Case Erector

Need a Better Way To Package Your Products?

Automatic Case Erectors Provide Continuous Improvement Solutions

Automatic case erectors help meet production needs. They reliably and consistently increase efficiency and build cases to enhance your end-of-line cost reduction solutions.

These are designed and engineered to meet high volume applications where they may often need to run 3-shift operations. Our fully-automatic case erectors can quickly erect and bottom-seal cases with either tape or hot melt adhesives.

We offer a number of different case erectos that allow customrs to erect all sizes of traditional RSC’s with speeds up to 30-35 cases per minute.

Automatic Case Erector Machine

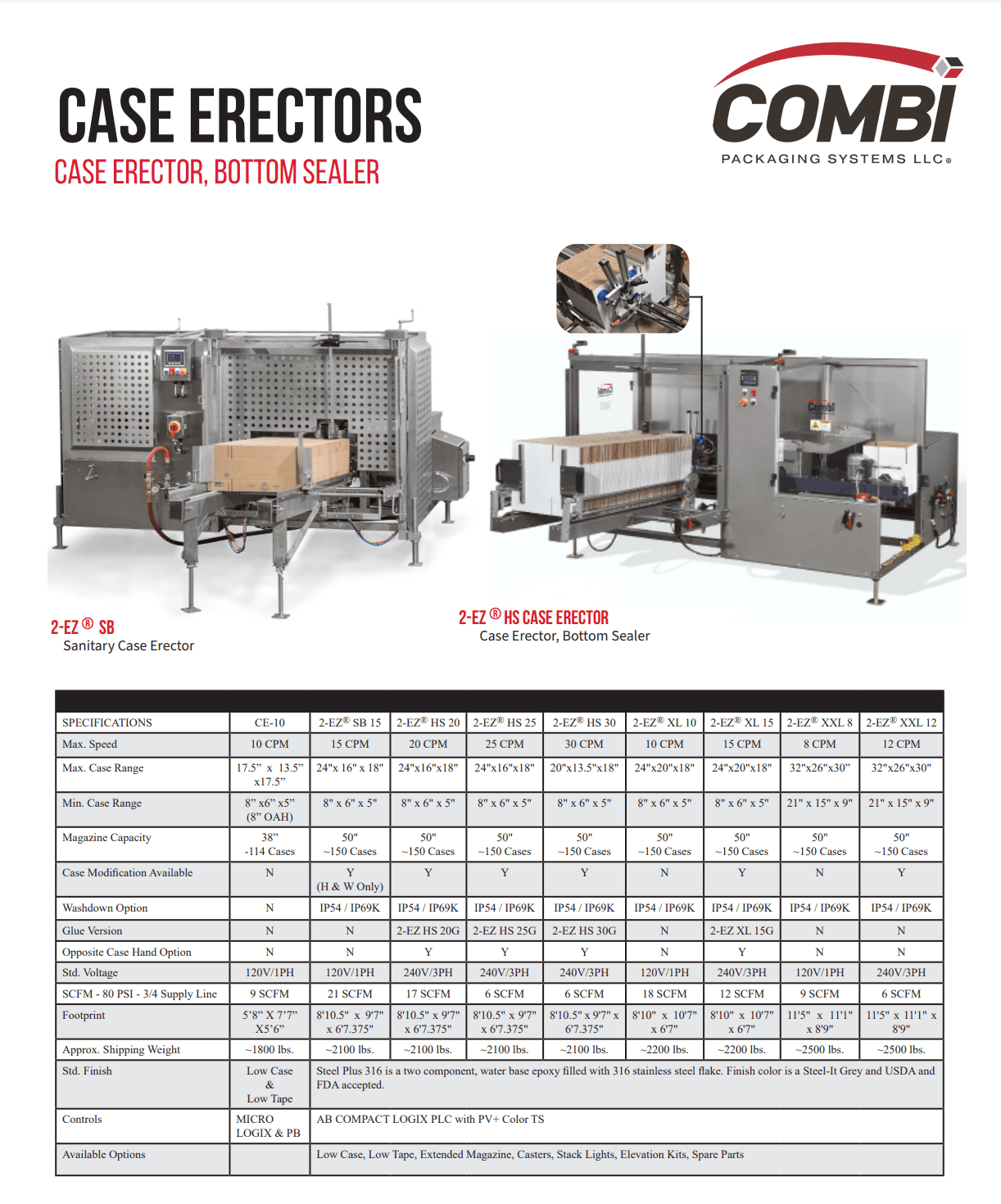

Combi Packaging Case Erector

Combi Packaging Case Erector

Combi automatic case erectors help meet production needs. They are designed to increase efficiency and consistently build cases for your end-of-line packaging machine needs.

