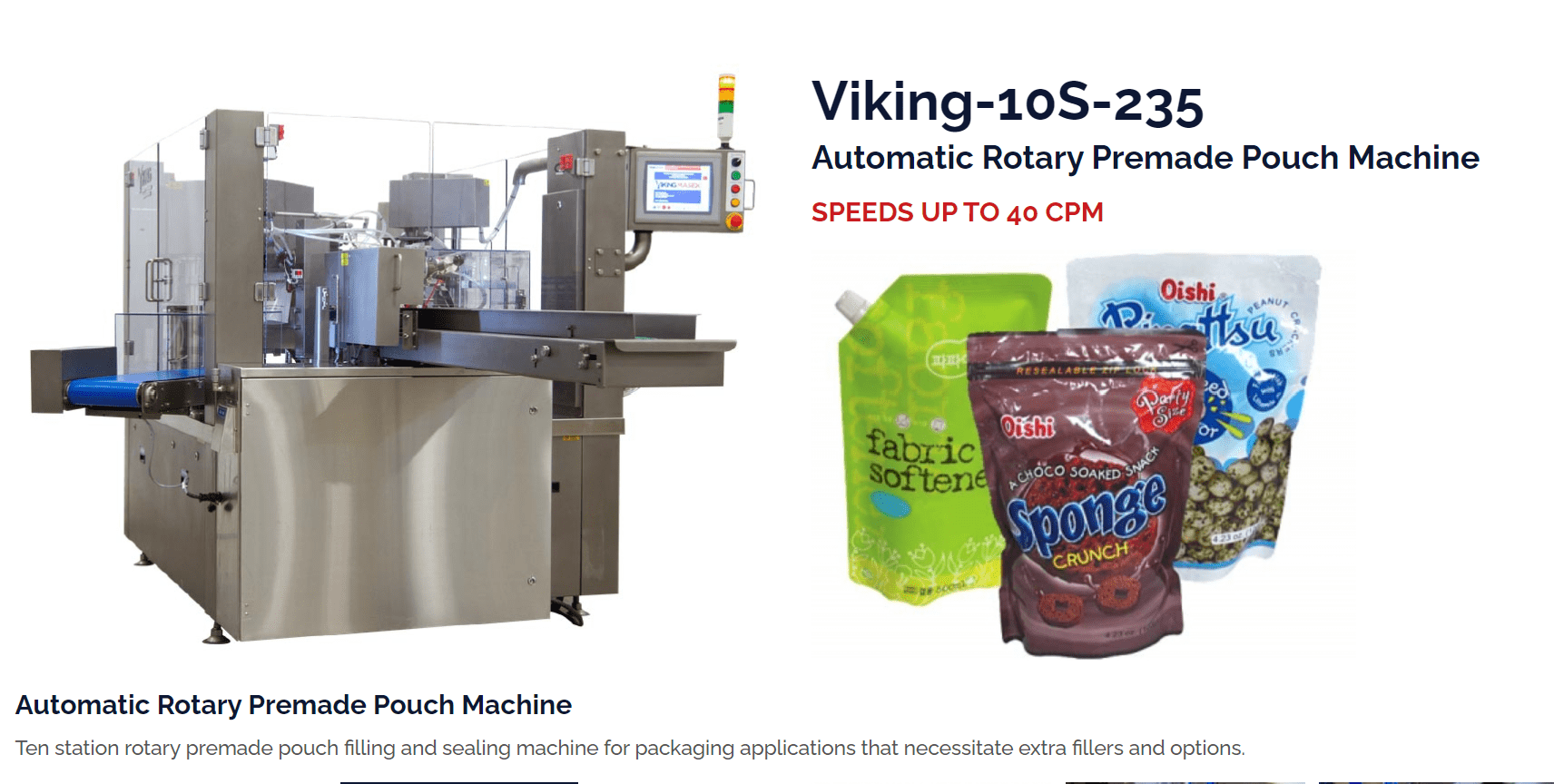

Premade Pouch / Bag /

Spout / Stand Cap Packaging Machines

A Rotary Premade Pouch Packing Machine

Makes Your Packaged Product Look Modern

Our automatic premade pouch packing machine will fill and seal already premade custom pouches, so no rollstock is required. Doing so can increase output by as much as 50 percent with our rotary premade pouch machine.

