Rigid Packaging

Packaging Machines

The Packaging You Choose for Your Products is Crucial

No Matter Where Your Business is Positioned in Industry

Whether you’re looking for the first time or looking to upgrade exisitng packaging machines or production lines, we have extensive experience to fill a wide range of materials and products. Our machinery is designed to be durable, with ease of operation, quick changeover, sanitation and maintenance.

We specialize in packaging powder, granular, pariculate solids, frozen foods, liquids from flowable to viscous – hot or cold fills, in both food and non-food industries. We offer packaging machine configurations from semi to fully automatic, inline to high-speed rotary, and more.

Our repeat customers continually seek us to explore timely and budget friendly solutions to their market challengs. Challenges like: production efficiencies, costly waste reduction, innovation with packaging styles, improve product and package quallty.

Rigid Containers

Styles:

Bottle, Bowl, Can, Carton, Container, Cup, Jars, Totes, Tray, Tub.

Materials:

Plastic, Glass, Metal, Aluminum, Paper, Flexible Film.

Industry:

Food & Non-Food

Markets:

Retail, Institutional, & Commercial.

What is Rigid Packaging?

Rigid Packaging refers to the strong and durable materials used to contain various products. This includes a range of packaging designed to avoid bending, curving, snapping, or breaking – such as cardboard, glass, metal, and hard plastics.

This type of packaging is typically used with fragile products or those that need to maintain their integrity without being manipulated or directly handled. Rigid containers include cardboard cereal boxes, glass condiment jars, metal cans, and plastic water bottles.

Rigid Packaging Machines

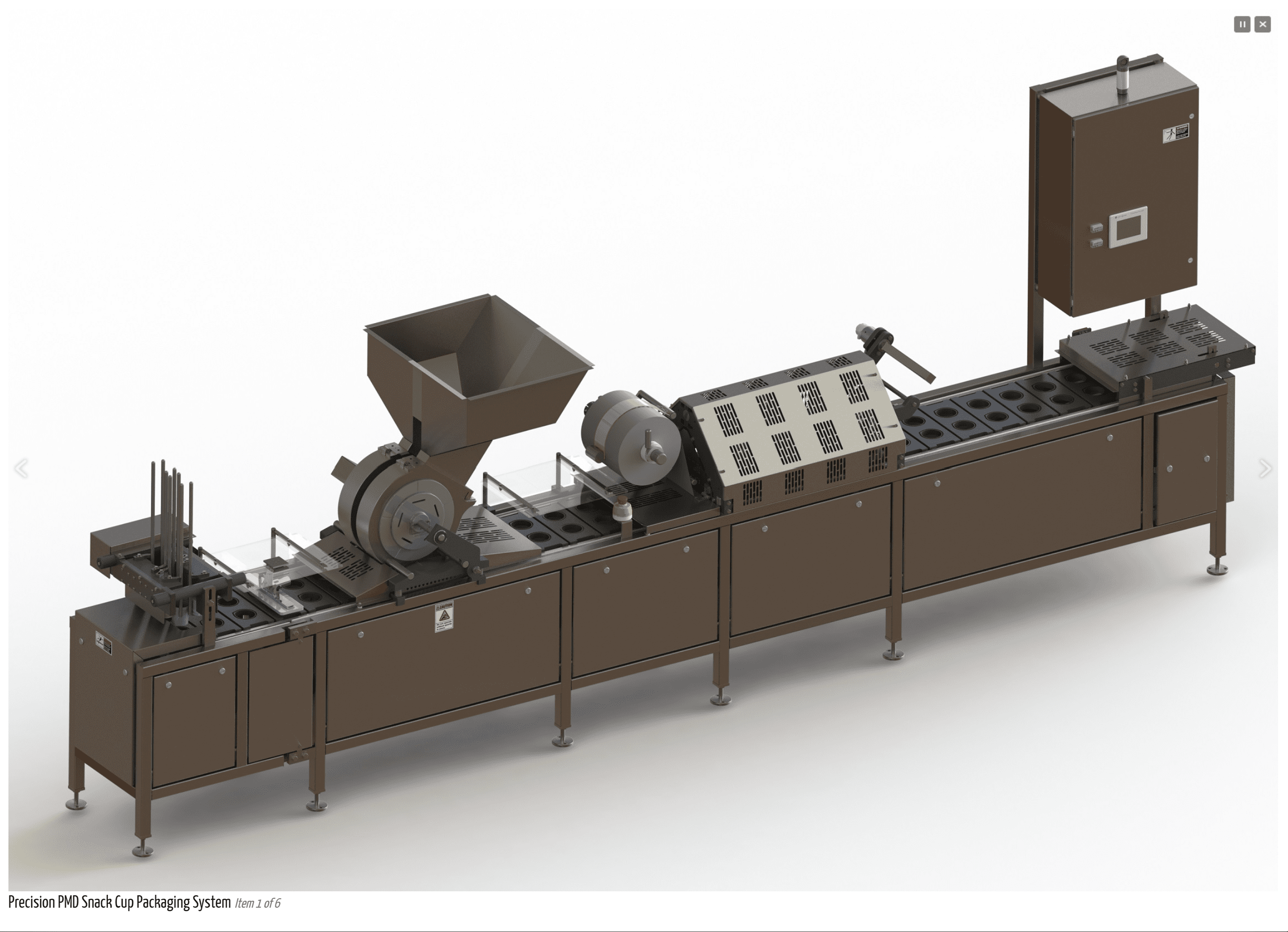

Cup Packaging

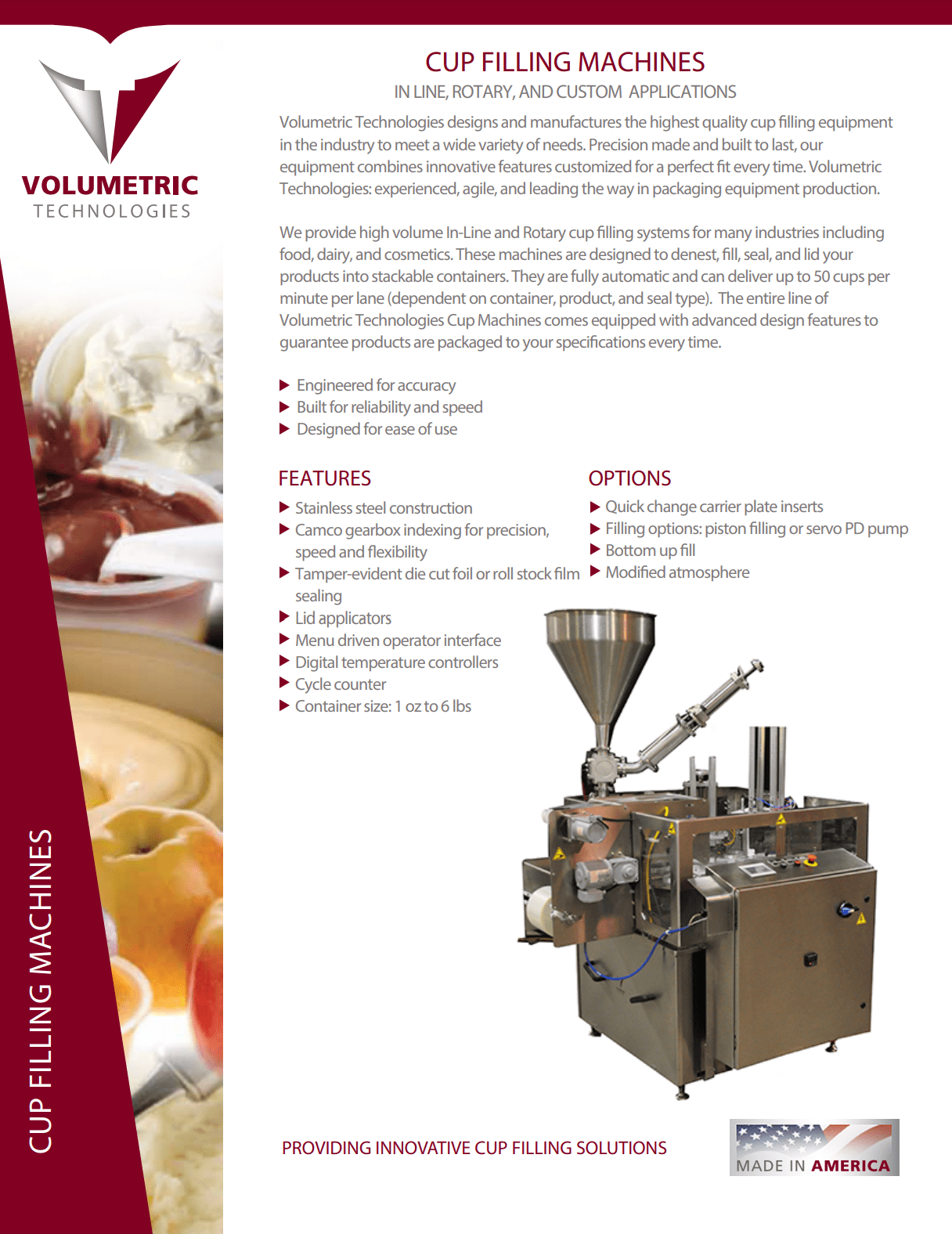

Volumetric Technologies Automatic Cup Filling and Sealing Machine

We provide high volume Rotary Cup Machines for many industries including food, dairy, and cosmetics. These packaging machines are designed to de-nest, fill, seal, lid, and eject your products. Our Rotary Cup Machines are fully automatic and can deliver food products up to 40 cups per lane, per minute, with configurations up to 3 lanes, and with cup sizes ranging from 1- 16 ounces.

The entire line of Volumetric Technologies cup machines comes equipped with advanced design features to guarantee products are packaged to your specifications every time. They are equipped with a solid state PLC and a touchscreen HMI gives flexibility to configure the equipment properly for your application. All control functions are adjustable via menus-driven operator interface.

