What Case Packer is Best for You?

Case Packer Machines

Looking to increase operational efficiency packing products?

Case packing machines help you be more productive by packing products quickly and efficiently. We manufacture simplicity, durability, and versatility in each machine. Designed with simple operator controls, the functionality to incorporate different product styles and engineered to the highest durability standards in the industry

We offer a range of case packer machines that are designed for a quick and simple changeover process and to limit downtime. While low-cost change parts enable customers to run multiple products on the same line.

Whatever your type of product, packing patterns, rate of speed, space constraints, semi to fully automatic or robotic applications may be, we can help streamline and guide you to achieve maximum performance within your budget.

Semi and Fully Automatic Case Packer Machines

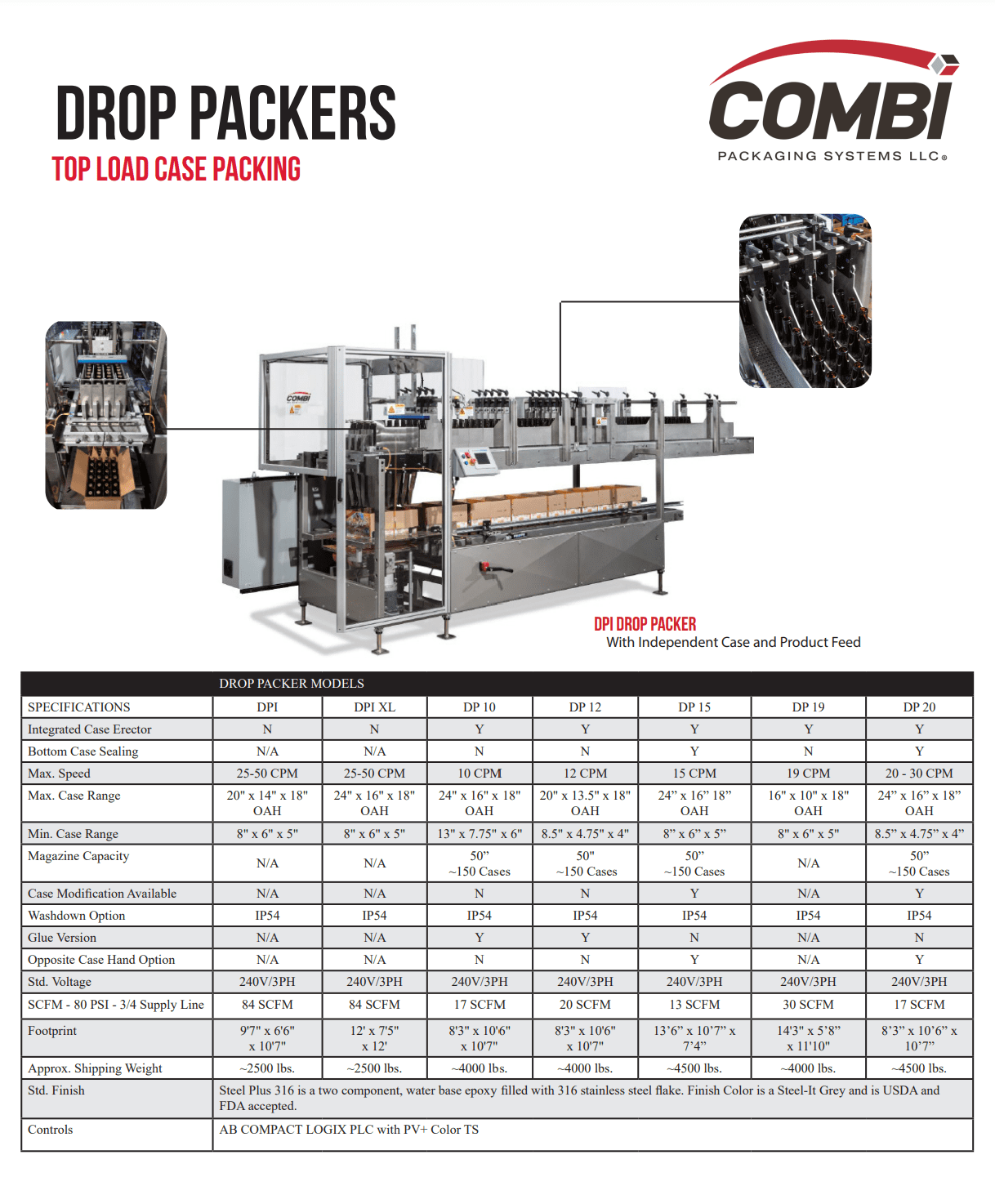

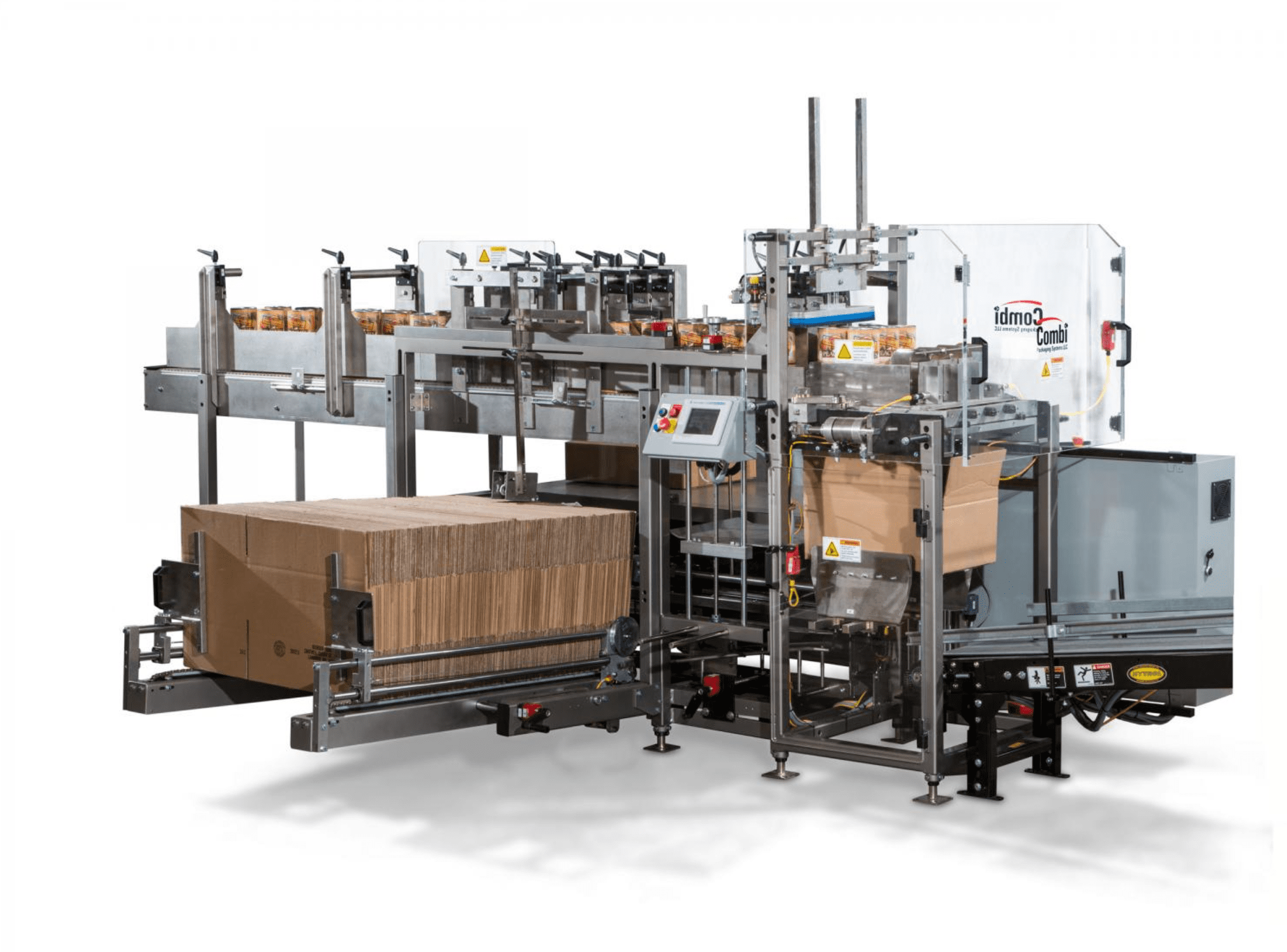

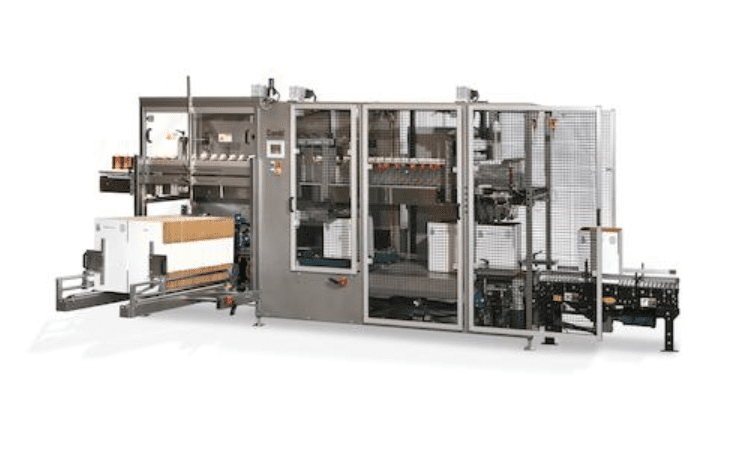

Drop Load Case Packer

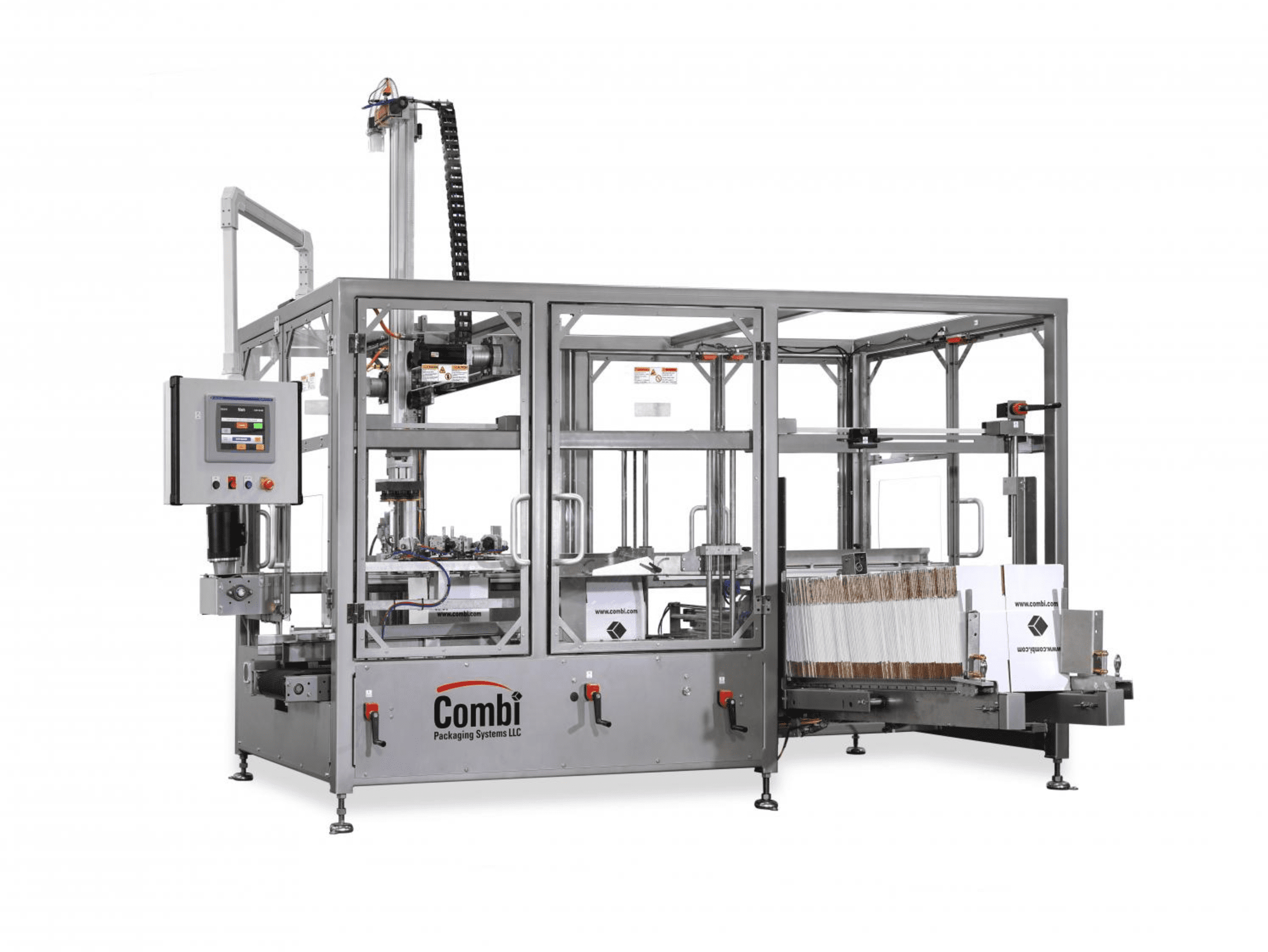

Combi Drop Load Case Packer

Combi Packaging Drop Load Case Packer

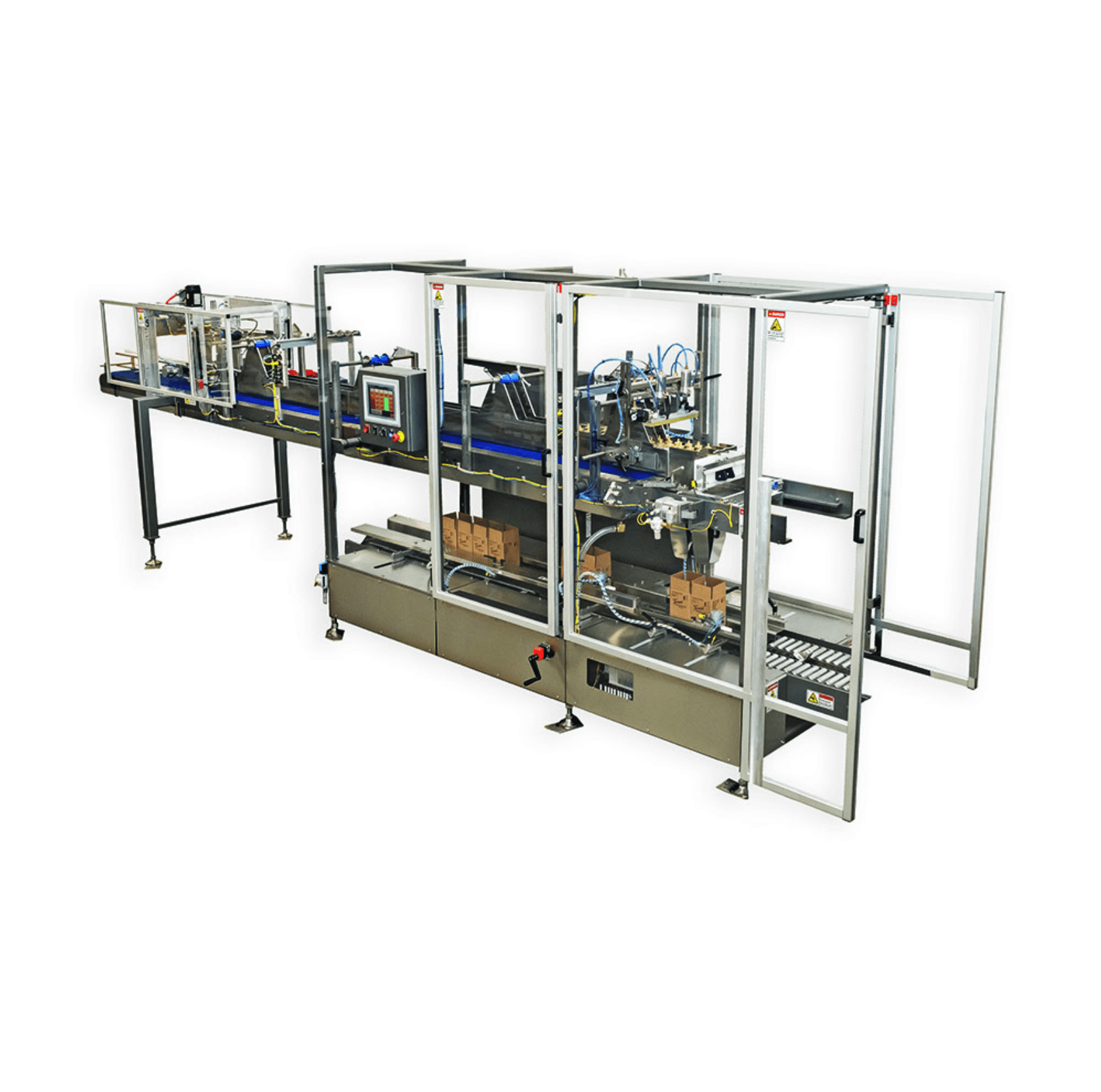

Drop Load Case Packer with Case Erector is a compact solution for a wide range of rigid containers and easily integrates with our case erector and the drop load packer in a small footprint. This system is rated up to 10-30 cases per minute.