We offer single-lane models with either six or eight stations, dual-lanes with eight stations, or four-lane with six to eight stations. Whatever your output requirements are, we have a solution for you. We offer easy integration with volumetric, multi-head weighers, auger, liquid pump, cup fillers as well as infeed and outfeed conveying equipment.

These rotary pouch filler systems can package anything from coffee to snacks to legal cannabis products. These flexible packaging machines are a top choice for complete premade pouch packaging solutions.

Premade Pouch Filling Machine

Premade Pouch

Viking Masek Automatic Premade Pouch Filling Machine

Streamline your operations and increase output by as much as 50% with our automated rotary premade pouch machines. Unlike our vertical form fill and seal machinery that utilizes roll stock film to create bags, our premade pouch packing machines offer something completely different.

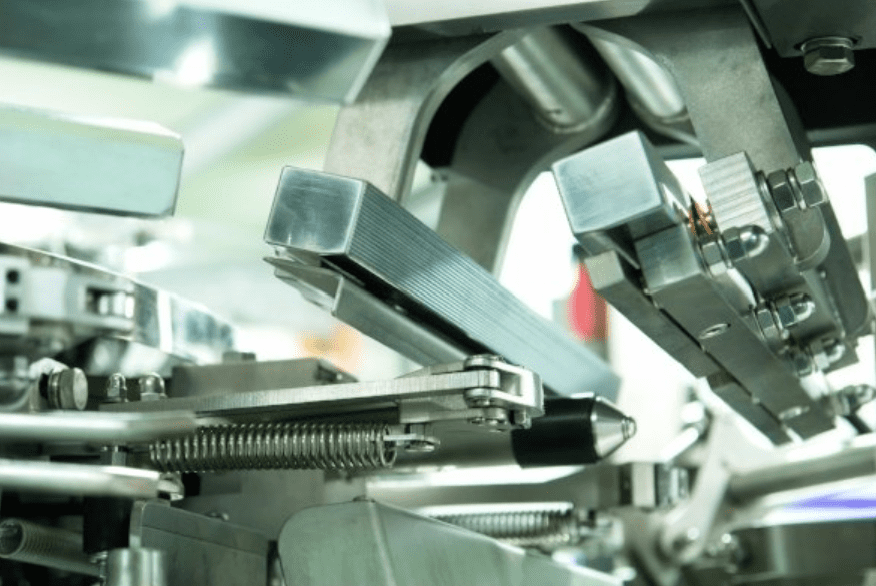

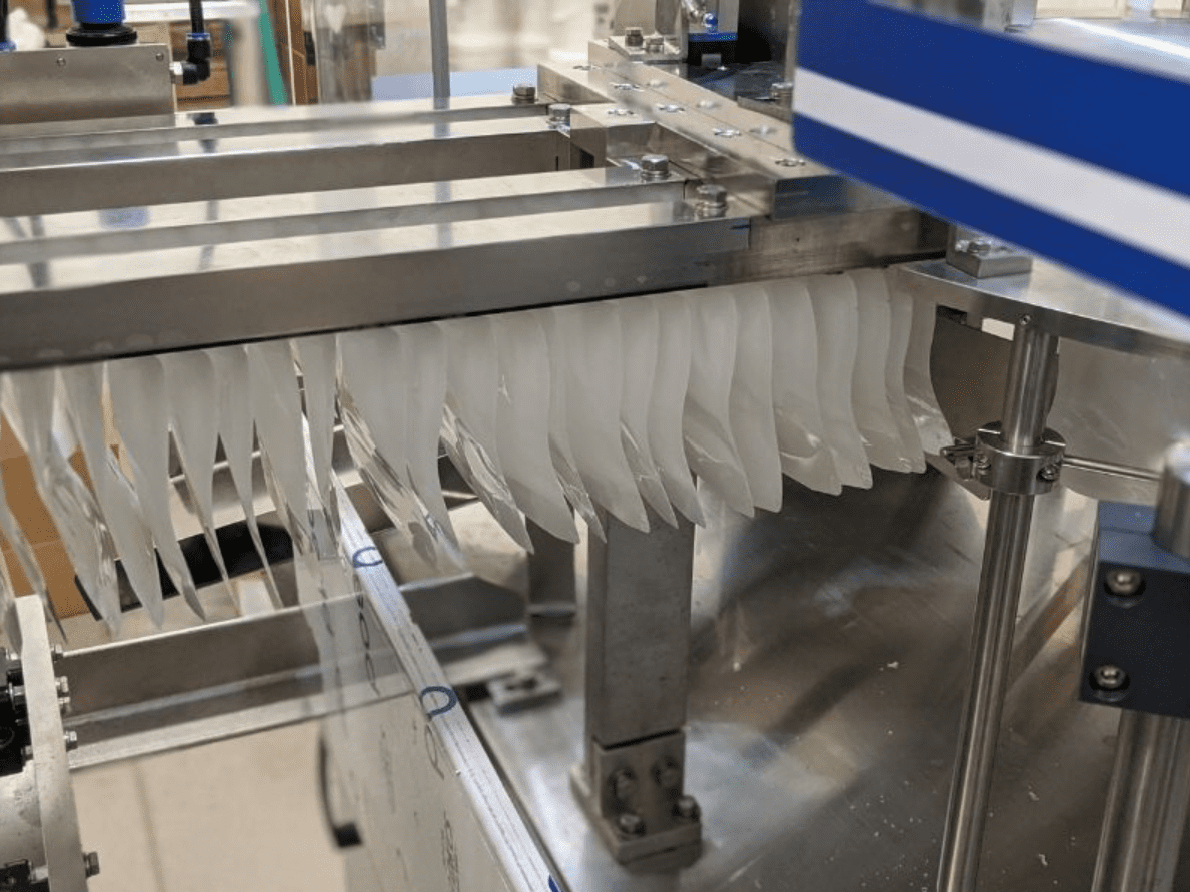

These innovative packaging machines fill and seal already premade custom pouches, so no roll stock is required. The end result – your package product looks modern. offers convenience, and differentiates yourself from your competition. Our rotary premade pouch packaging machine are incredibly easy to learn and operate, package anything from liquids, to pet foods, to powders, to legal cannabis products. Easy integration with scales, infeed and outfeed conveying equipment, cartons, rapid sealing, the latest Allen Bradley components and servo drives, and durable stainless steel construction.