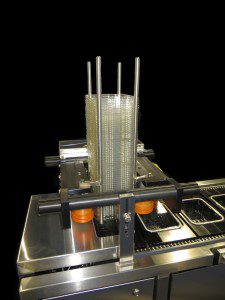

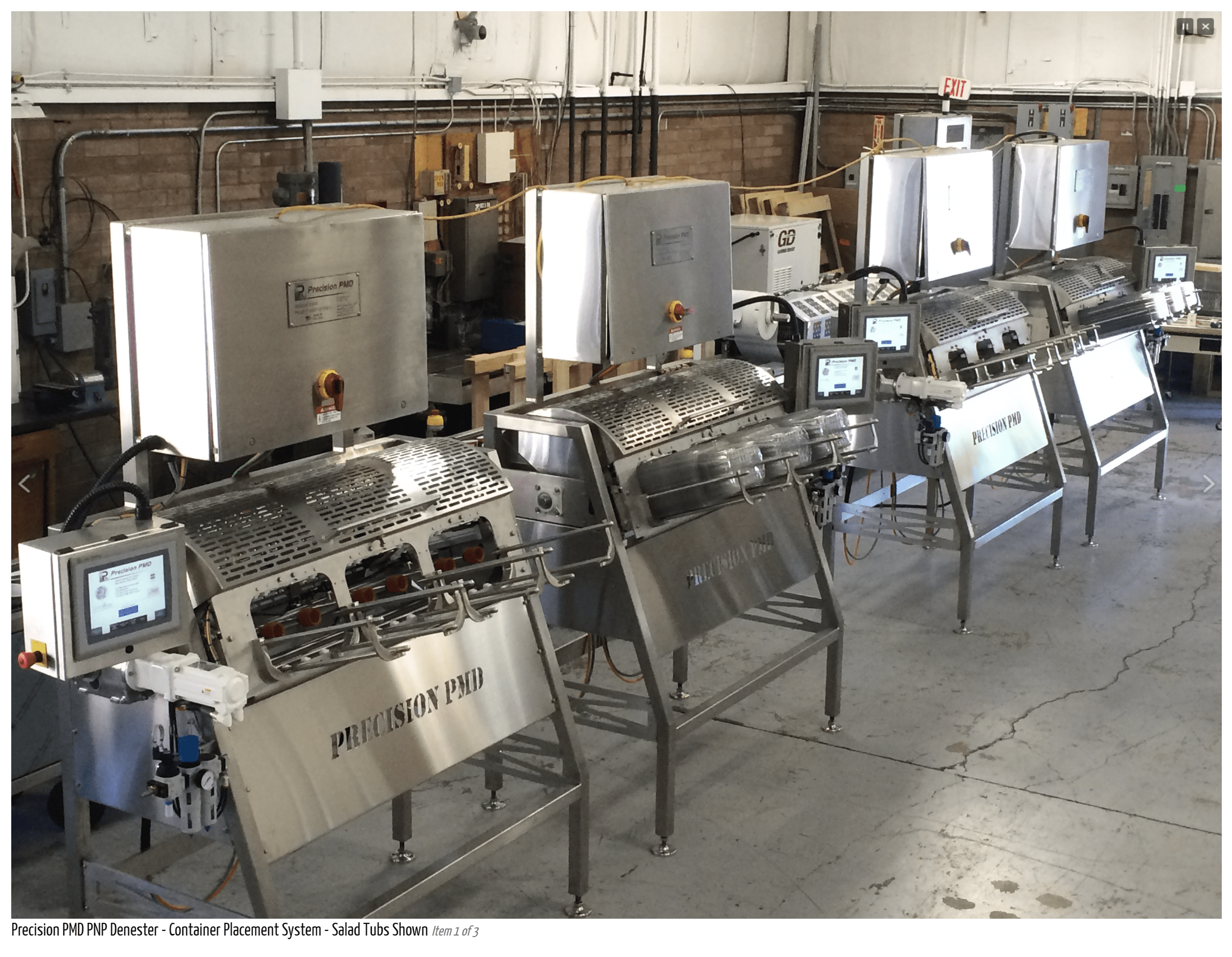

Denester

Precision PMD Denester Machines

We provide high volume Rotary Cup Machines for many industries including food, dairy, and cosmetics. These packaging machines are designed to de-nest, fill, seal, lid, and eject your products. Our Rotary Cup Machines are fully automatic and can deliver food products up to 40 cups per lane, per minute, with configurations up to 3 lanes, and with cup sizes ranging from 1- 16 ounces.

All Denesters can be servo-driven, or can be mechanically linked to your existing systems drive source. They can mounted on a mobile frame or can be mounted directly to your existing system. We can provide an optional container feeder system that allow an operator to load multiple stacks into the Denester which will free that person up to assist with other tasks.

We offer 3 Models:

RC Series Denesters are designed for single serve cups to foodservice pans with continuous to intermittent motion models. You can easily change container sizes without measuring and without acme thread adjustments. We include AB Servo & Controls with speed ranging up to 200 containers per minute.

PT Series Denesters are designed for use with formed paperboard trays with either continuous or intermittent motion models. Paperboard Tray sizes range from 3″ x 3″ to 10″ x12″ with speeds ranging up to 160 trays per minute.

PNP Series Denesters are ideal for de-nesting tubs and lids that are less rigid or do not have uniform stacking features. PNP Denesters can be mounted over existing machines or as a new line system.