Drop Load Case Packer with Bull Nose Conveyor is designed for packaging of flexible pouches and bags with a flexible bag and pouch shingling system where the package is auto fed onto a belt conveyor that extends and retracts – shingling the product as it drops onto a bay door or dropping one layer at a time, in a pre-determined pattern.

DPI Stand Alone Case Packer is a heavy duty, welded tubular stainless steel construction and fast changeovers with modular slide-in packing heads, and quick clamp product lane guides. This system is rated for 25-50 cases per minute.

High Speed Drop Load Case Packer with Integrated Case Erector offers a larger variety product sizes, shapes, weights and materials that can be quickly and easily packed in large cases. Adjustable lane guides with clamping shaft collars can be quickly, easily, reconfigured using pointers and scales, giving the user the flexibility to pack multiple products on the same line. This system is rated up to 30 cases per minute.

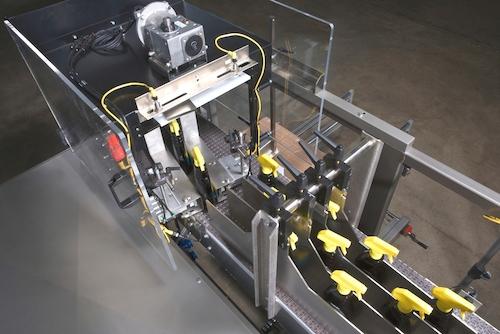

Servo Multi-Lane Product Diverter counts and indexes product from one lane up to 8 individual lanes, while maintaining orientation and constant product flow. It can divert up to 240 containers per minute and is used primarily for non-round bottles and cans. We include a safe shifting “anti-jam” design, no tool adjustments, and is also available as free standing unit over existing conveyor.

