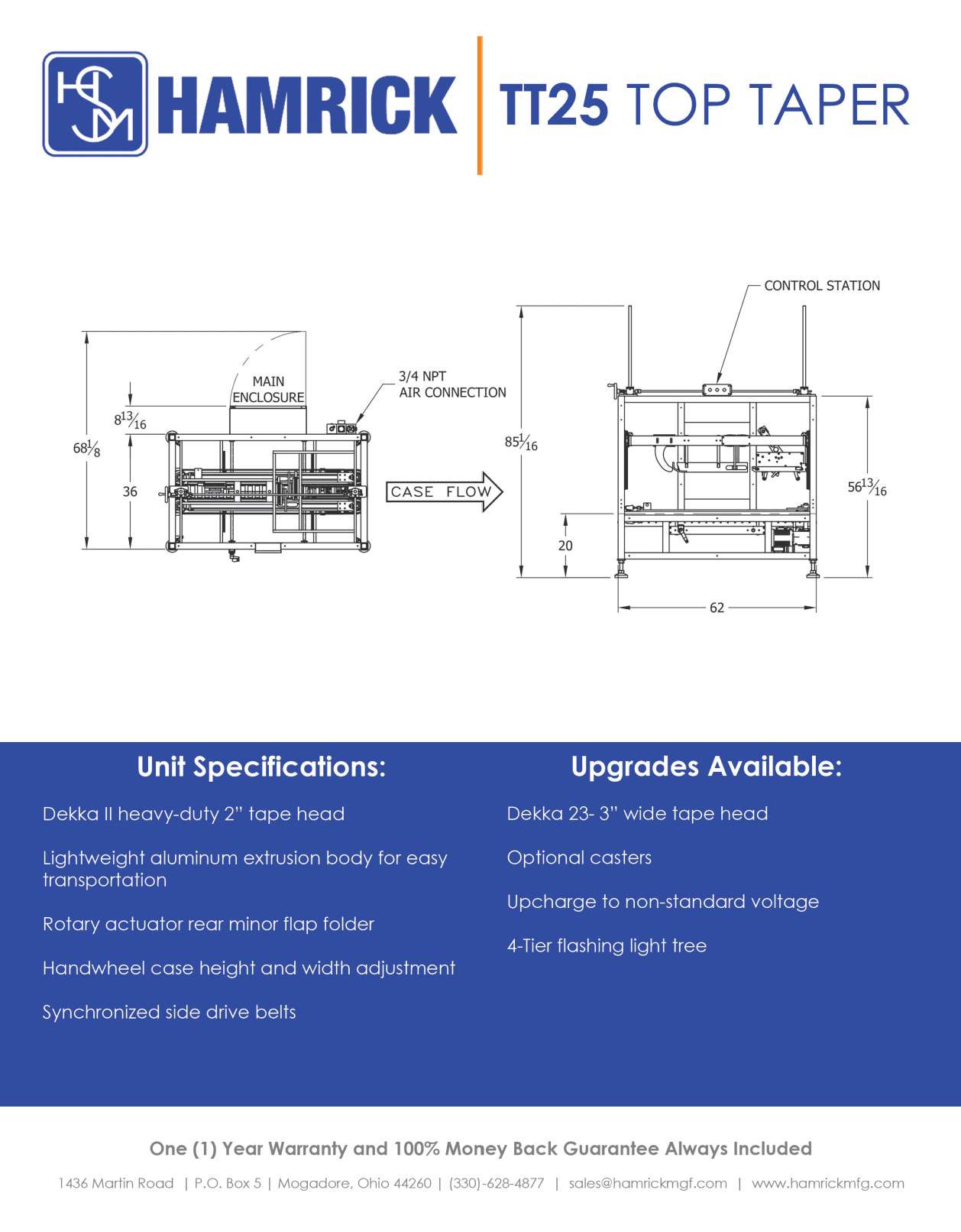

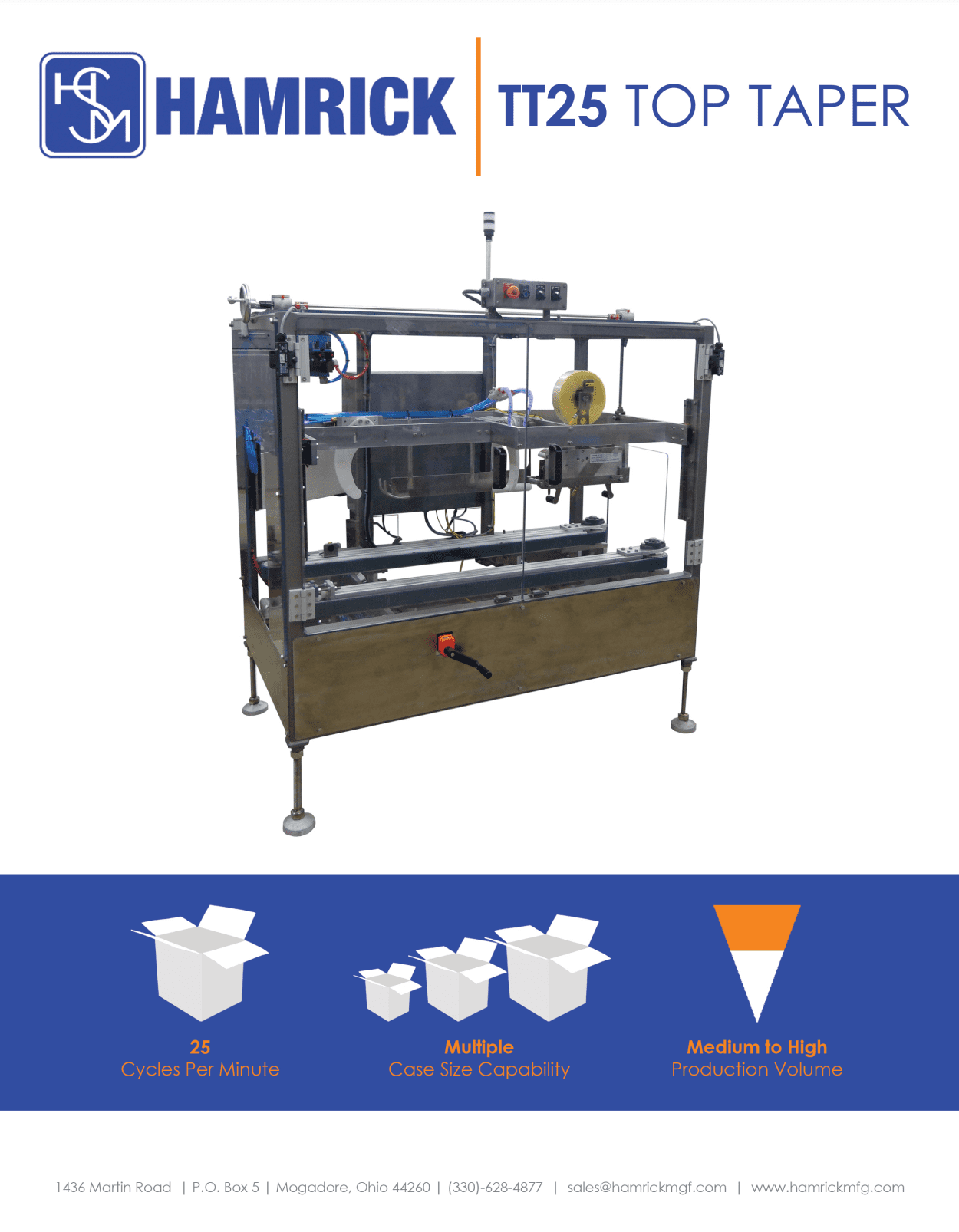

TT25 Case Sealer is designed to be portable giving you additional case sealing and multiple case size flexibility throughout your plant. Constructed with a lightweight aluminum extrusion body for easy transportation, synchronized side drive belts, handwheel case height and width adjustment, rotary actuator rear minor flap folder. and Dekka II heavy-duty 2″ tape head. This machine designed for medium to high production volume and rated up to 25 cycles per minute.