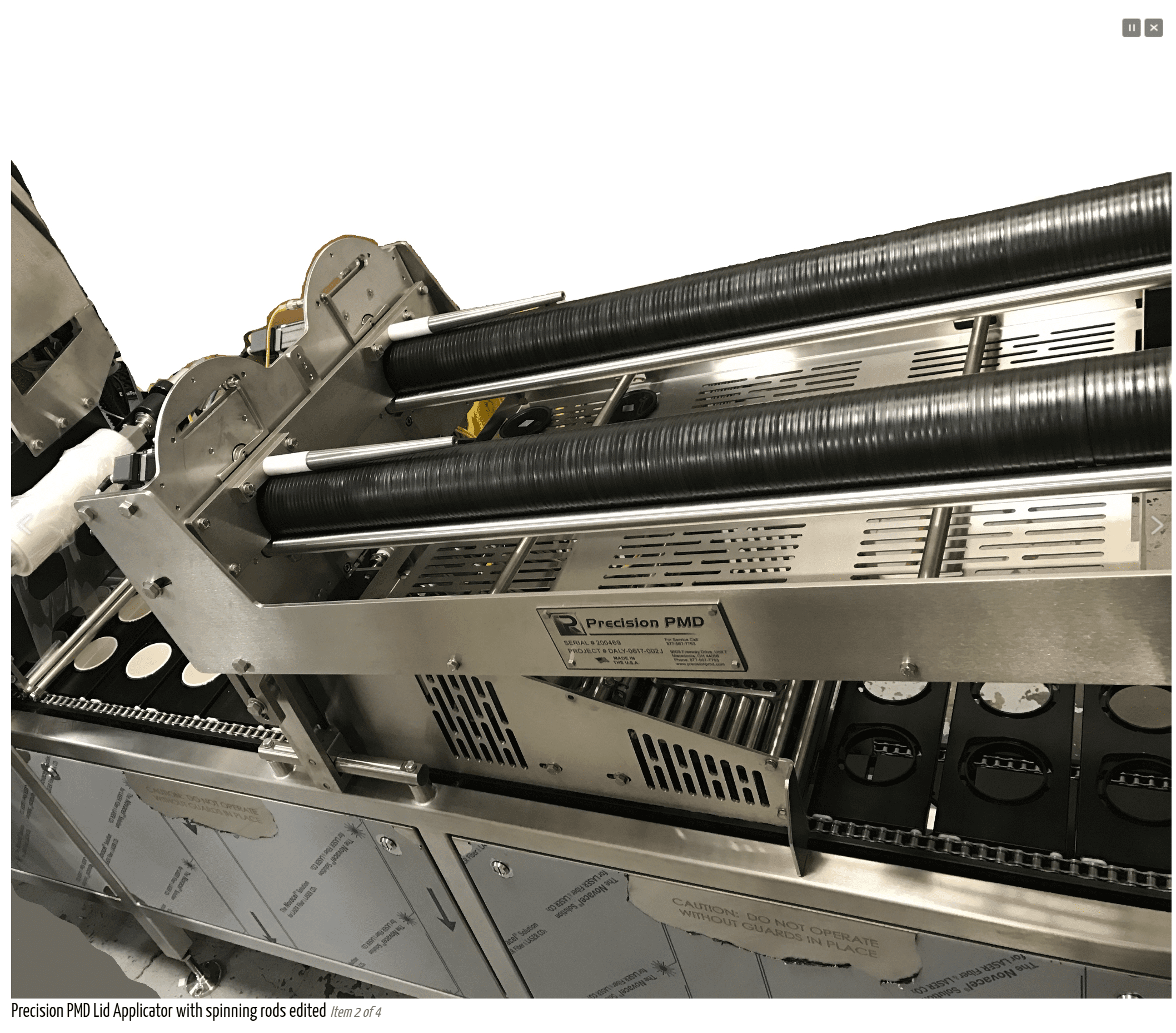

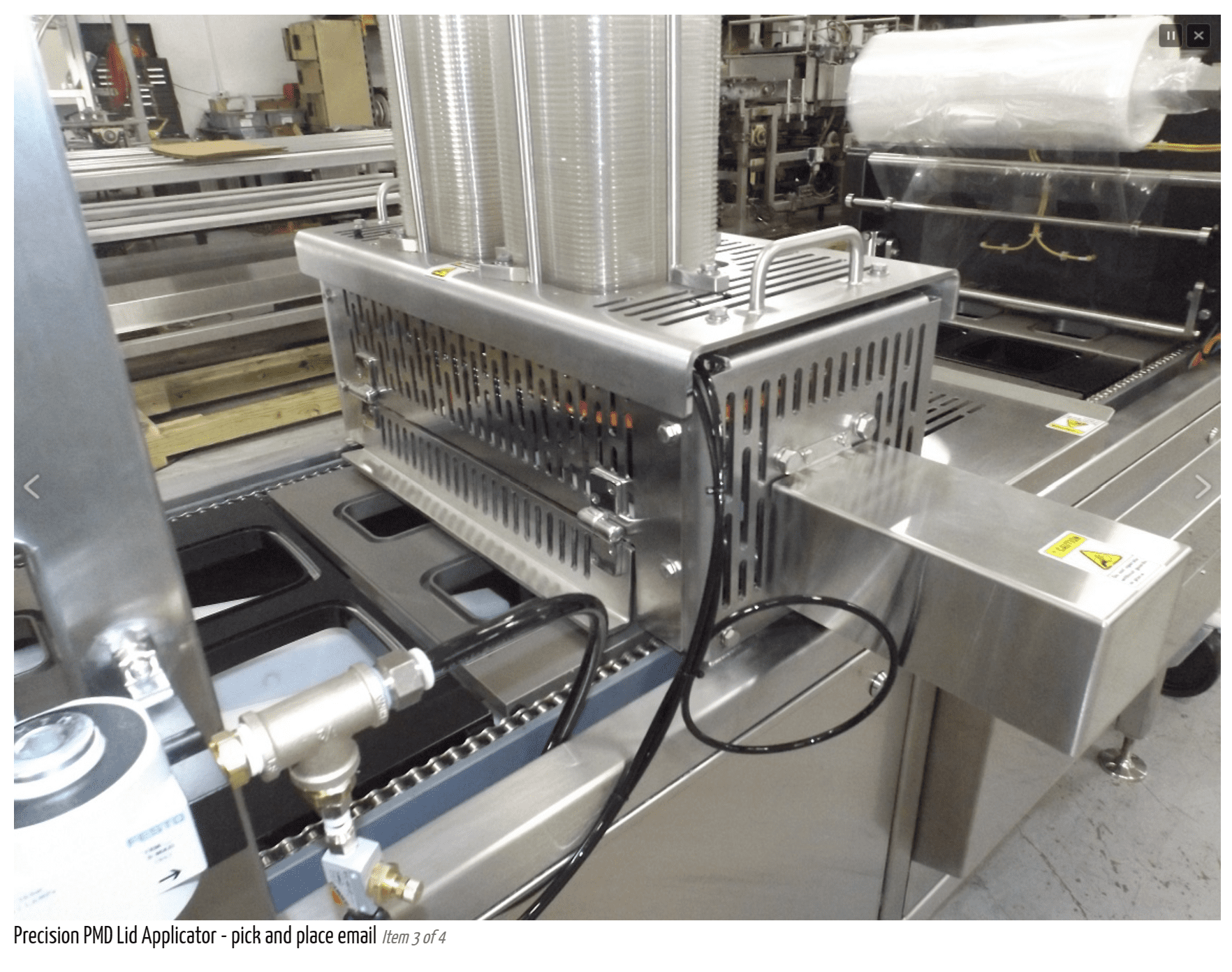

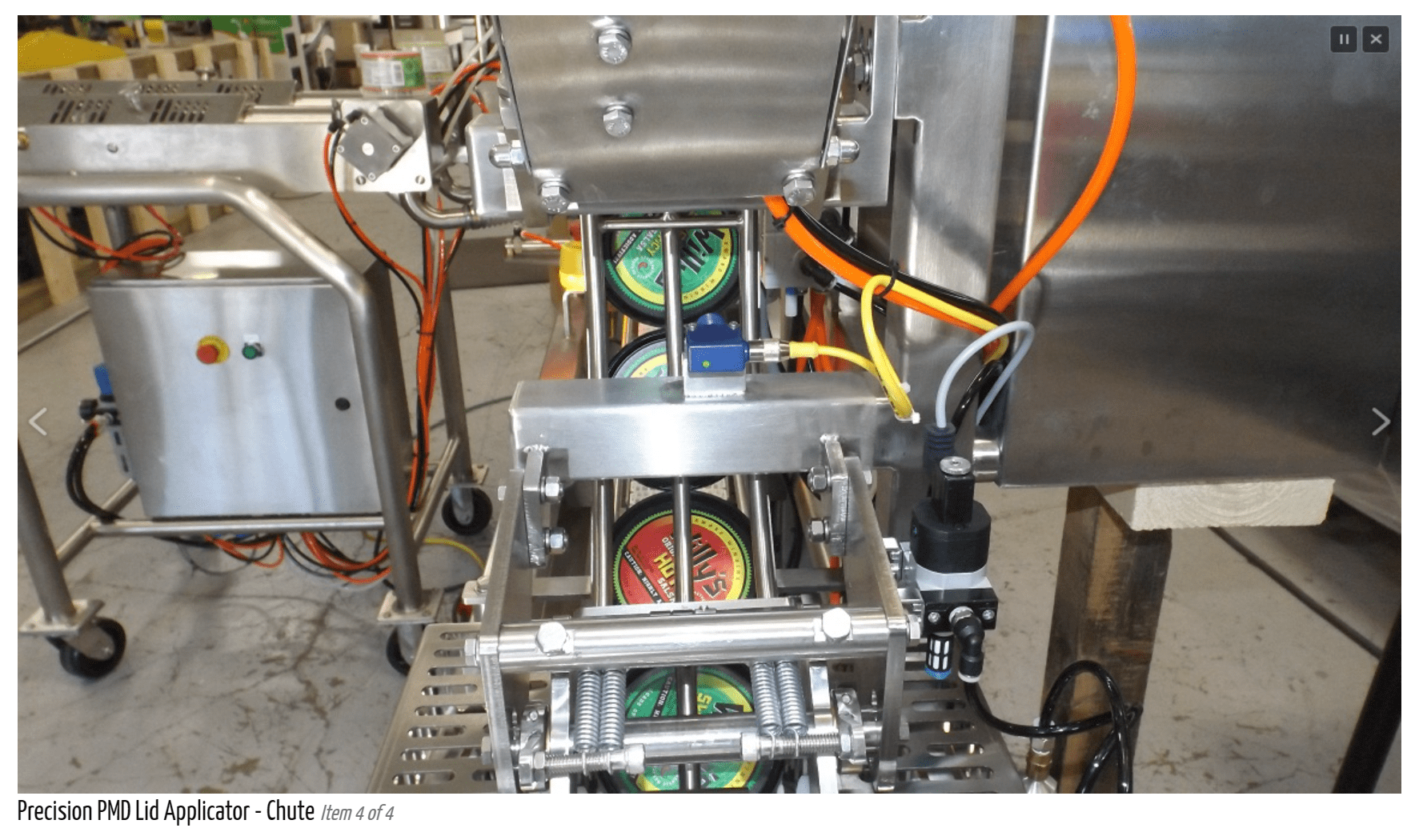

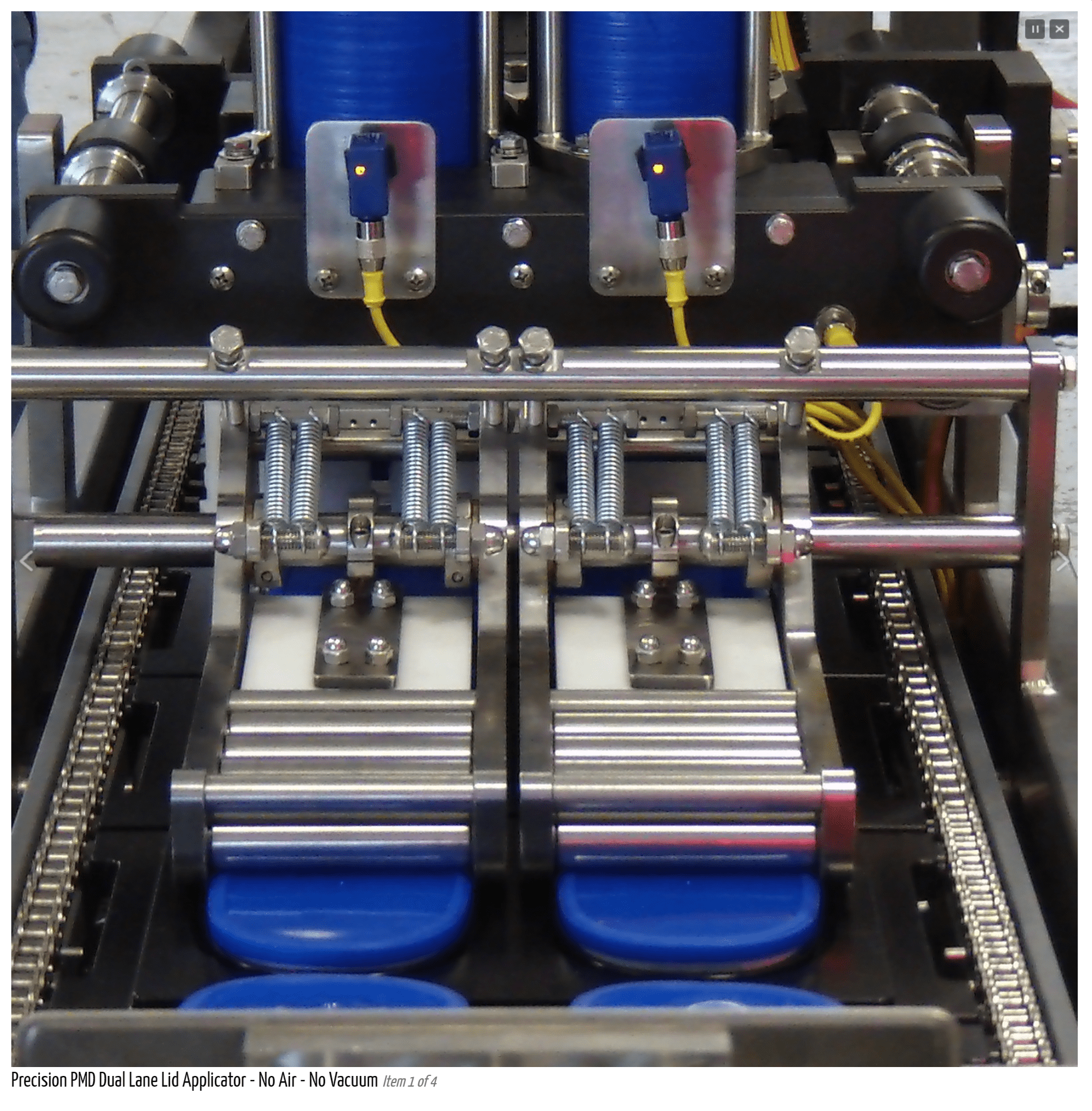

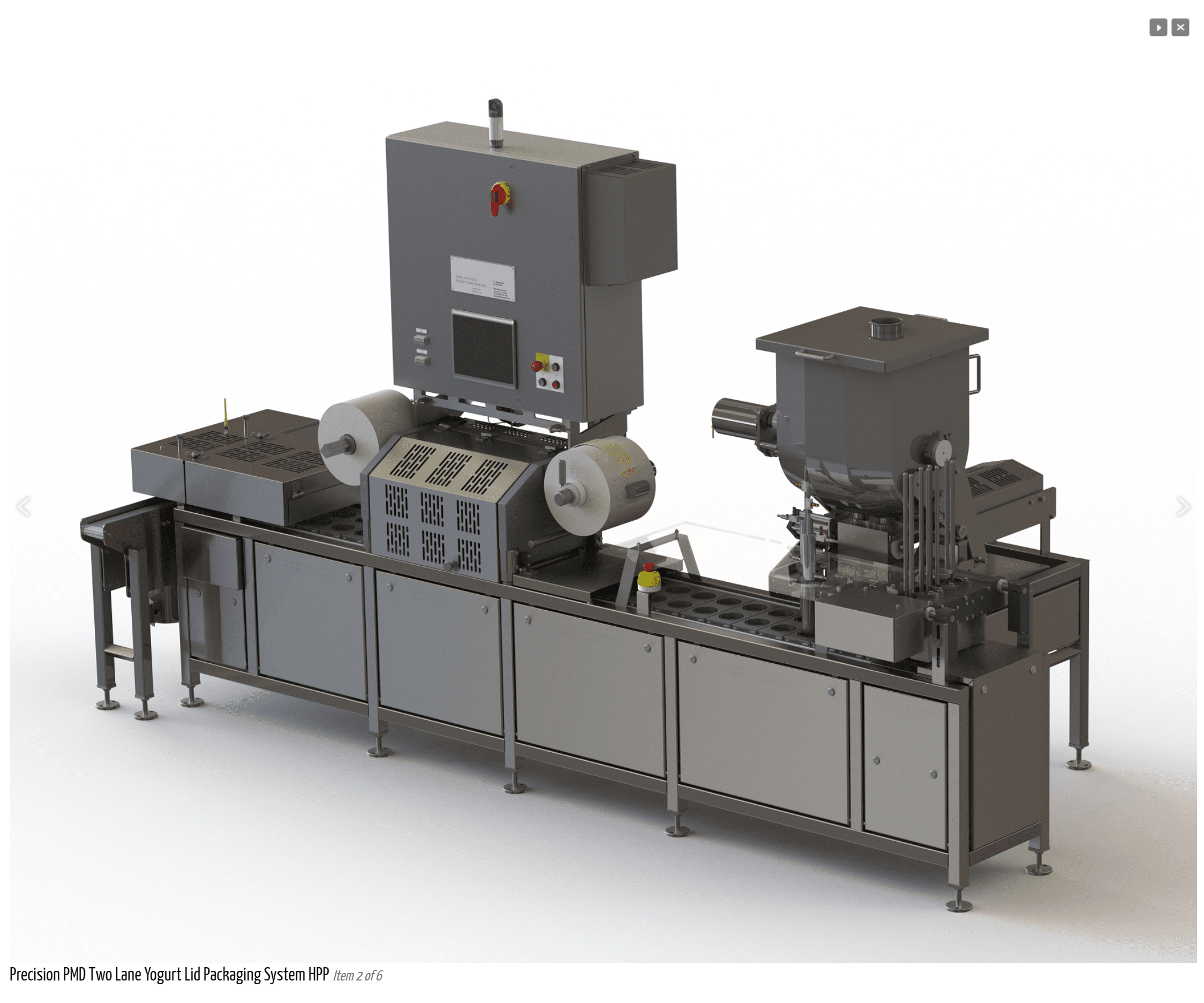

Lid Applicator

Precision PMD Rigid Packaging Machine Lid Applicator Machine

Precision PMD Lid Applicators are an integral part of de-nesting, filling, and sealing systems. Our unique approach to lid applicators result in a compact servo-driven applicator that that takes up a minimal amount of line space for a fraction of what a standalone lid applicator would sell for.

We offer optional items to include servo control, automatic loaders for multiple stacks of lids, no container/no lid, a portable, stand alone frame for mobility, single and multiple lanes, and spinning rods.