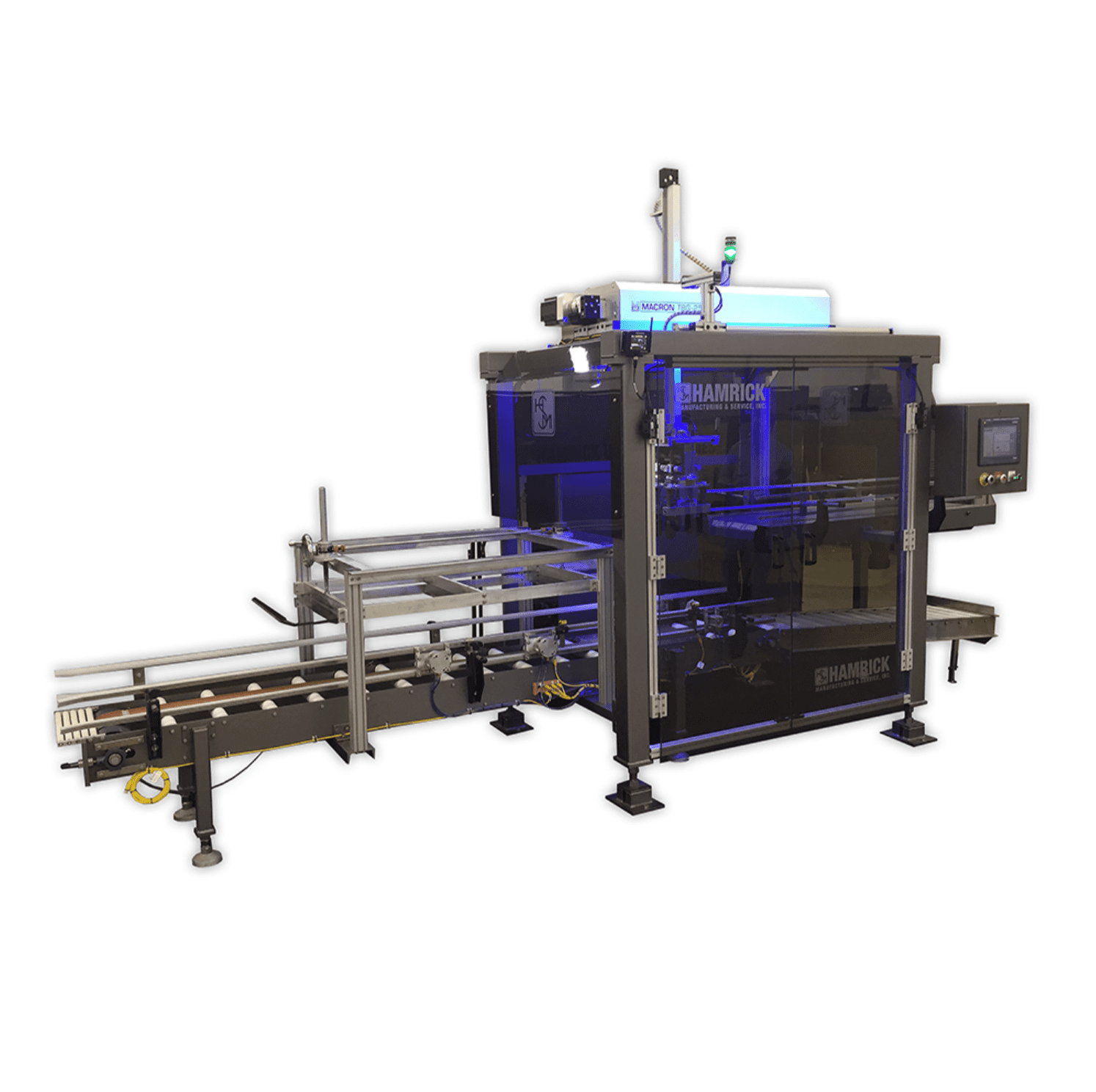

Hamrick Drop Load Case Packer

Hamrick Packaging Systems Drop Load Case Packer Machine

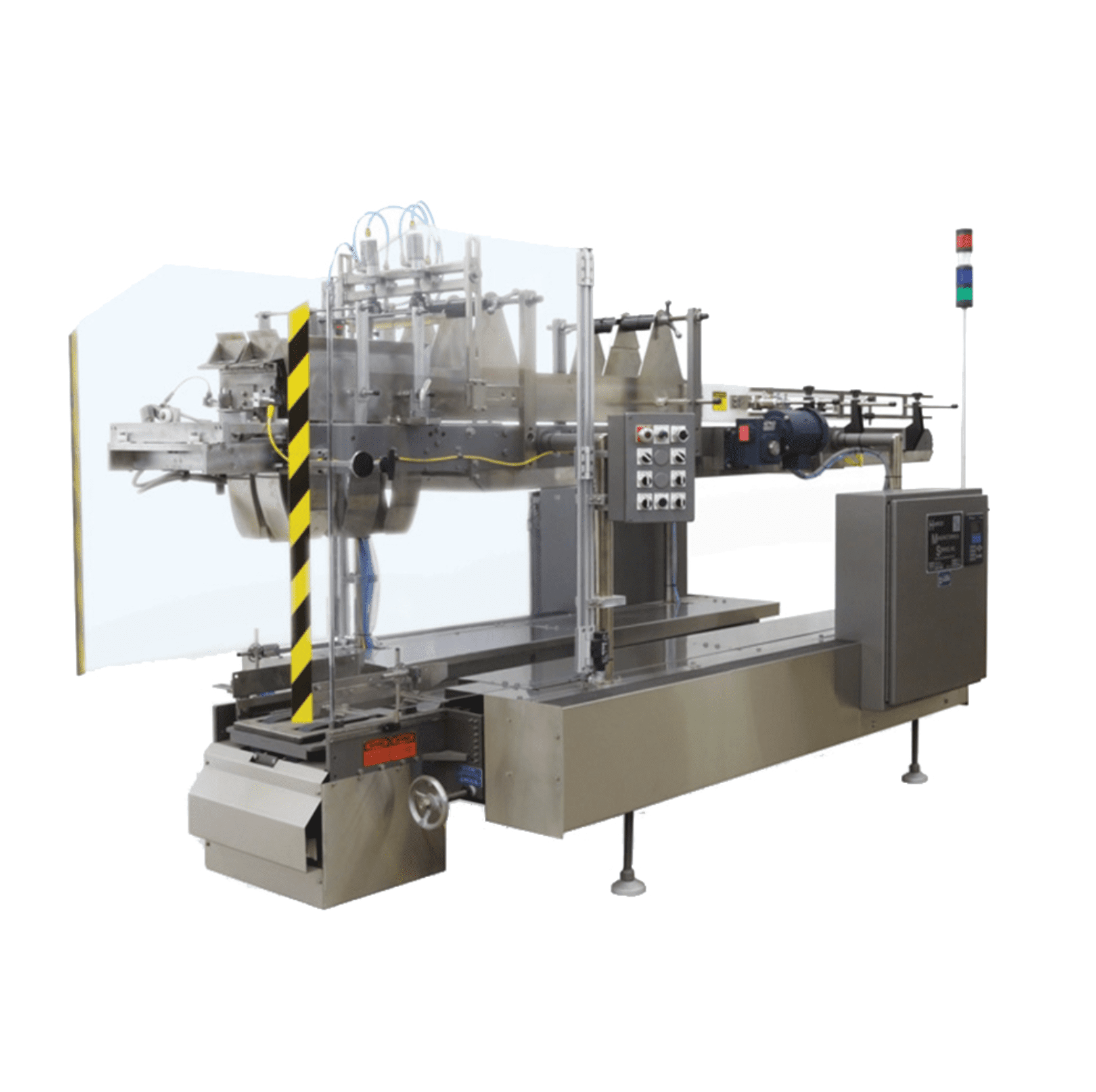

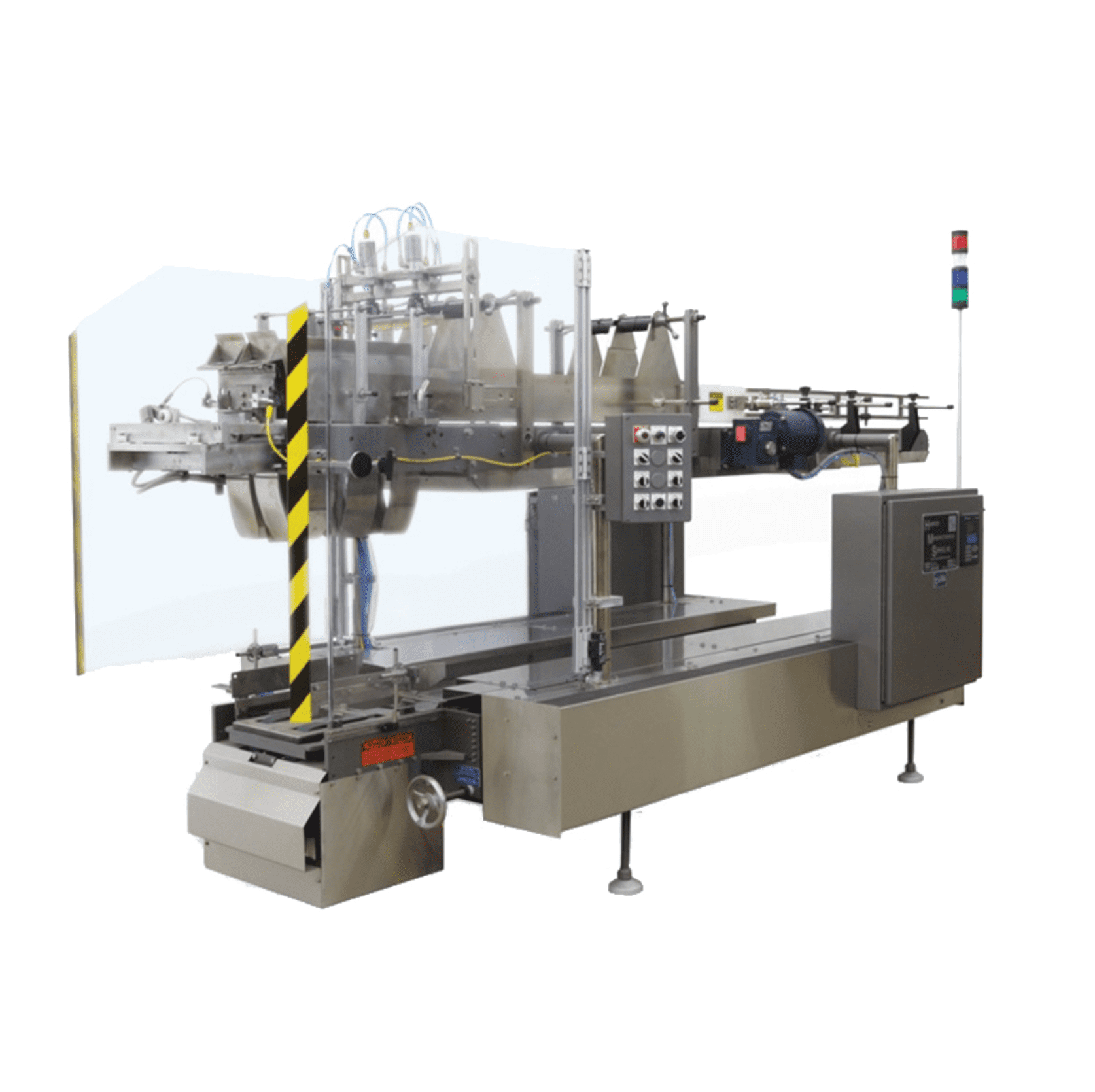

The Hamrick drop load case packer is manufactured with three principles in mind; simplicity, versatility, and durability. Designed with simple operator controls, the functionality to incorporate different product styles, and engineered to the highest durability standards in our industry.

Our case packers have speeds ranging from 15-60 cycles per minute and can run most rigid containers (metal, glass, and plastic) in various pack patterns. A quick and simple changeover process allows our customers to limit downtime, while our low-cost change parts enable them to run multiple products on the same line.