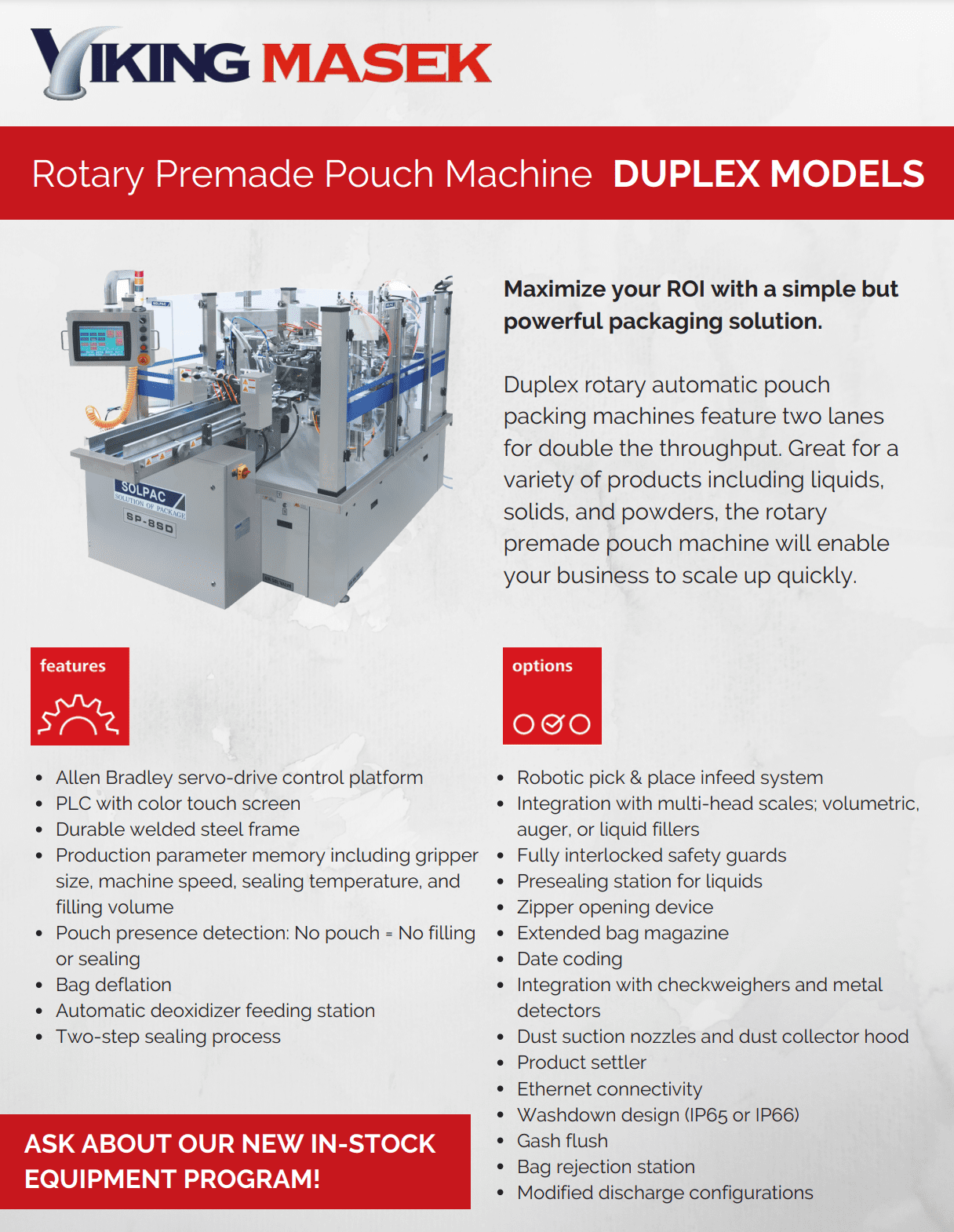

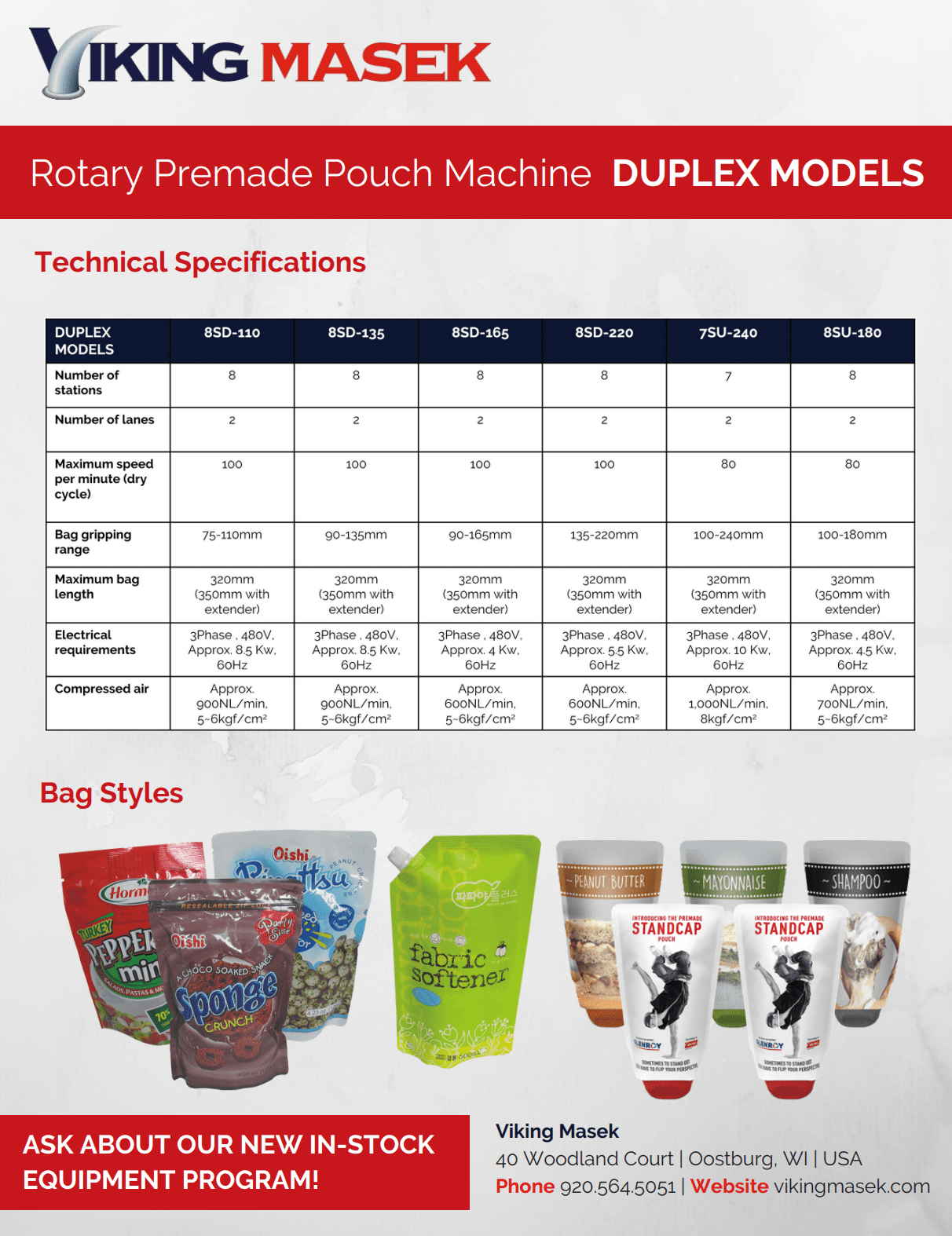

We offer 3 models:

Simplex: A premade pouch packing machine fills and seal custom premade pouches one at a time, at speeds up to 60 cycles per minute.

Duplex: A premade pouch packing machine fills and seal custom premade pouches two at a time, at speeds up to 120 cycles per minute.

Quadruplex: A premade pouch packing machine fills and seal custom premade pouches up to four at a time, at speeds up to 200 cycles per minute.

Spout Pouch

Viking Masek Automatic Rotary Premade Center Spout Pouch Packing Machine

Viking’s two-lane automatic center spout pouch filling and capping machines provide exceptional efficiency gains for the packaging of liquid products. Accommodating the latest in convenience spouted pouches, this packaging machine will help you increase throughput and cut costs. Modular build with a touchscreen HMI, the spout machine is easy to maintain and simple to control, requiring only one operator.

We include features such as a PLC control with touch screen operation, servo-driven Bradley control platform, a highly durable stainless steel frame, pouch presence detection – no filling, no sealing, cartridge rail type loading, liquids filling, cap feeding and placing and with automatic capping. We can achieve up to 80 pouches per minute with accuracy and reliability. Pouch size ranges with a variable minimum and a maximum of 100mm (W) x 170 mm (L).

Standcap Pouch

The newest premade pouch solution, the Standcap Pouch, is revolutionizing premade pouch packaging. This inverted wedge-shaped pouch style features a distinctive flip-top cap that serves as the base for the finished package.

Automatically fill and cap Standcap Pouches of liquids or dry products like baby food, condiments, personal care, etc. Designed to be a modular build with a touch screen HMI and servo-driven Allen Bradley control platform. This spout machine is easy to maintain and simple to control, requiring only one operator.

The premade Standcap Pouch packaging machine features a Single or Dual station configuration, highly durable stainless steel frame, production parameter memory including gripper size, machine speed, sealing temperature, filling volume and a cooling station for liquids products . In addition, pouch presence detection – no filling / no sealing, bag deflation with wire guide or push bars, an automatic deoxidizer feeding station and a two step sealing process guarantees clean sealing.