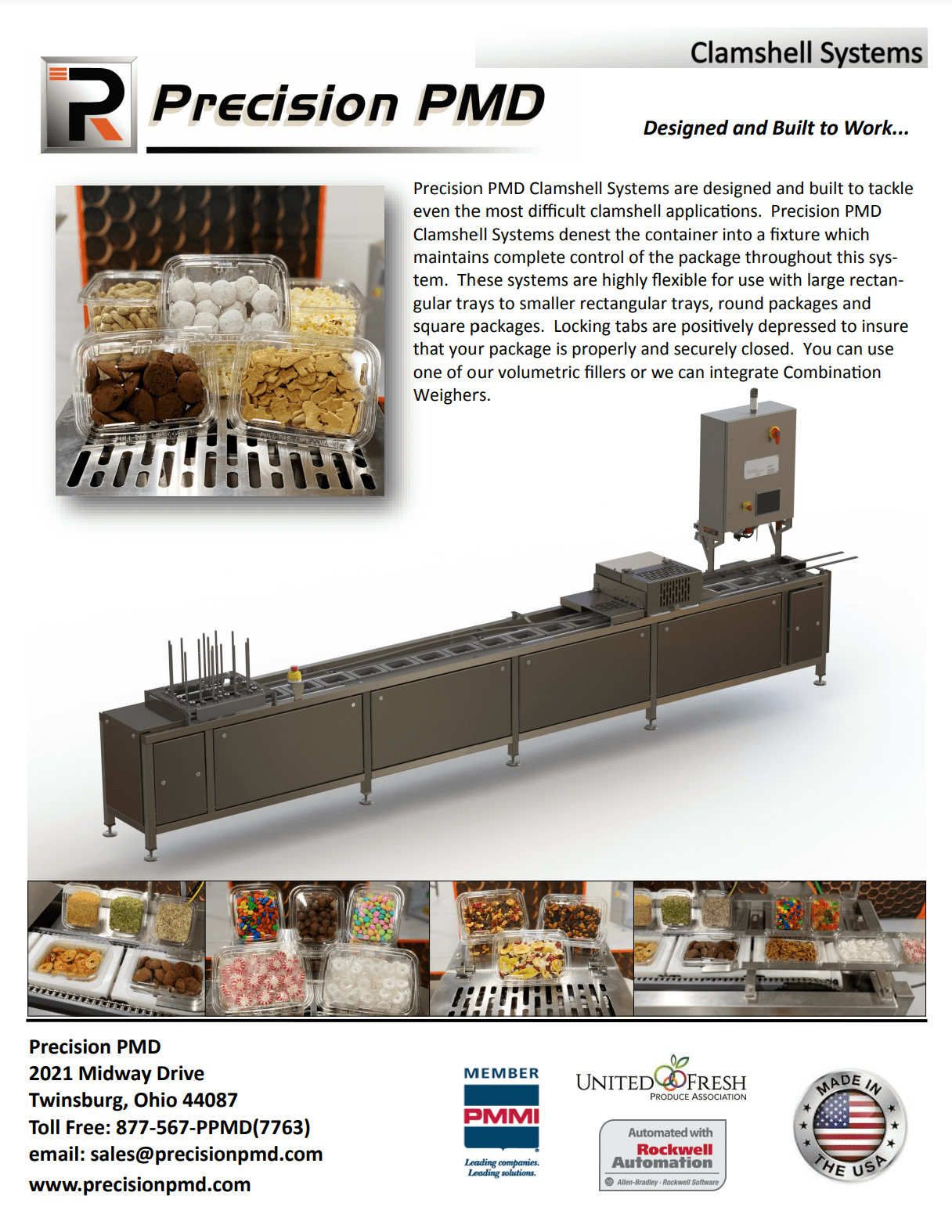

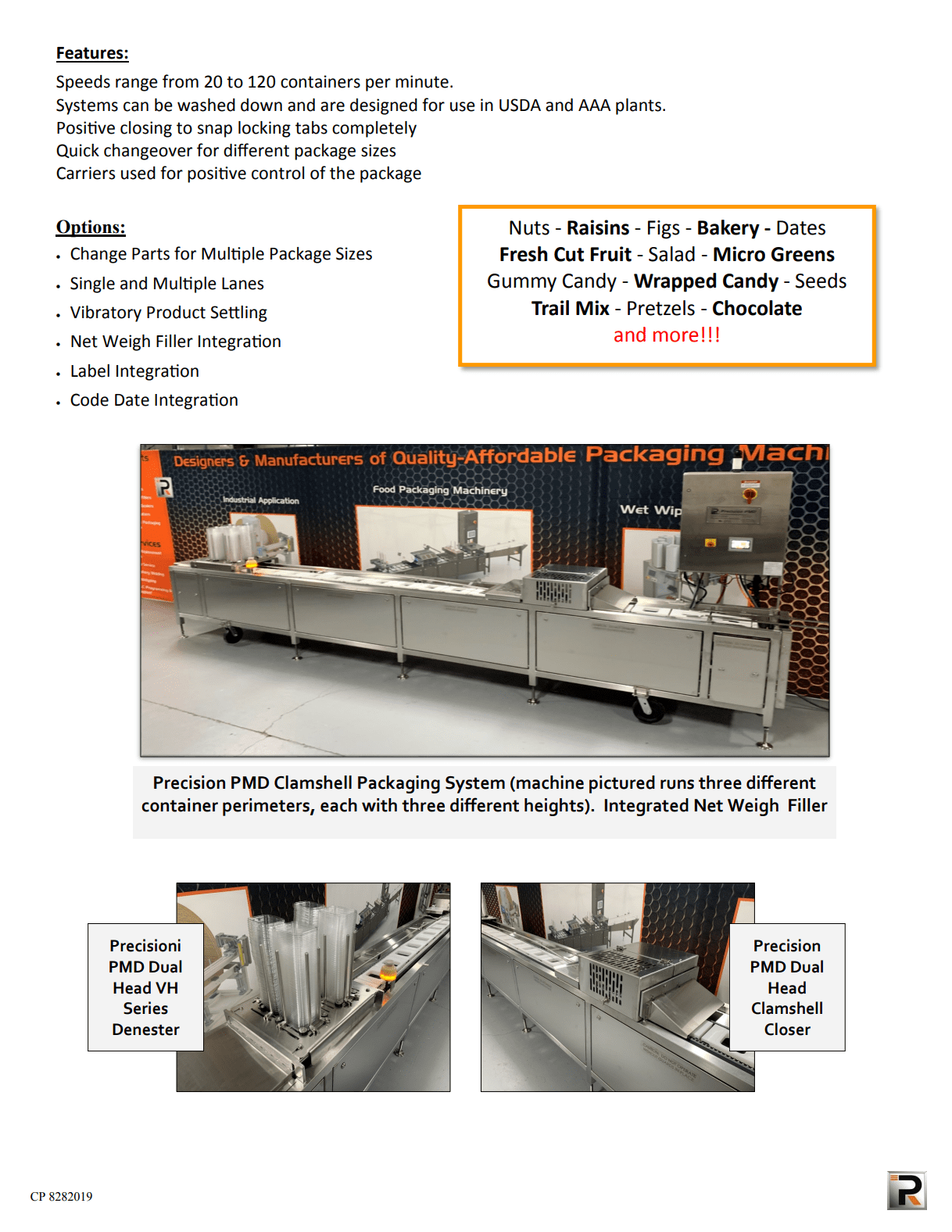

Clamshell Containers

Precision PMD Food Packaging

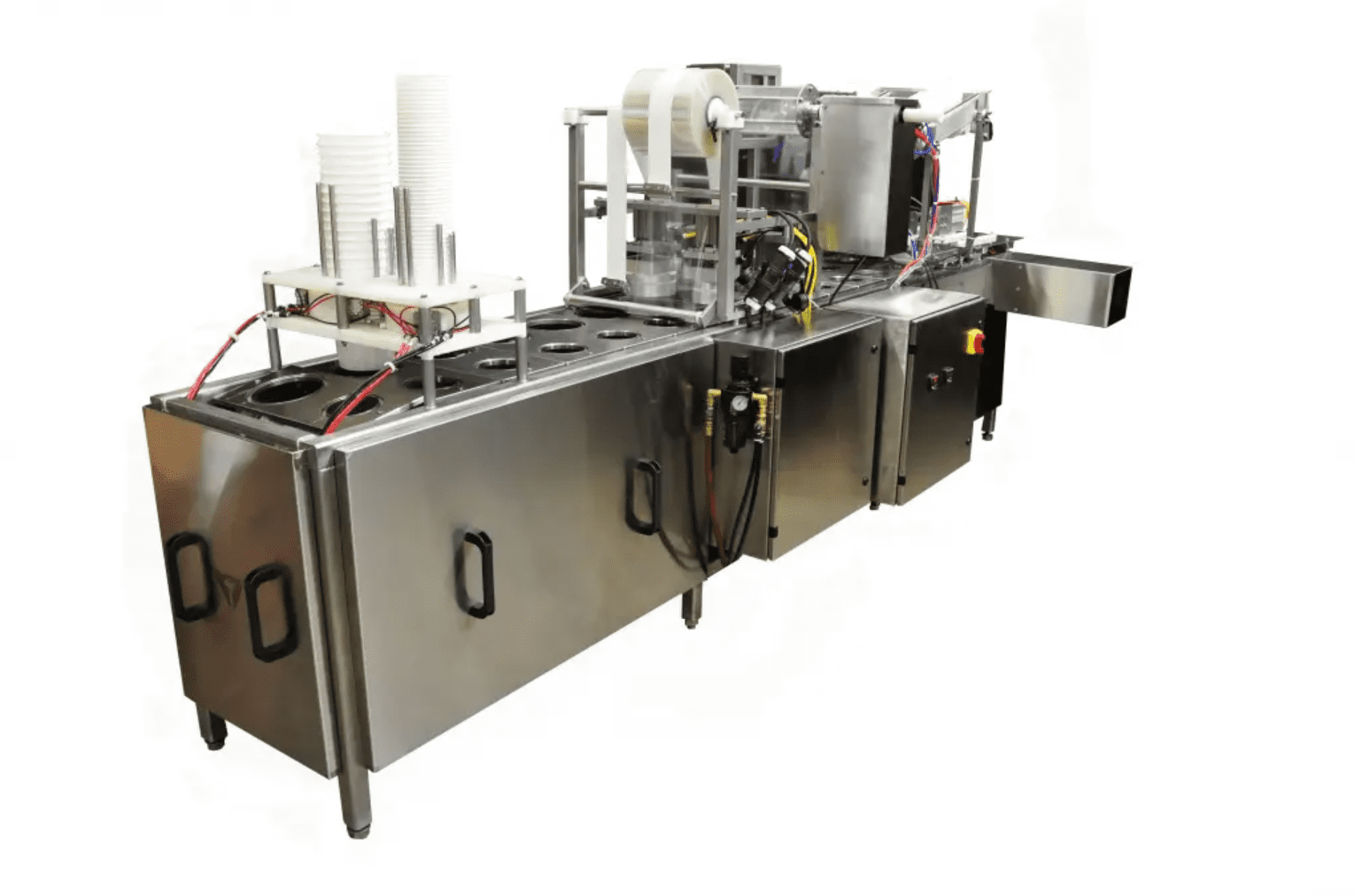

Plastic Clamshell Containers

The clamshell packaging machine is ideal for nuts, dried fruits, snack mixes, bakery goods, cookies, popcorn, seeds, pretzels and other food. We can fill a variety of multiple container styles automatically and designed to your specific application.

The Clamshell packaging machine displayed on Page 2 of the brochure here is a Two Head VH Series Denester with a Two Head Clamshell Closer and Integrated Net Weight Scale Filler (not shown) running at 50 containers per minute.