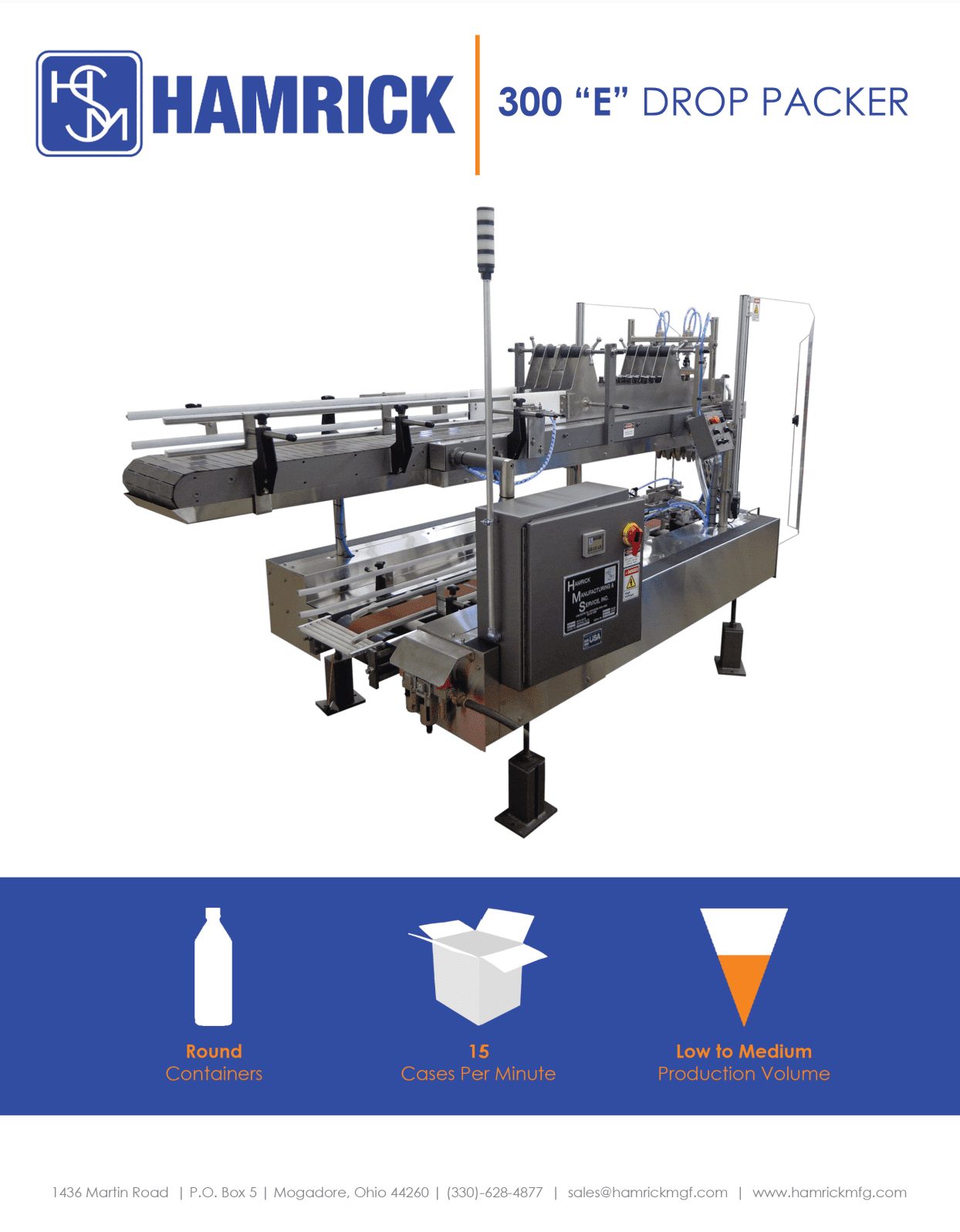

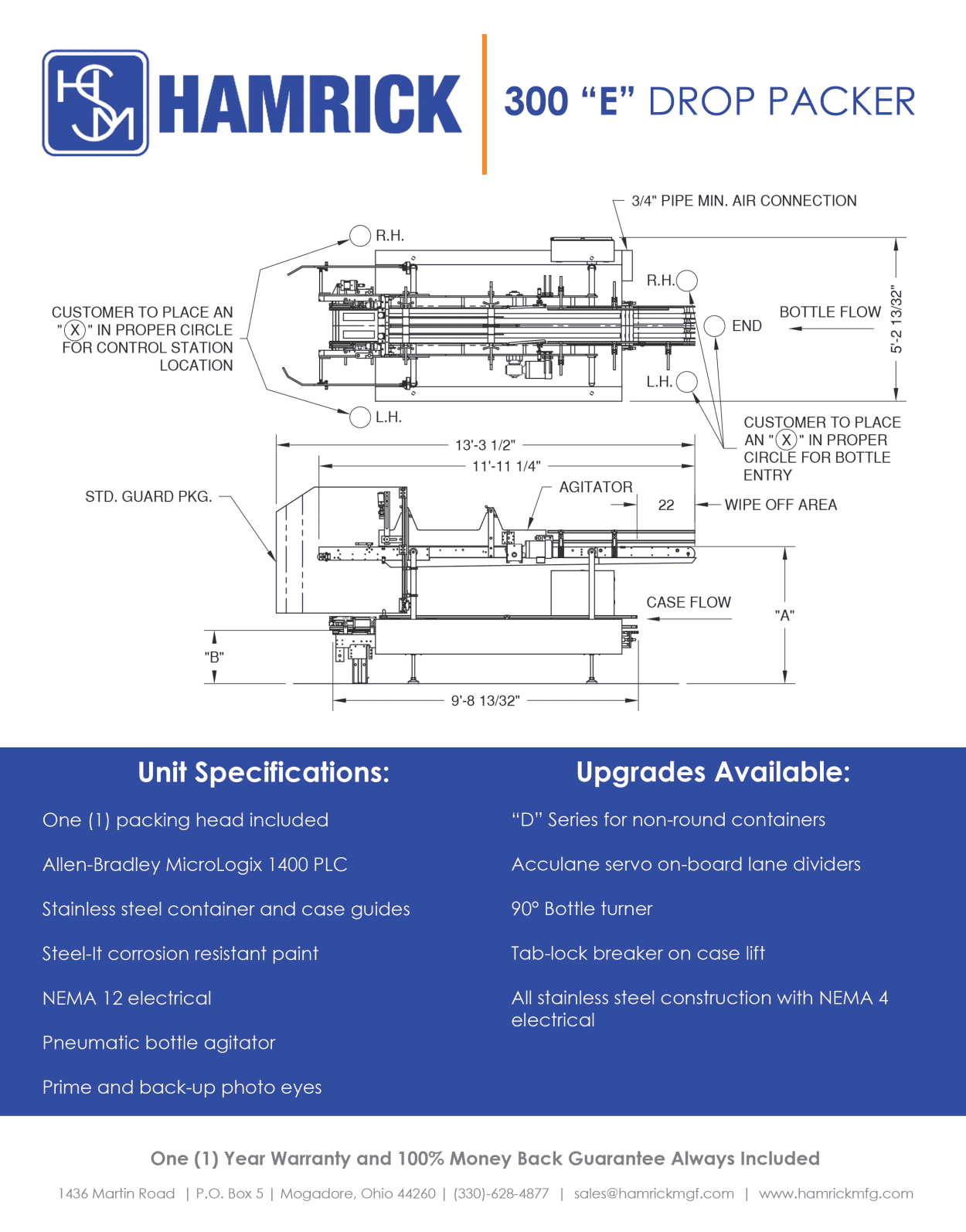

Model 300E is a drop load case packer designed for round containers only requiring a low to medium production volume at speeds up to 15 cycles per minute.