2-EZ SB 15 & 2-EZ HS 30 Case Erectors are side belt driven (SB 15) and servo driven (SB 30) case erectors which form 2″ bottom tape seals up to 15 and 30 cpm. Combi’s EZ load walk-in powered case magazine and 3-minute “no tool” changeover system are standard features.

2-EZ XL Series Case Erectors is a no compromise case erector solution which forms bottom seals for large cases. These are designed with heavy duty components, a positive case opening system, and transfer Belt Driven or Servo Driven carriage assemblies. While case speeds are size dependent, our case per minute erector range is from 8-15 containers per minute.

EZ SB RTE Sanitary Washdown Case Erectors is a stainless steel washdown and automatic case erector design. It utilizes a bottom sealer that virtually reduces and/or eliminates potential areas where undesirable bacteria might gather.

2-EZ G / 2-EZ HS G Hot Melt Case Erectors are a hot melt case erector that will erect corrugated cases and close the bottom flaps with glue. These machines are equipped with the dependable, industry leading Nordson Pro Blue Liberty Hot Melt System. The system creates a strong, rigid bond that helps that boxes remain intact and contents remain secure at all times.

RCE Case Erectors – Random Case Erectors are combined with a FANUC M-10iD/12, six-axis robot with multiple case magazines and a bottom flap folder with an integrated 3M tape head for random box erecting . This system allows you to erect multiple cases, without the need for multiple erectors, the floor space they consume and costly changeover downtime.

Series Case Erectors are designed to be all essentially the same machine, but in different size frames. This modular approach allows us to integrate any size case erector with any case loader, be it an ErgoPack, Drop Packer, Horizontal Loader, or Servo Pick & Place Packers creating custom case erectors.

Hamrick Packaging Case Erector

Hamrick Packaging Case Erector

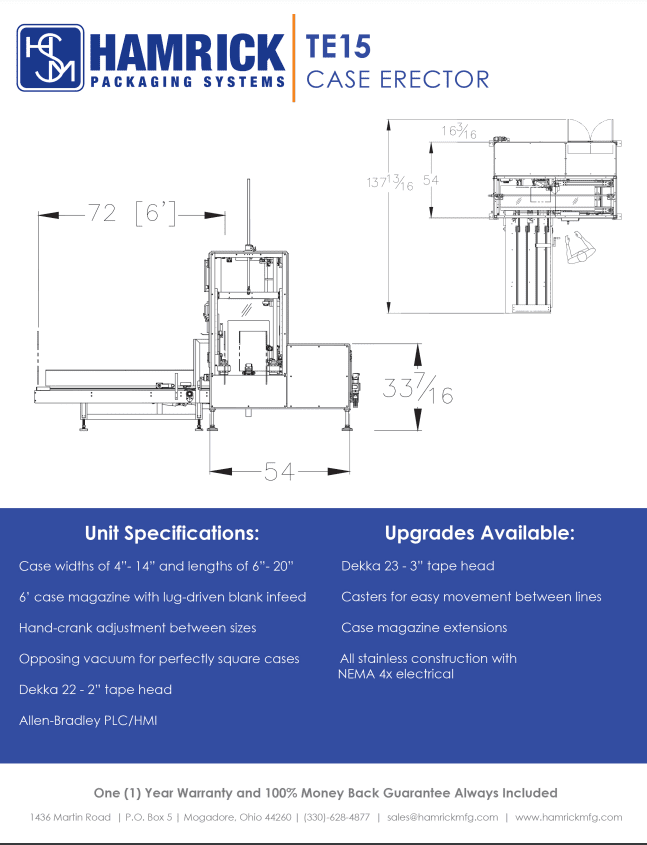

TE15/20 Case Erector is designed to erect cartons with a width range of 4″ – 14″ and a length range of 6″ – 20″. We provide a 6′ case magazine with a lug-driven blank infeed and a hand-crank adjustment between sizes. To achieve perfectly square boxes we include opposing vacuum to accomplish this critical task. Controls platform is an Allen-Bradley PLC/HMI along with a Dekka 22 – 2″ tape head with an optional Deka 23 – 3″ tape head.

The following options are available to help assist with varying production requirements such as, casters for easy movement between lines, case magazine extensions, and an all stainless construction with a Nema 4x electrical package.