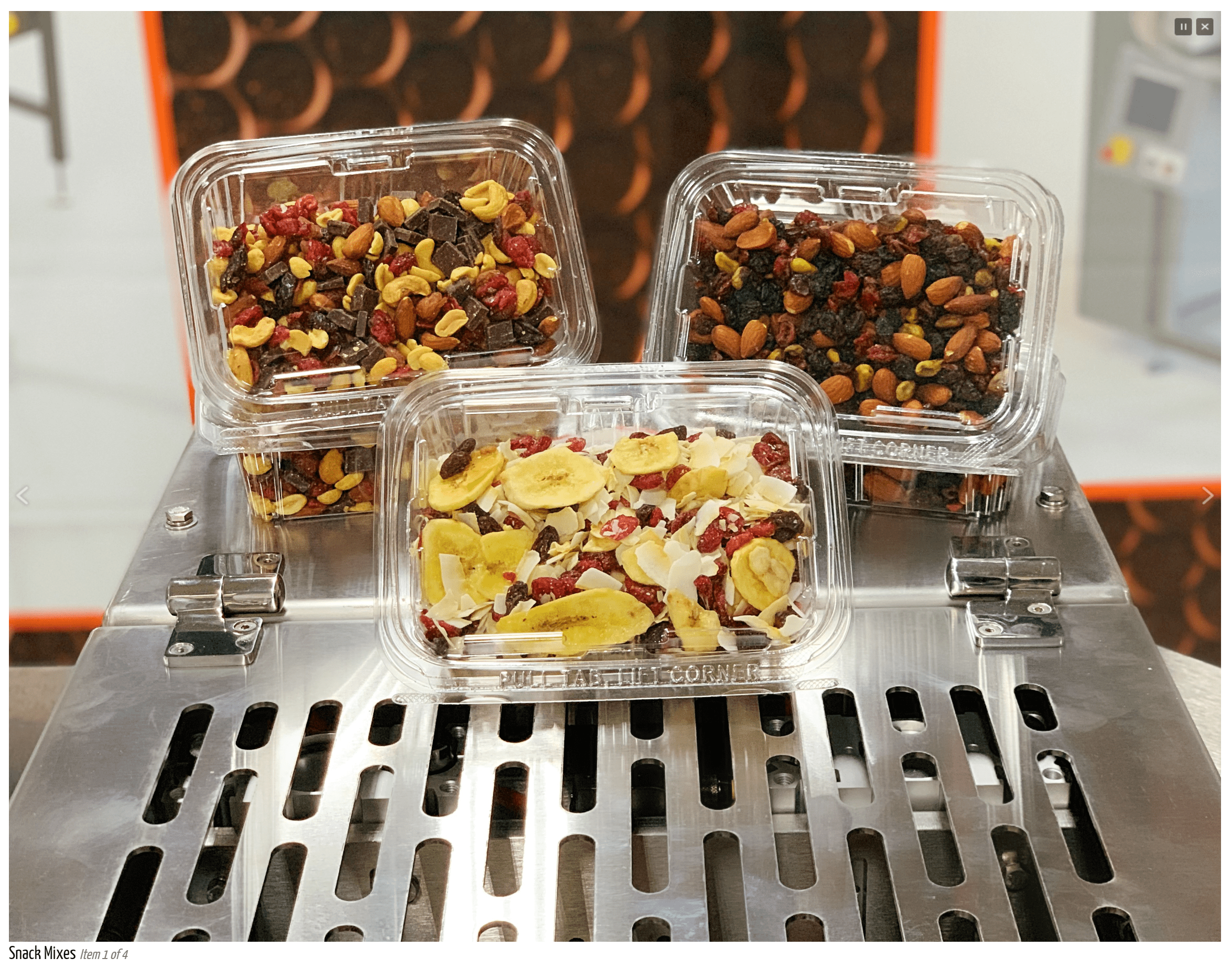

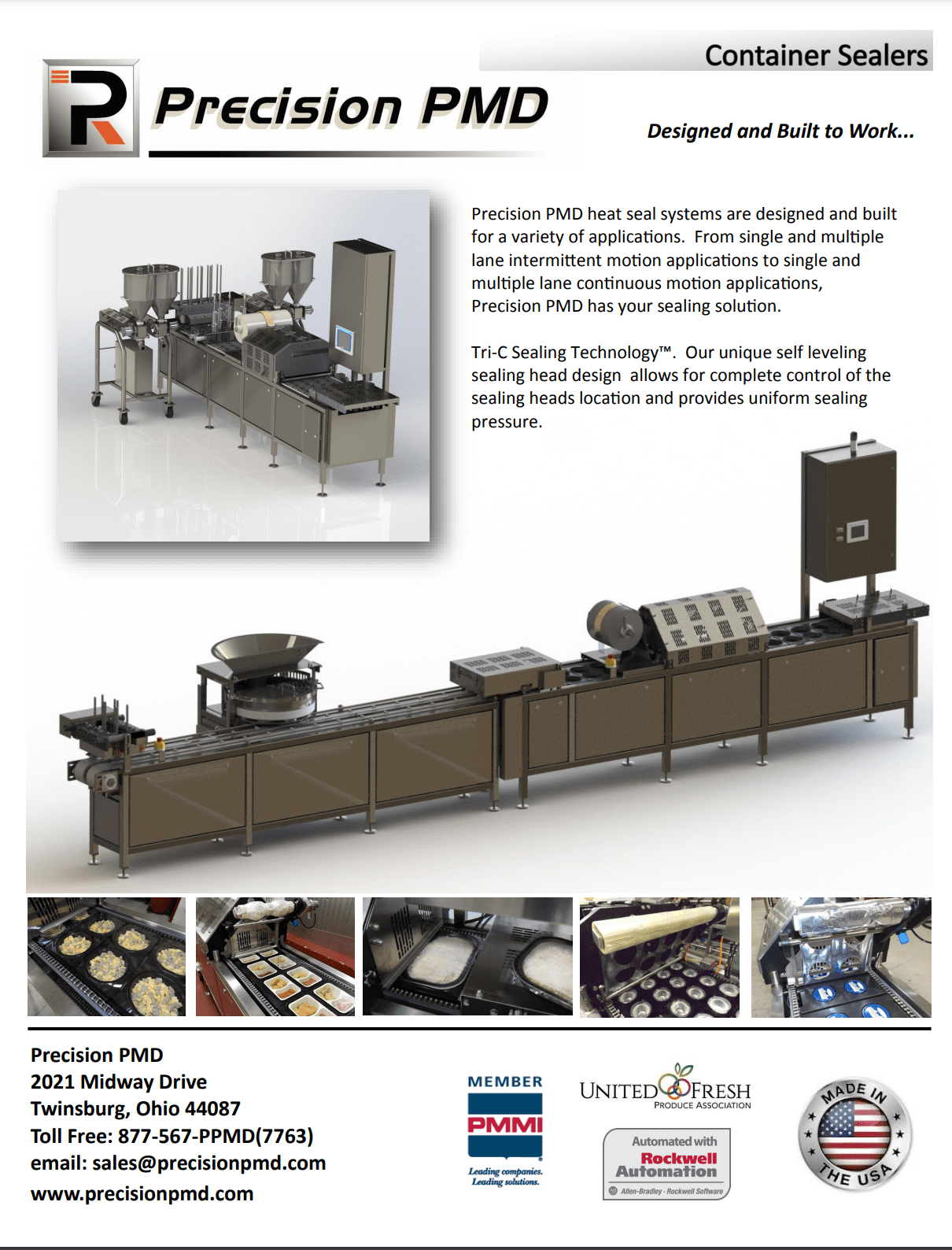

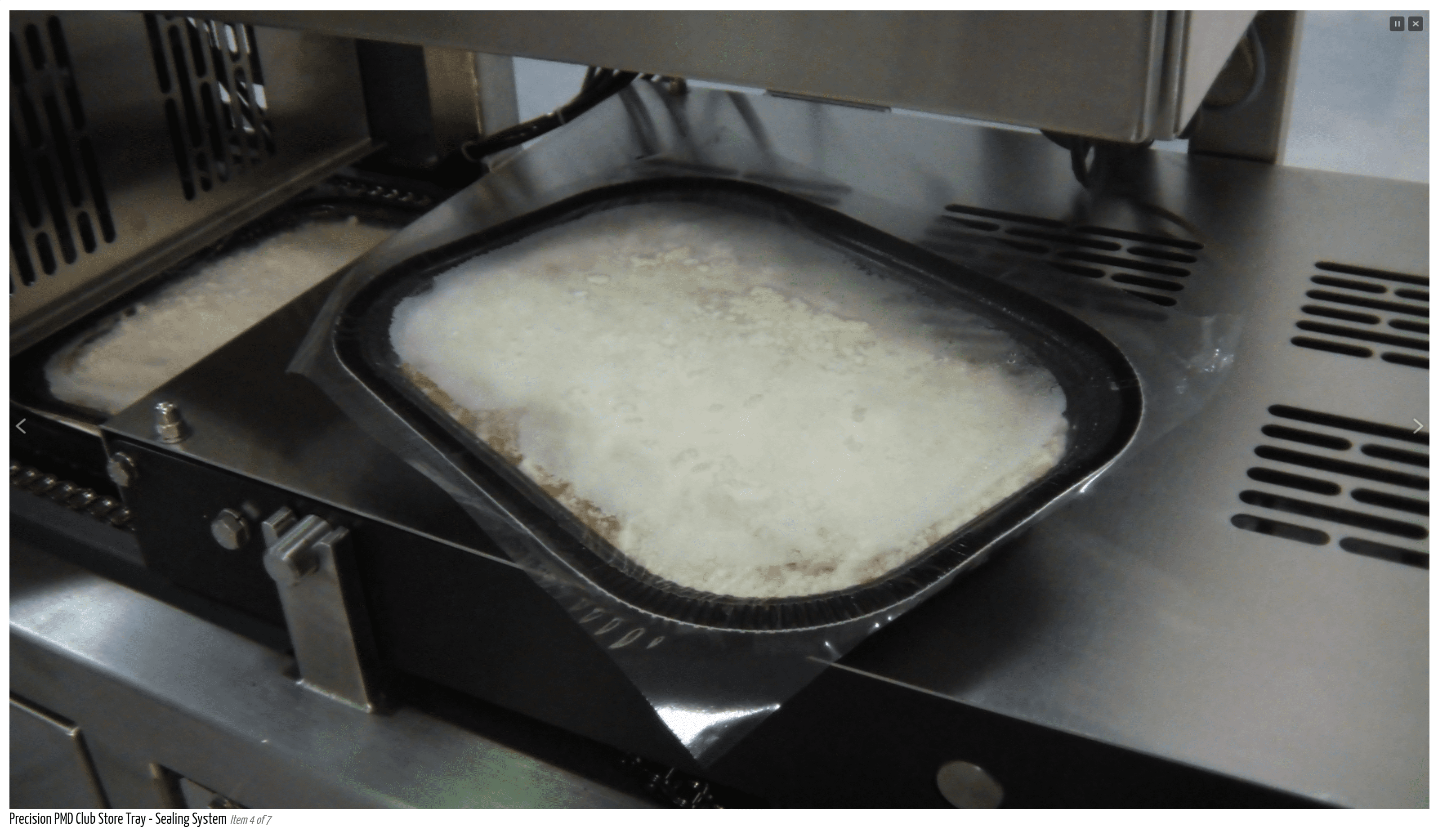

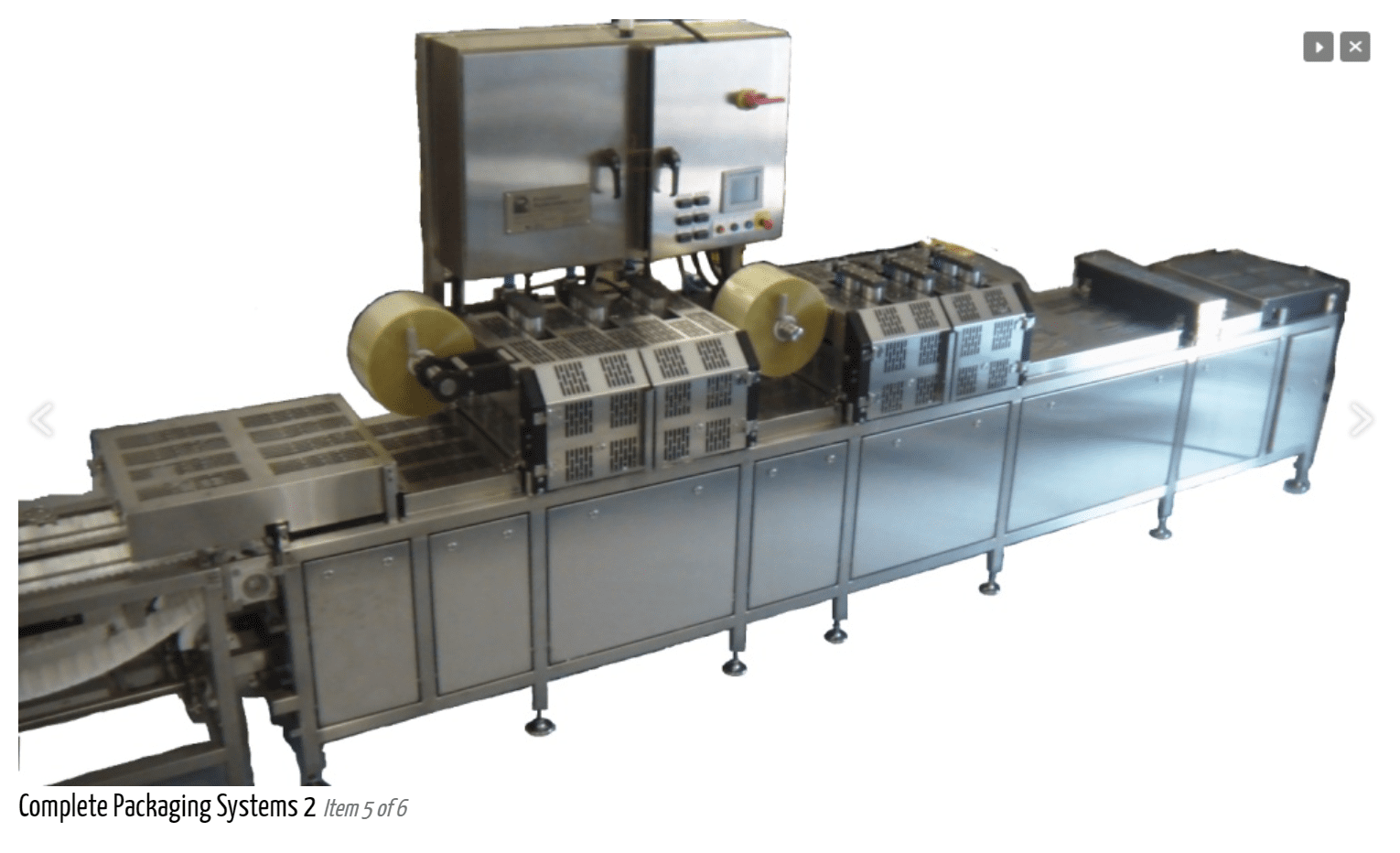

Sealers

Precision PMD Food Sealer Machine

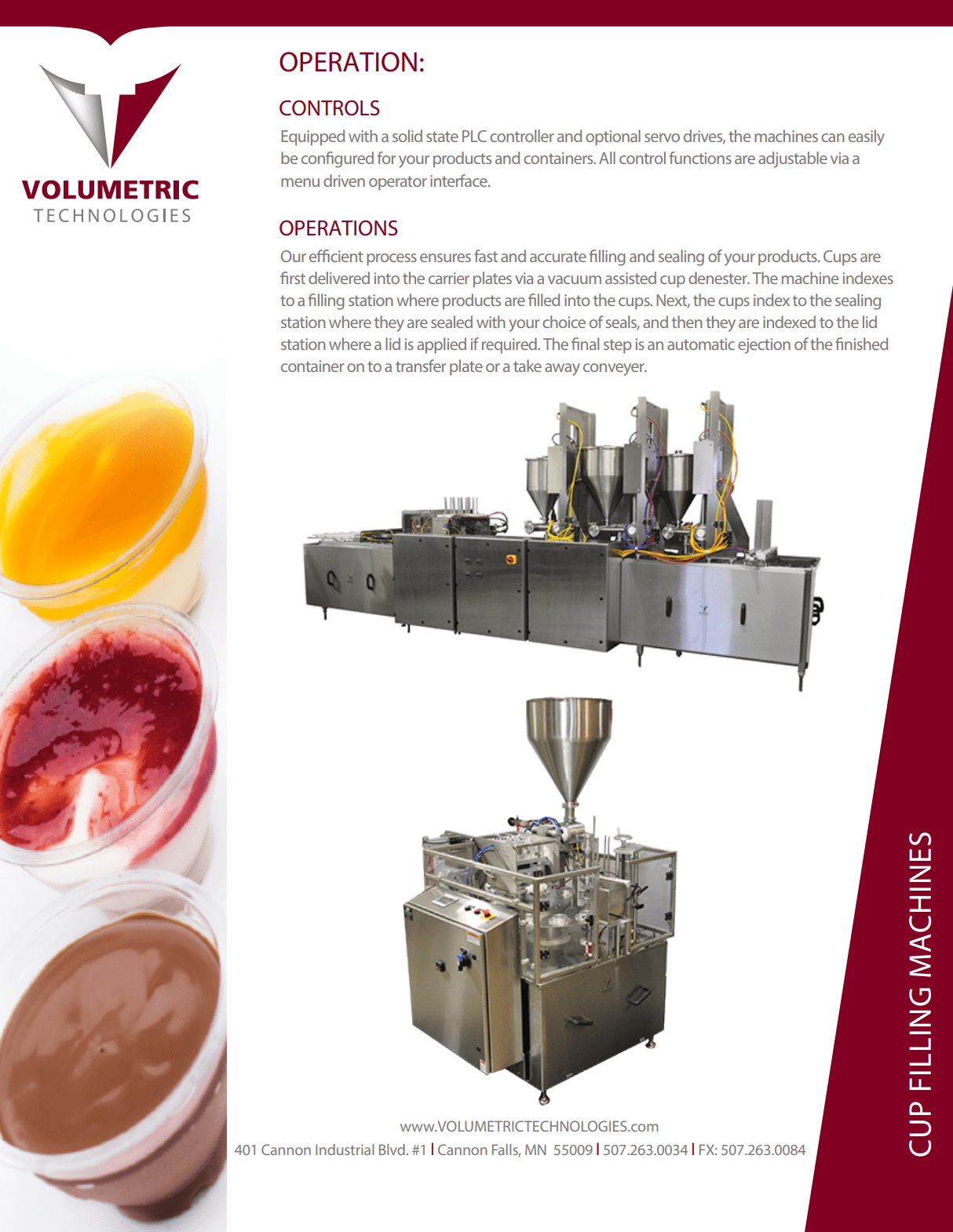

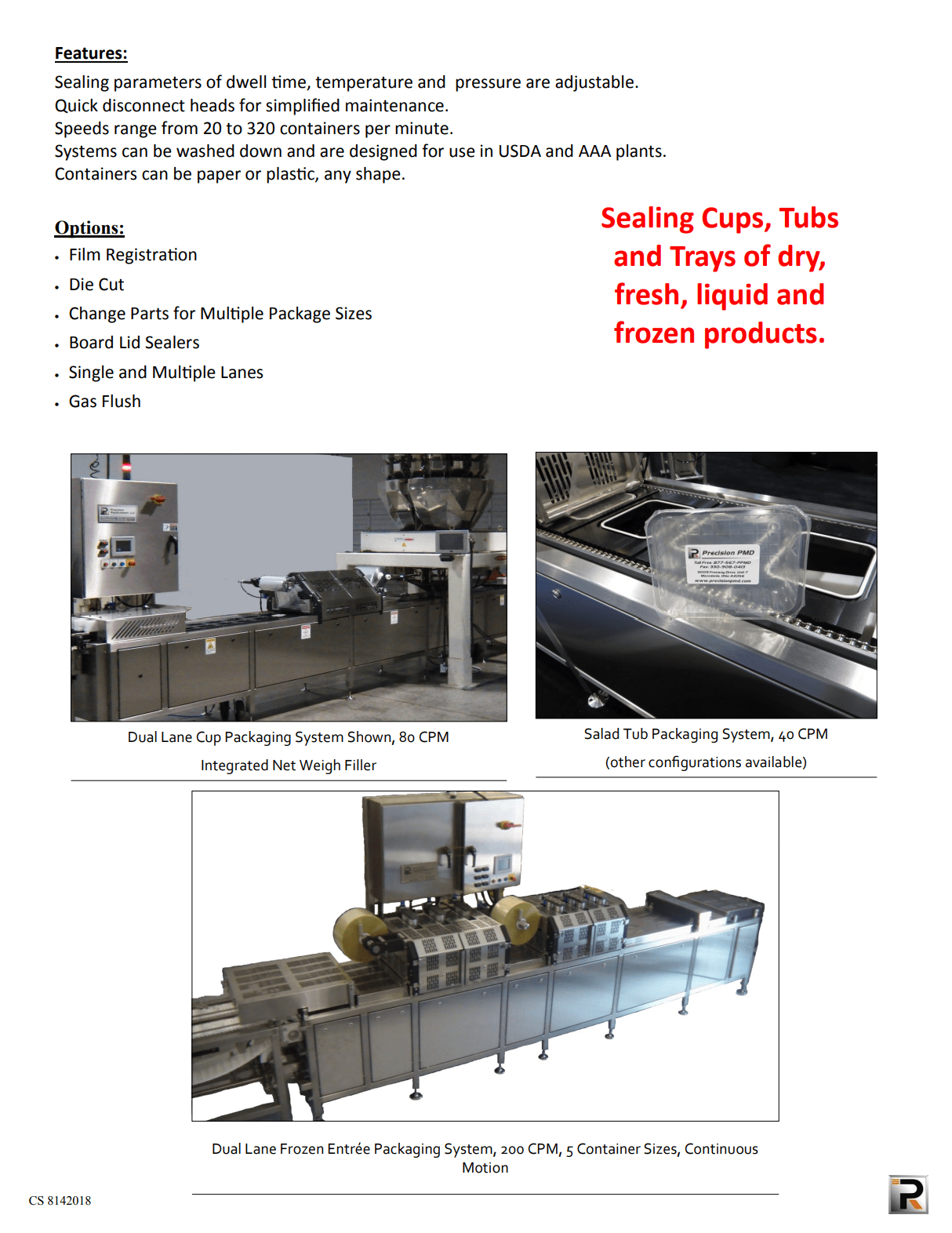

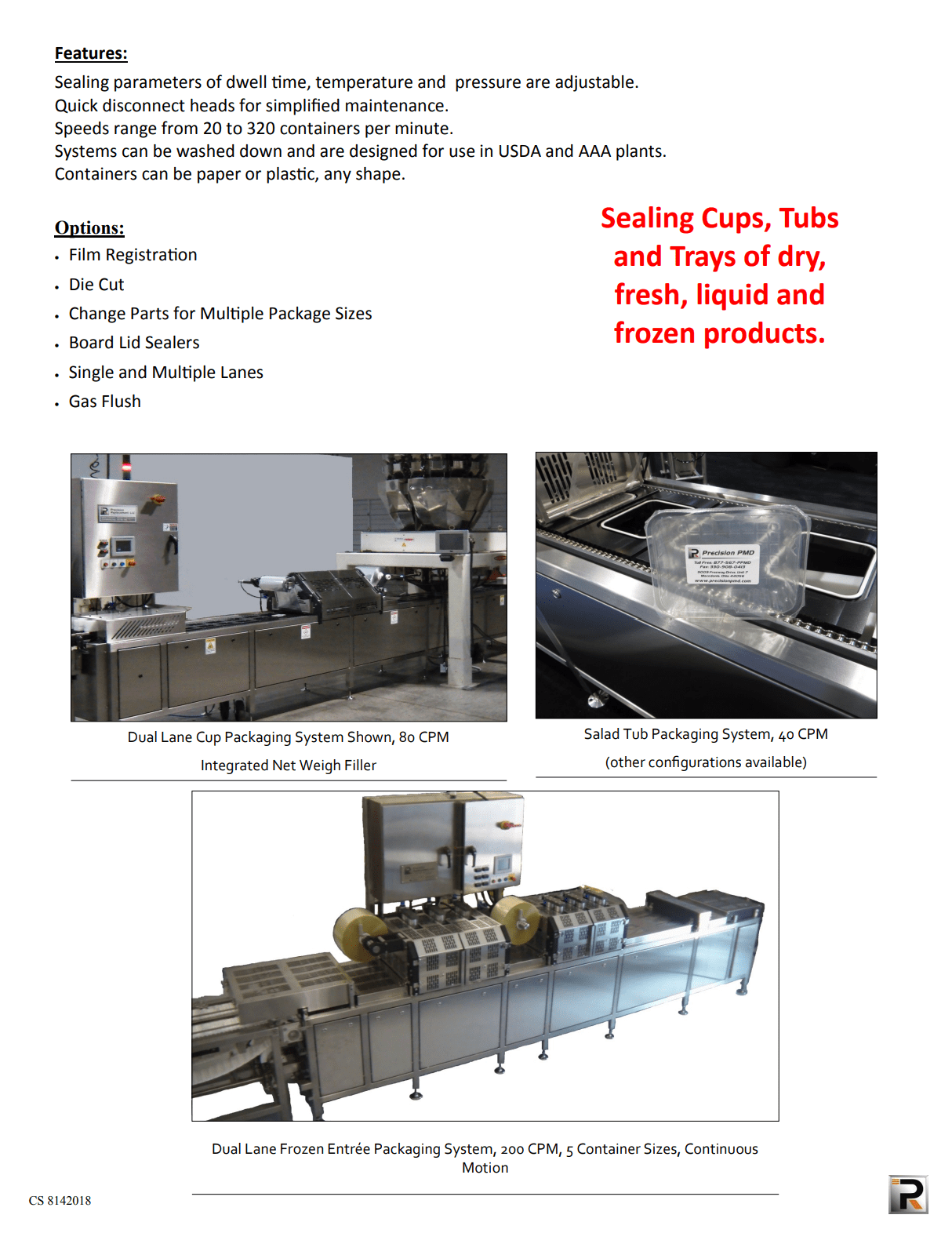

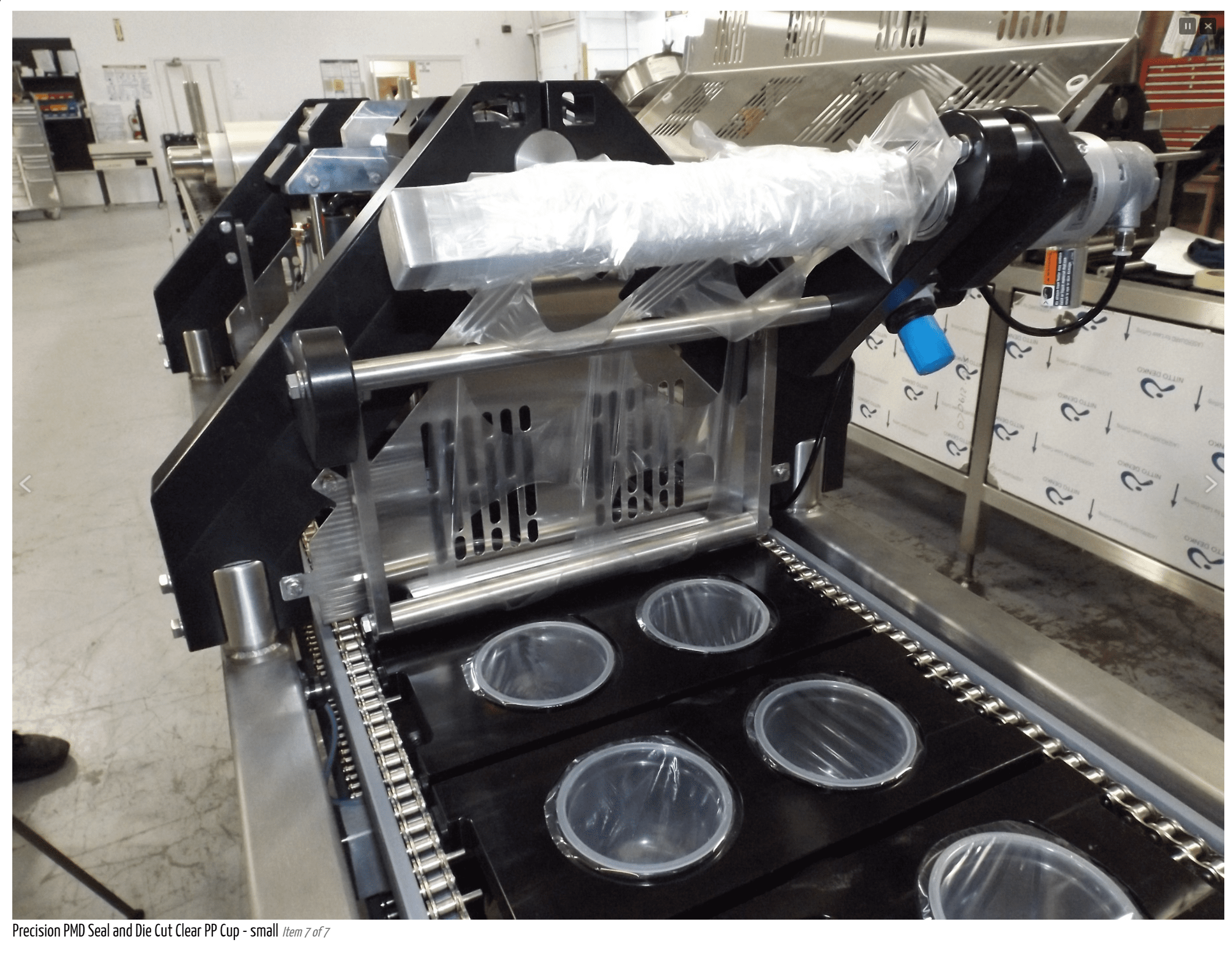

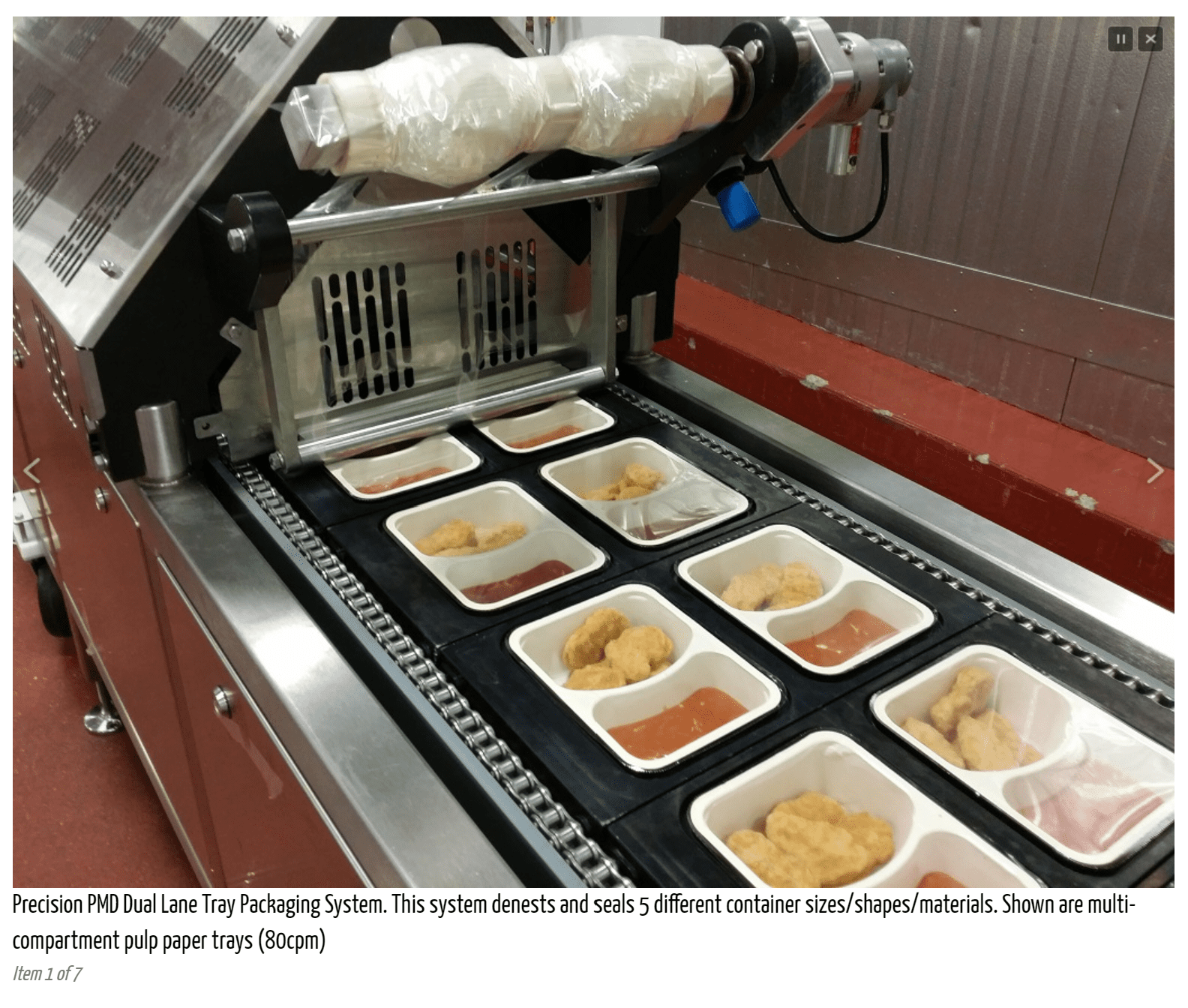