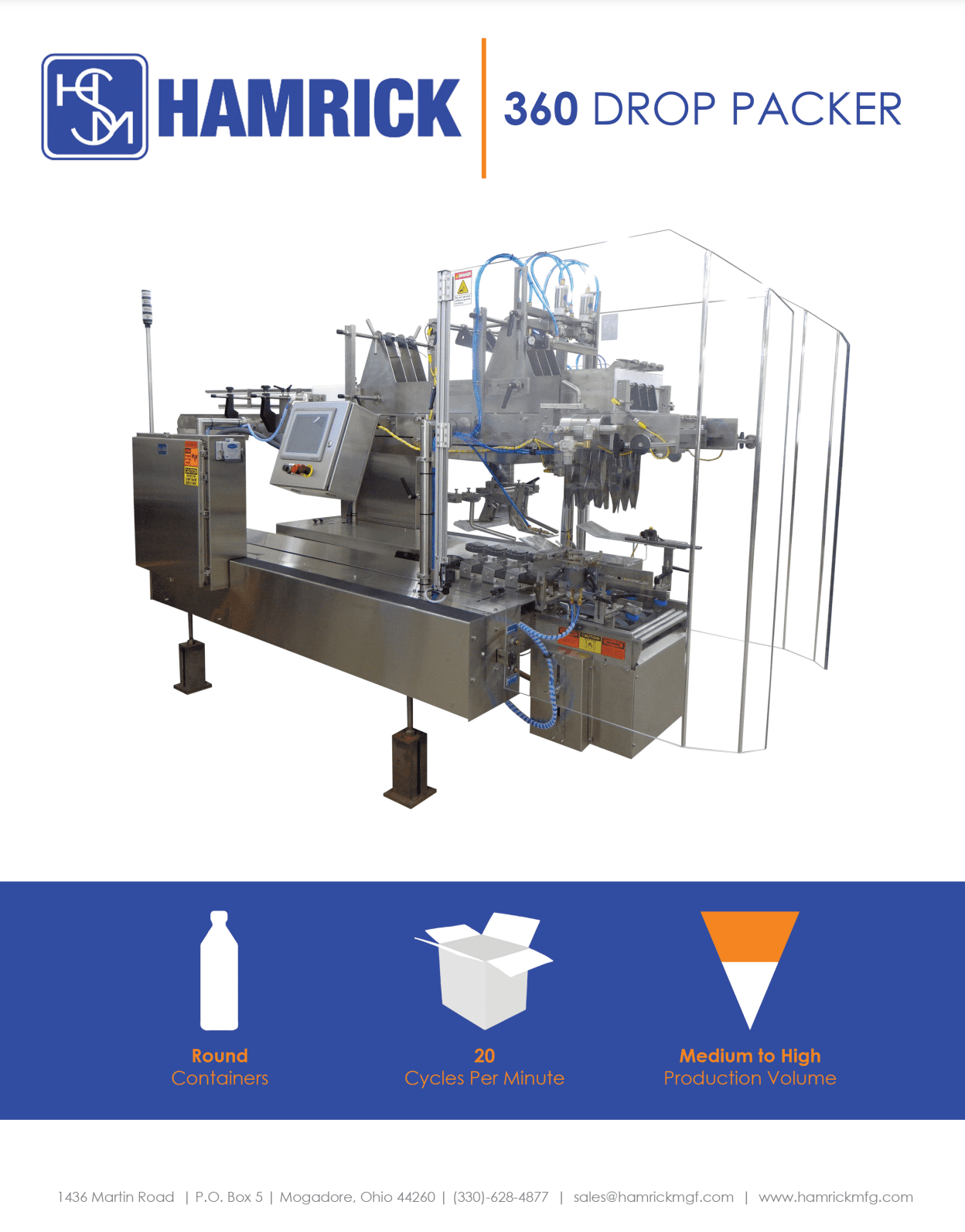

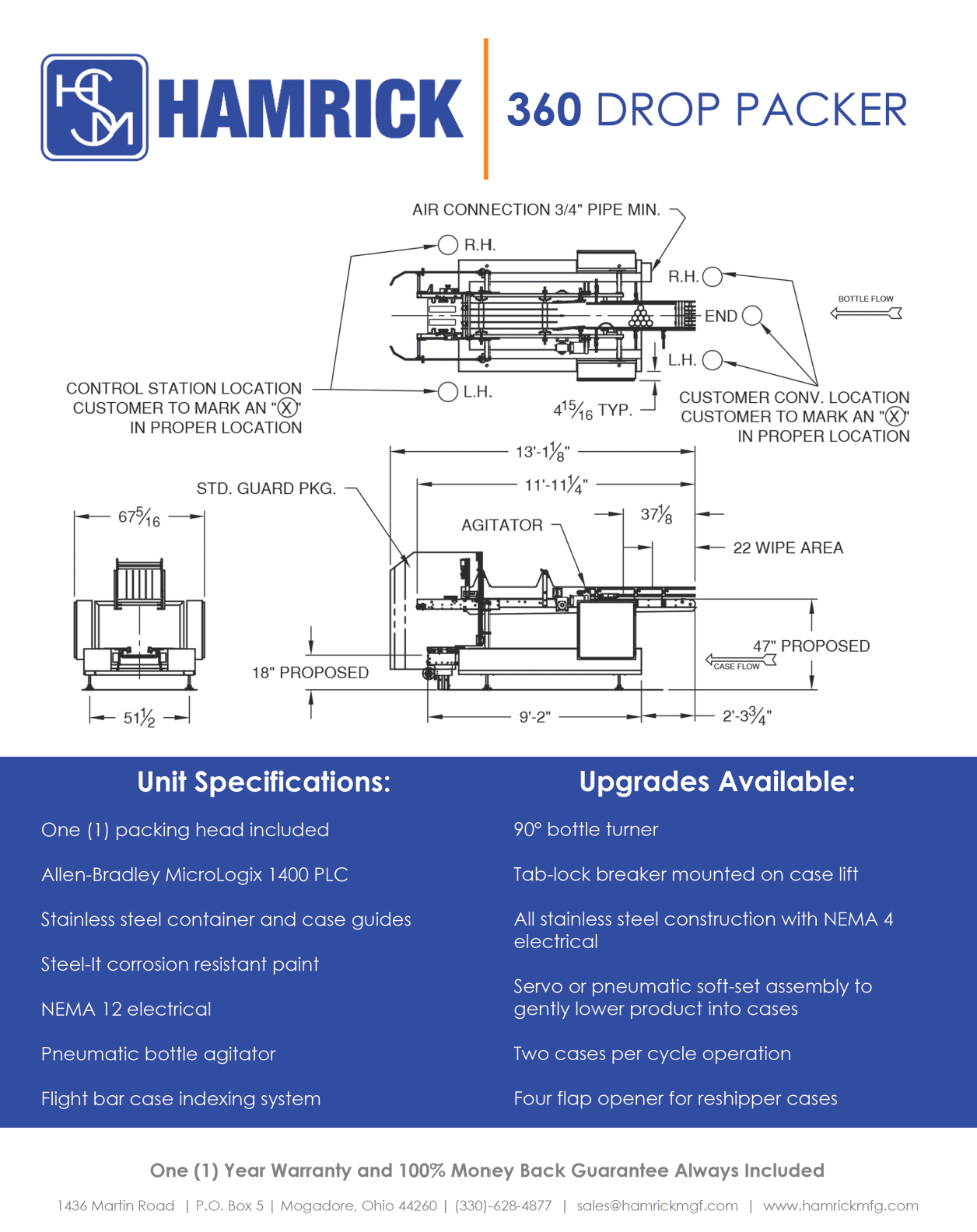

Model 360 is a drop load case packer designed for round containers only for medium to high production volume at speeds up to 20 cycles per minute.

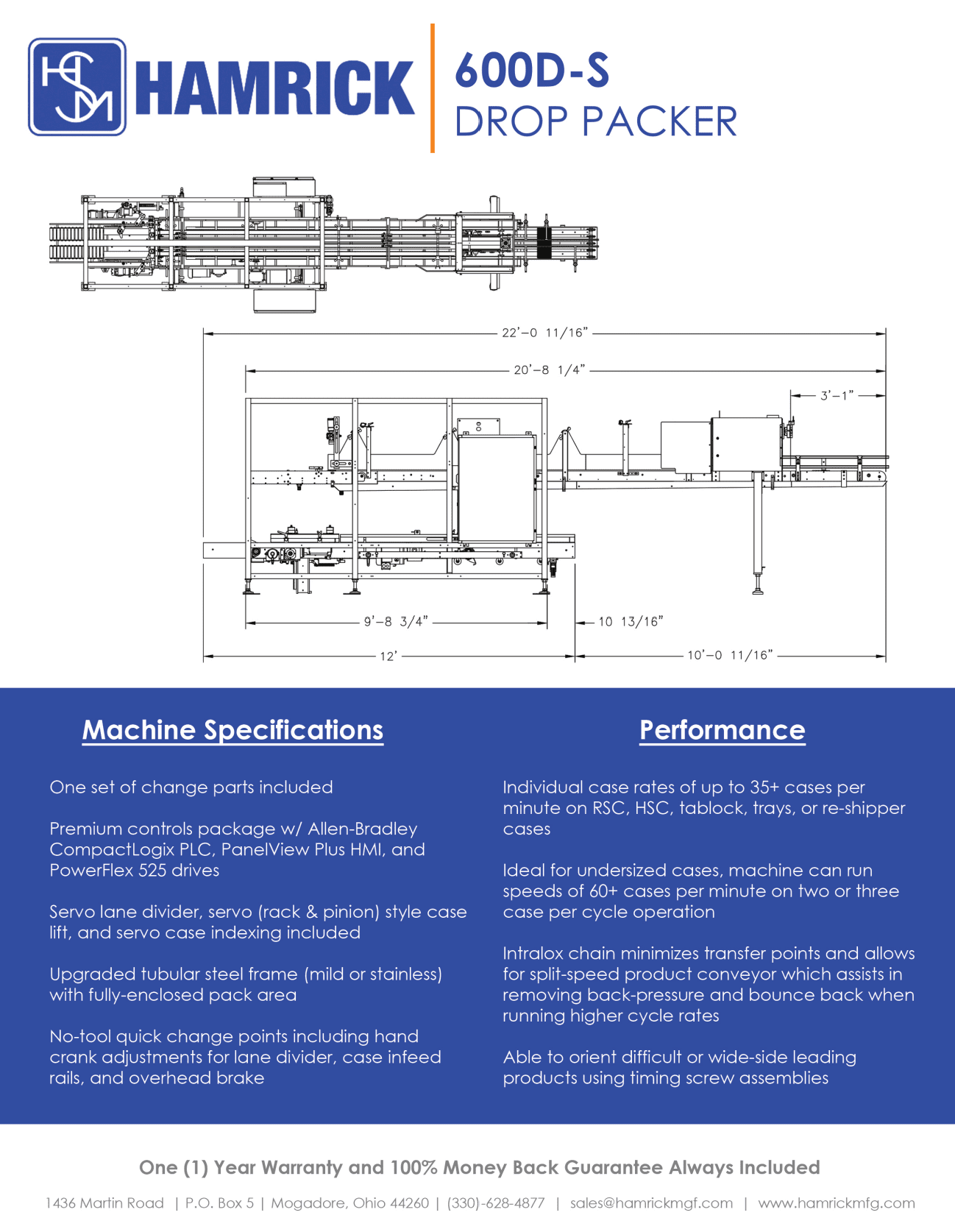

Model 600D-S is designed with all servo controls, operates as a high speed drop load case packer designed for round or non-round rigid containers. We provide an integrated servo-controlled belt-style lane divider which is ideal for undersized cases and high speed packaging. This case packer speed is rated up to 30 cycles (60+ cases) per minute.

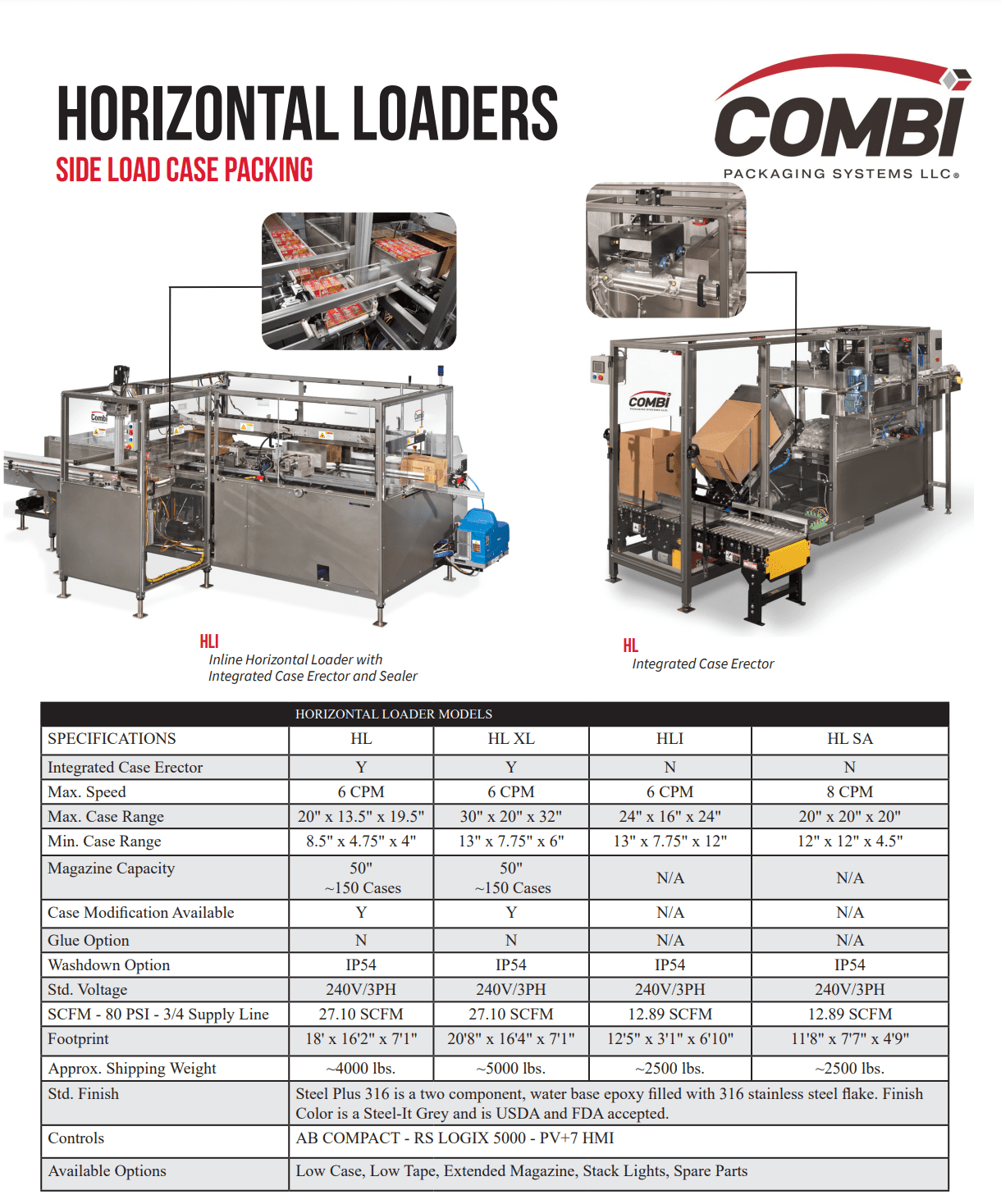

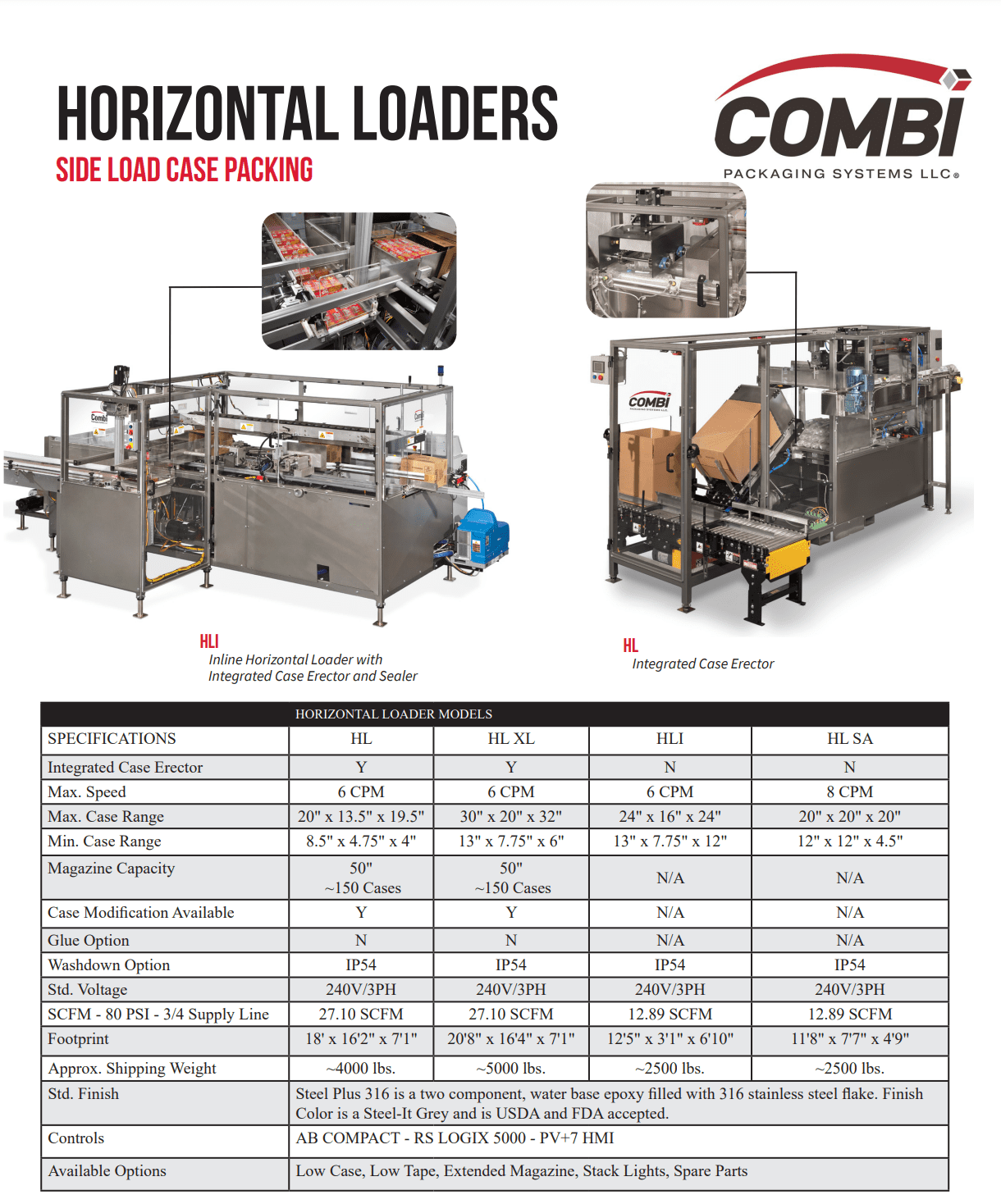

Side Load Case Packer

Combi Packaging Side Load Case Packer

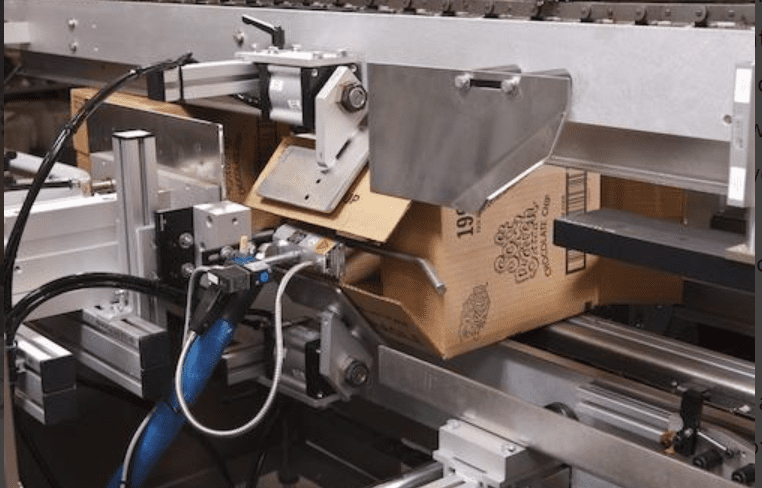

The HL Side Loader Case Packer Machine system provides flexibility by opening, loading and sealing a case laying horizontally, thereby decreasing the footprint of the integrated system and accommodating a wider range of products. The HL is integrated with the Combi CE case erector and also features a sealer equipped with your choice of pressure sensitive tape or hot melt glue. Whether your product requires up stacking, down stacking, or progressive collation, the compact HL is adaptable to your product and your floorspace requirements.

CHL Automatic Side Loader Case Packer Machine is a fully automatic side loader case packer machine system integraed with our E-series case erectors. The HL is an excellent system for a diverse range of products, accommodating a wide range of case sizes and pack patterns on the same machine. The HL features a simple modular design and few change parts, assuring fast changeovers and minimal downtime. This system is rated at 6-8 cases per minute.

Horizontal Load Case Packer

Combi Packaging Horizontal Load Case Packer

The CHL is integrated with the Combi HCE case erector and also features a sealer equipped with your choice of pressure sensitive tape or hot melt glue. Whether your product requires up stacking, down stacking, or progressive collation, the compact CHL is adaptable to your product and your floorspace requirements.

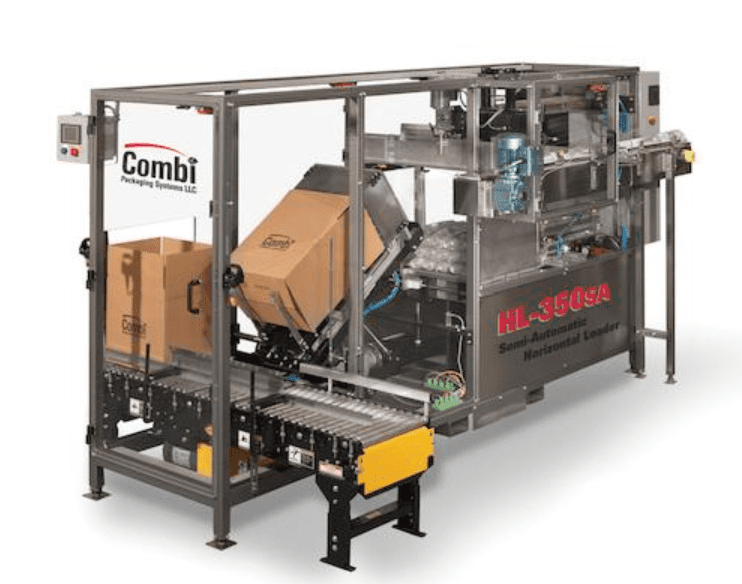

HL SA Horizontal Loading Case Packer Machine is offered as a semi-automatic or fully automatic side load case packer system. Integrated with our E-series case erector, the HL is an excellent system for a diverse range of products, accommodating a wide range of case sizes and pack patterns on the same machine. We feature a simple modular design and few change parts, assuring fast changeovers and minimal downtime.