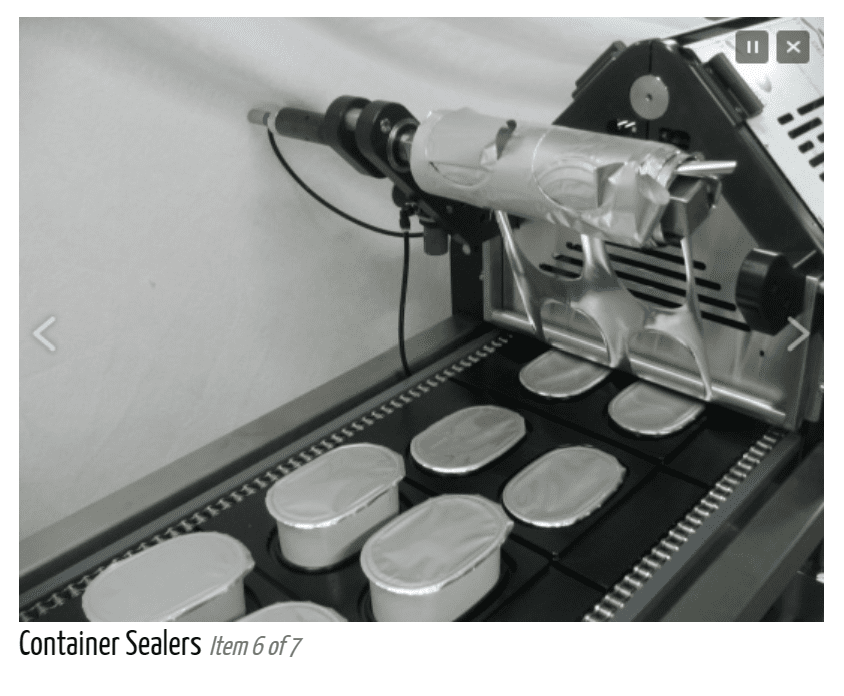

Precision PMD designs and manufactures film membrane sealing systems for pre-formed and semi-rigid containers. Sealers can seal paperboard, plastic trays, and cups with either Intermittent or continuous motion machines.

The majority of these sealers are used in the food industry, hence our frames are constructed of stainless steel tubing and aluminum is hard coat anodized for exceptional GMP. All three sealing parameters are adjustable: temperature, pressure, and dwell (contact time). These sealer systems can cut the film simply between the containers or can die-cut (perimeter cut) around the container. We can also place pre-cut foil lids which results in no film cutting, no film waste.

Optional features commonly found on the PMD container sealers include film registration, nitrogen flushing, and quick change seal and die cut heads.