The HL SA semi-automatic horizontal loading case packer system allows one worker to attend to many tasks on the line. Cases are manually erected prior to automated packaging. The higher speed HL horizontal loading case packer provides flexibility by opening, loading, sealing a lie flat horizontal case. This automated packaging system is integrated with the Combi HCE case erector and features a case sealer equipped with your choice of pressure sensitive tape or hot melt glue.

CHL Horizontal Loading Case Packer Machine is a case packer system that provides flexibility by opening, loading and sealing a case laying horizontally, thereby decreasing the footprint of the integrated loading system and accommodating a wider range of products. The horizontal loading solutions allow for many pack patterns and product sizes on the same machine and offers many collation methods for product grouping and orientation.

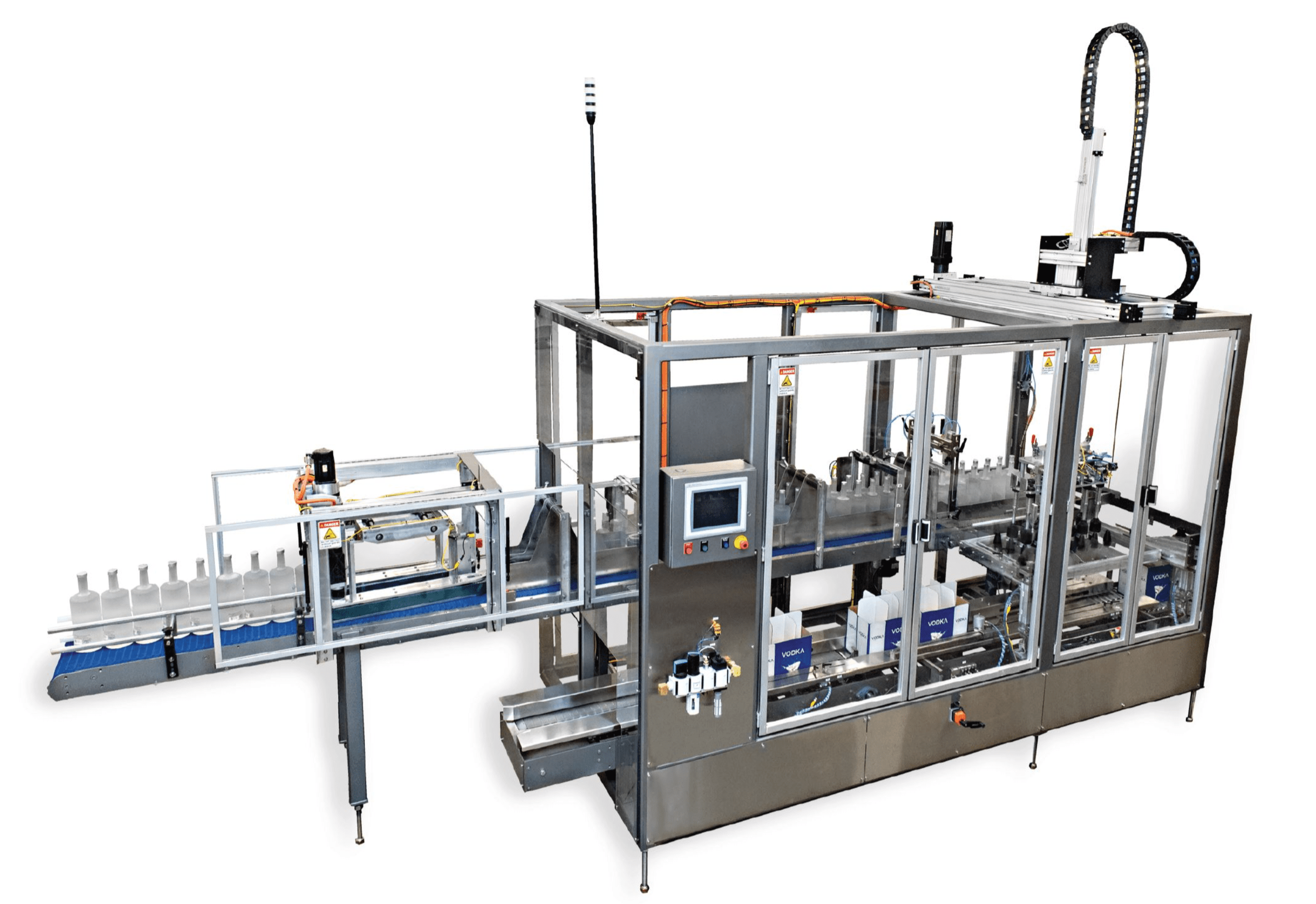

Pick & Place Case Packer

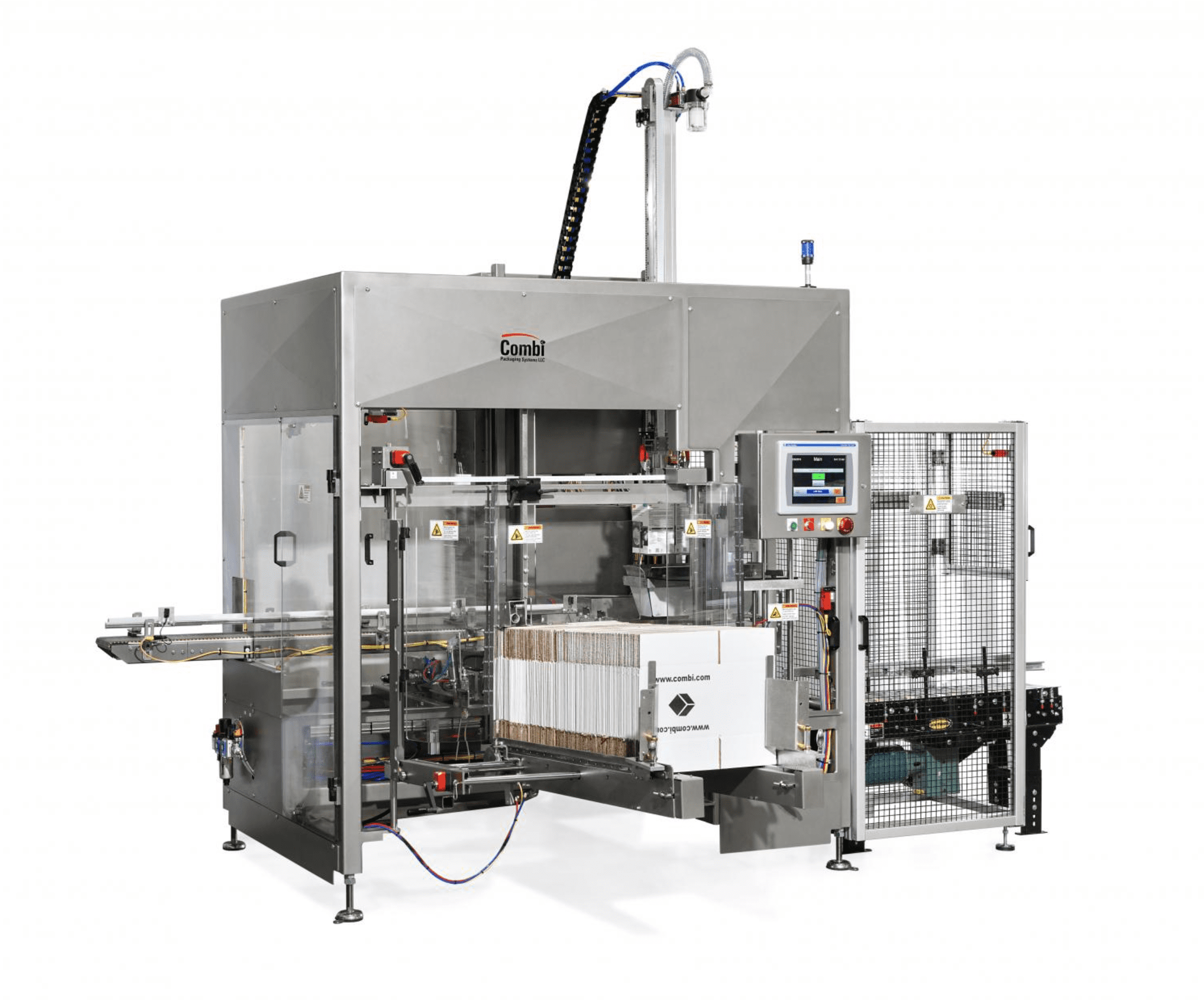

Combi Pick & Place Case Packer

Combi Packaging Pick & Place Case Packer

Alphapack Pick and Place Case Packing Machine is the new productivity solution for Pick & Place case packing. It includes and features a case erector and accommodates the widest range of case sizes and pack patterns. In addition, it yields the smallest footprint in the industry, handles special orientation or precise packaging, and packs flexible pouches and bags packaging with multiple layers.

Alphapack HS Pick and Place Case Packer is our number one selling pick & place case packer and is now offered with an integrated with a high speed 2-EZHS case erector. The system features heavy-duty tubular steel construction, integrated touchscreen controls and diagnostics, linear servo system capable of 25 picks per minute. This compact case packer ideal for top loading products in multiple layers into corrugated cases and can accommodate a wide range of case sizes and pack patterns. Compared to manual case packing, this packaging equipment will increase your throughput while lowering labor costs.

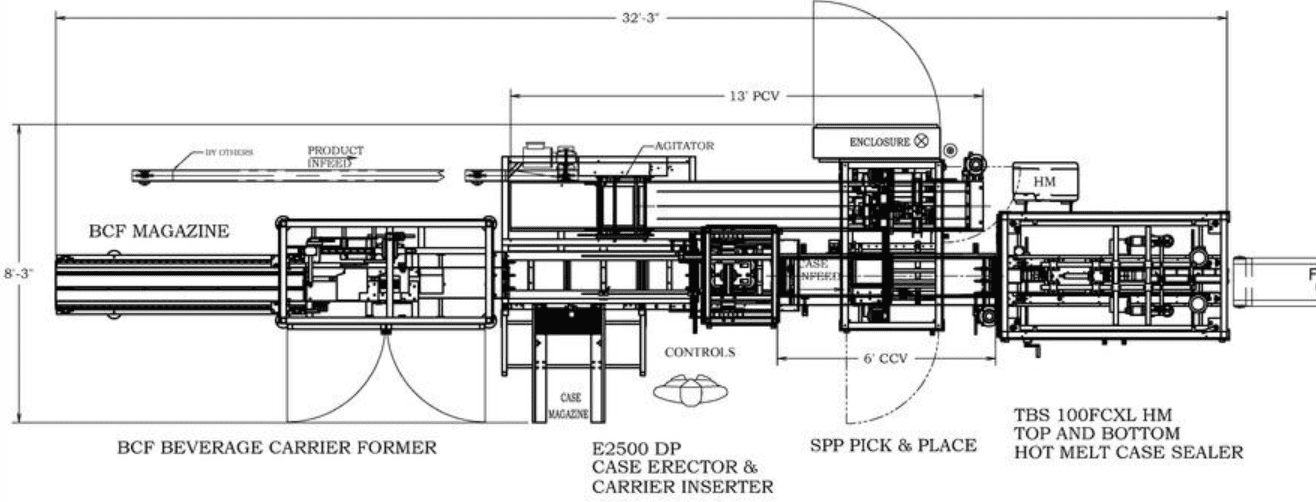

Compact SPP Beer Bottle Case Packer is a servo pick and place beer bottle case packer with a top load case packer system featuring heavy duty linear servo motors capable of 25 picks per minute or case packing 100-120 bottles per minute. Integrated with our E2500 case erector and BrewPack Carrier Former and Inserter, the BrewPack case packer has a compact foot print for fitting into the tightest packaging lines.