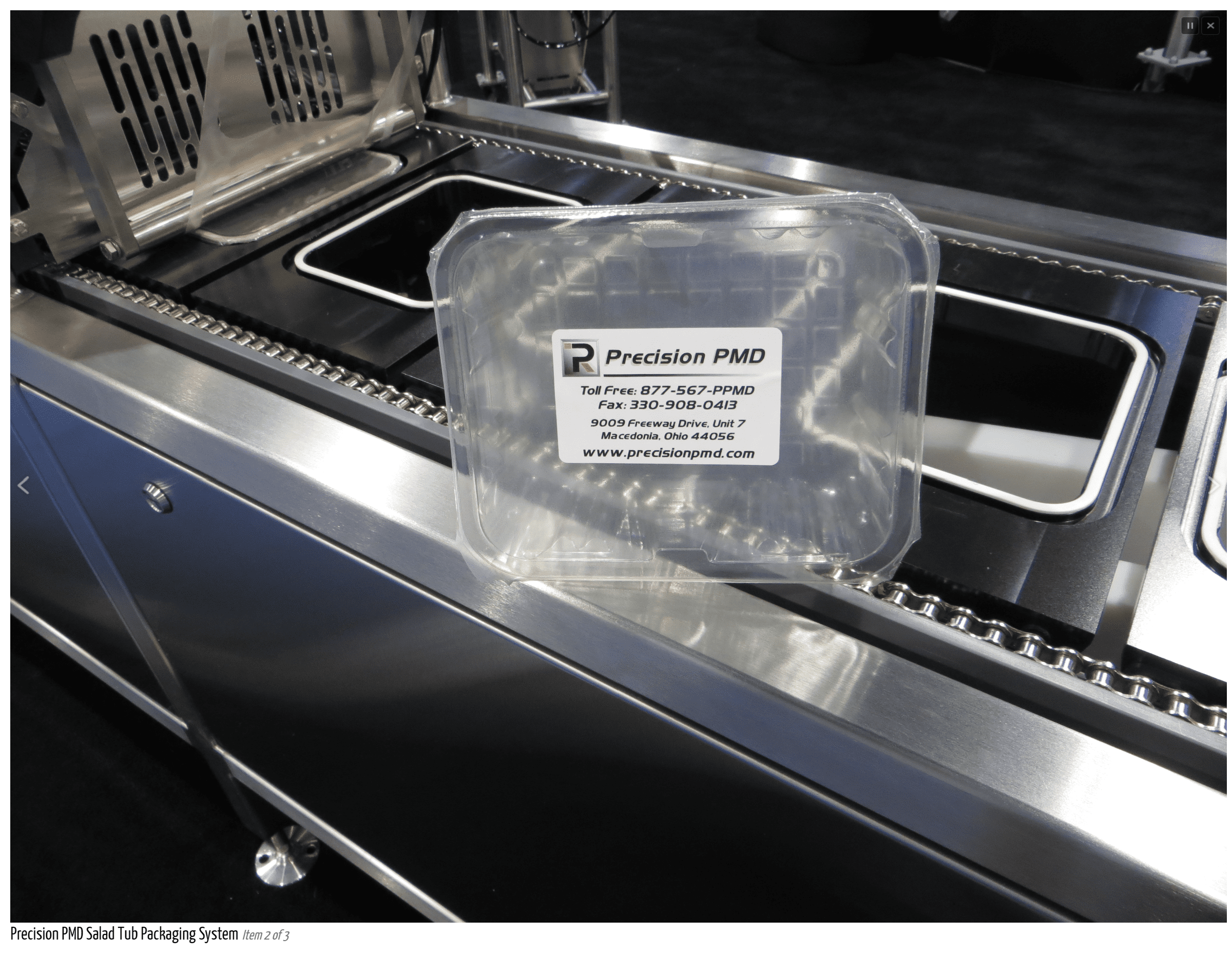

Salad Tub

Precision PMD Filling and Sealing Machine - Plastic Food Containers

Precision PMD has the solution for your salad, vegetable, and fruit container packaging needs. From retail and club store produce packaging to single serve fruit cups and salad bowls, we have the experience to design and manufacture a system that fits your specific needs.

PMD can also integrate their Denesters into your existing produce packaging system. In addition, we can provide a complete integrated system to also include product filling and tamping, film sealing and die cutting, lid applicators, scale integration, and 90* tray turners.

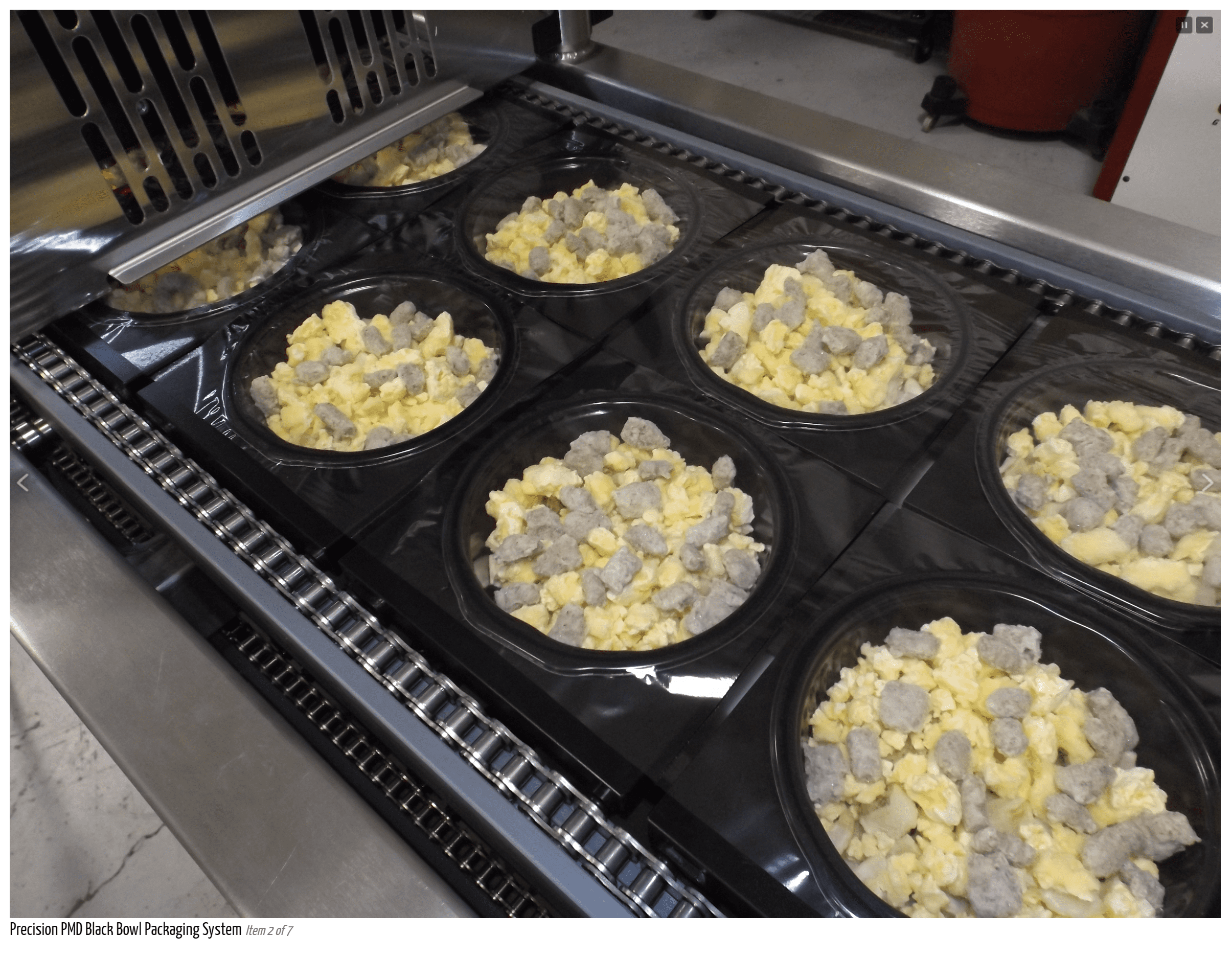

Bowl, Cup, Tray, Tub

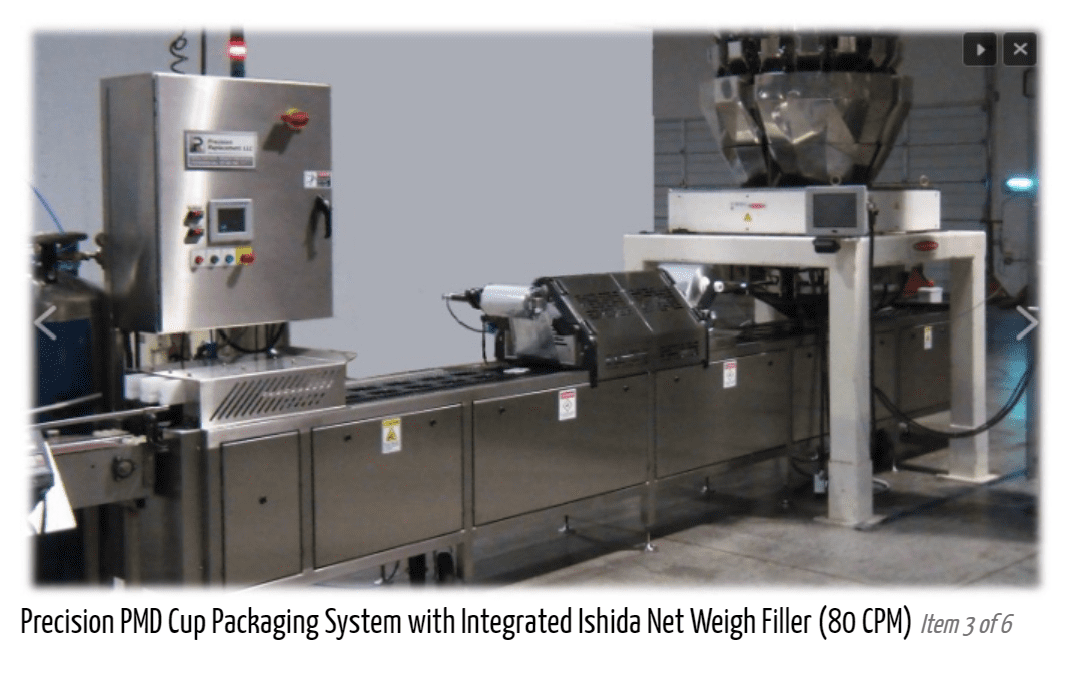

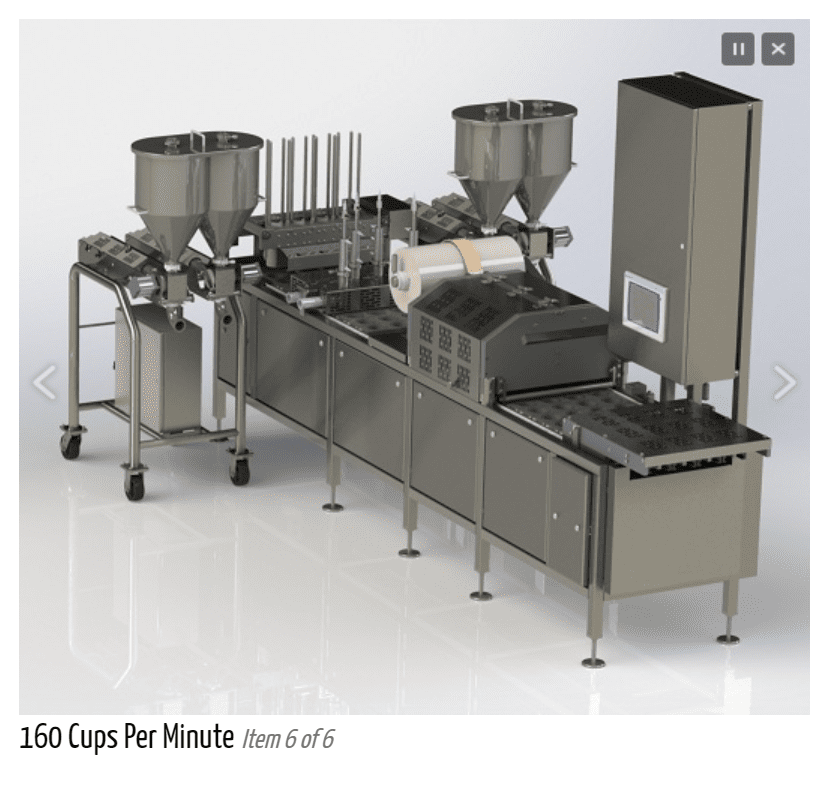

Precision PMD Rigid Container Packaging Machine

Precision PMD can provide complete production lines for packaging fresh, frozen, and dry products. The system starts with a Precision PMD Denester, where we will place the Bowl, Cup, Tray, Tub, onto a conveyor for filling.

The type of filler to be used will be based on your products. Precision PMD has filling solutions for pumpable items to dry and IQF items. Once your product is filled, we will seal the container with film from a roll or pre-die cut lids. Finally, lid applicators are available to place a lid on the container. Examples of some of the more recent machines designed and manufactured can be viewed on the image carousel.

Systems range in speed from 40 to 300 containers pm.