High Speed BCF SPP Bottle Case Packer is a high-speed end of line bottle case packing system for brewers experiencing growth. Our high speed automatic beer bottle packing system erects a six or four pack carrier, the RSC case, inserts four carriers into the case, case packs the bottles and case seals the top and bottom flaps with your choice of adhesive tape or hot melt glue. This robust system maintains a throughput of up to 300 BPM.

SPP Pick and Place Case Packer is a servo pick and place top loading case packer featuring heavy duty linear servo motors capable of 25 picks per minute. Integrated with the E-series case erectors, the servo pick and place case packer has a compact footprint for fitting into the tightest packaging lines.

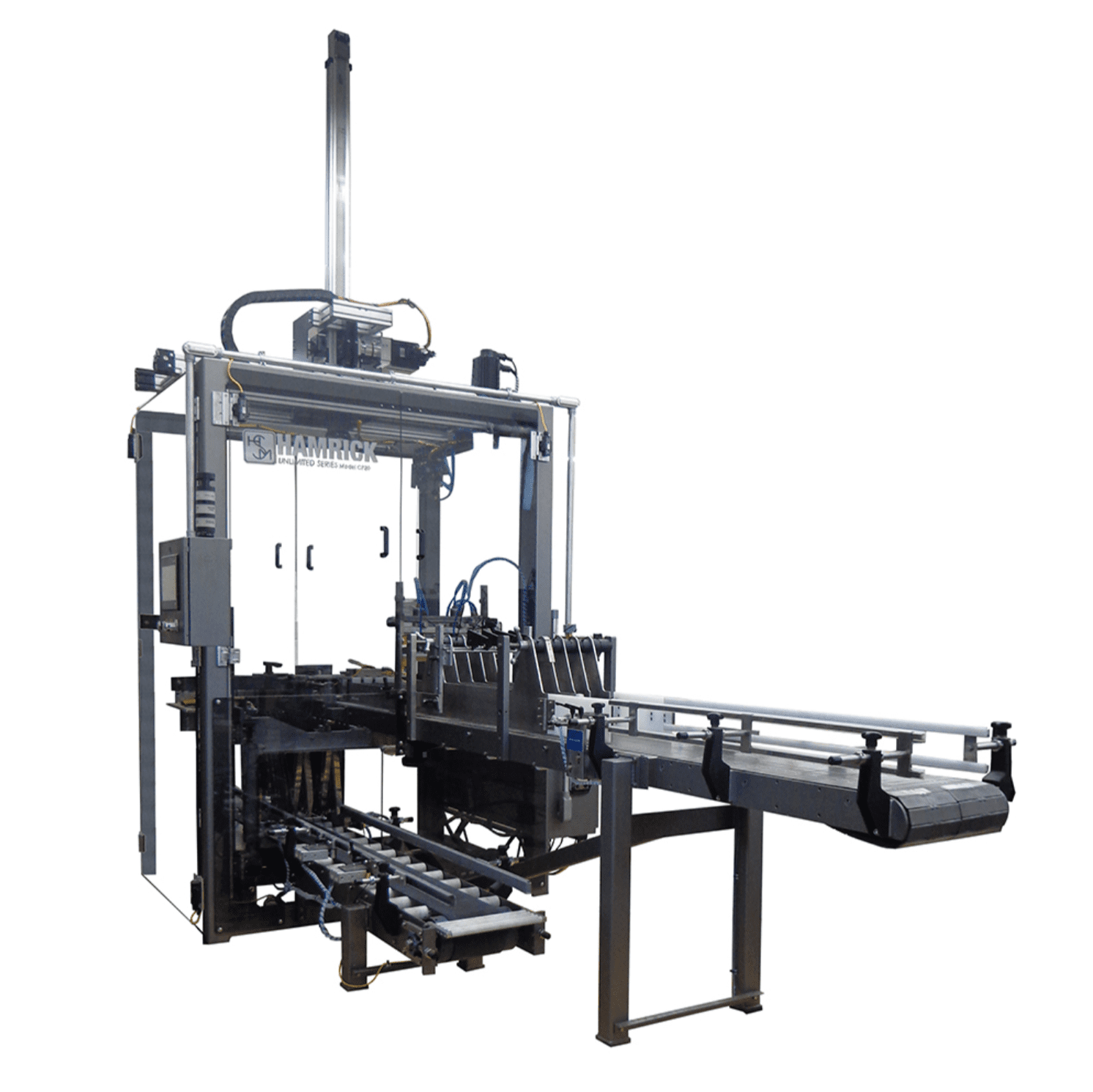

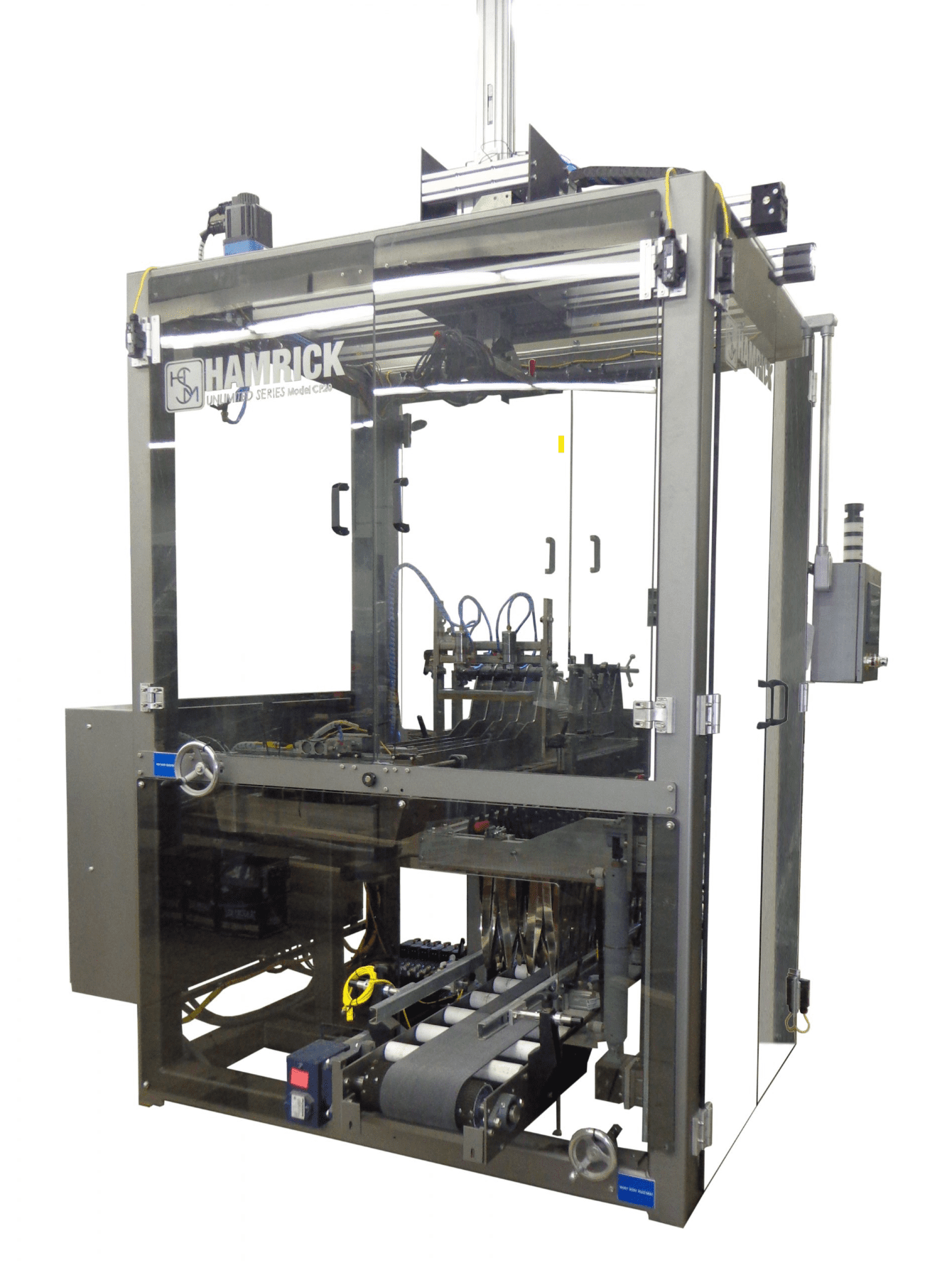

Hamrick Pick & Place Case Packer

Hamrick Packaging Pick & Place Case Packer

CP15 Pick & Place Case Packer allows for gentle packing of fragile product using a servo controlled two-axis overhead pick & place. It includes tooling featuring gripper, vacuum or bladder assemblies. Features single case infeed with cycle times up to 15 per minute (up to 15 cases per minute – speeds may increase depending on application).

U20 Pick & Place Uncaser

- 20 cycles per minute

- Round and non-round containers

- Medium to high production volume

CP20 – Pick & Place Case Packer The CP20 Pick & Place Case Packer allows for gentle packing of fragile product using a servo controlled two-axis overhead pick & place. It includes tooling featuring gripper, vacuum or bladder assemblies. Features single or double case infeed with cycle times up to 10 per minute (up to 20 cases per minute – speeds may increase depending on application).

CP20D-S Pick & Place Case Packer

- Pick & Place Packer

- 20+ Cases per Minute

- Round or Non-round Containers

- Medium to High Production Volume