Rotary Liquid

Filling Machines

Volumetric Fillers and Net Weight Fillers

What's the difference?

Liquid filling machines are used by packagers to pour liquid items of varying viscosities into rigid containers. Products like water, beverages, sauces, jams, oils, foamy soaps, chemicals, nutraceuticals, cosmetics, and more.

VOLUMETRIC FILLING MACHINES use a time-based filling concept to fill containers with a constant volume of goods. Volume is a measure of the amount of space something takes up.

NET WEIGHT FILLERS use the measurement of weight, or an objects heaviness. It works like having an advanced electronic weighing scale underneath the bottle to tell you how much product you have filled into the bottle.

We offer individual filling equipment to complete line integration solutions. Our designs emphasize manufacture of high quality filling machines with remote and on-site support.

Liquid Filling Machines

Net Weight Liquid Filling Machine

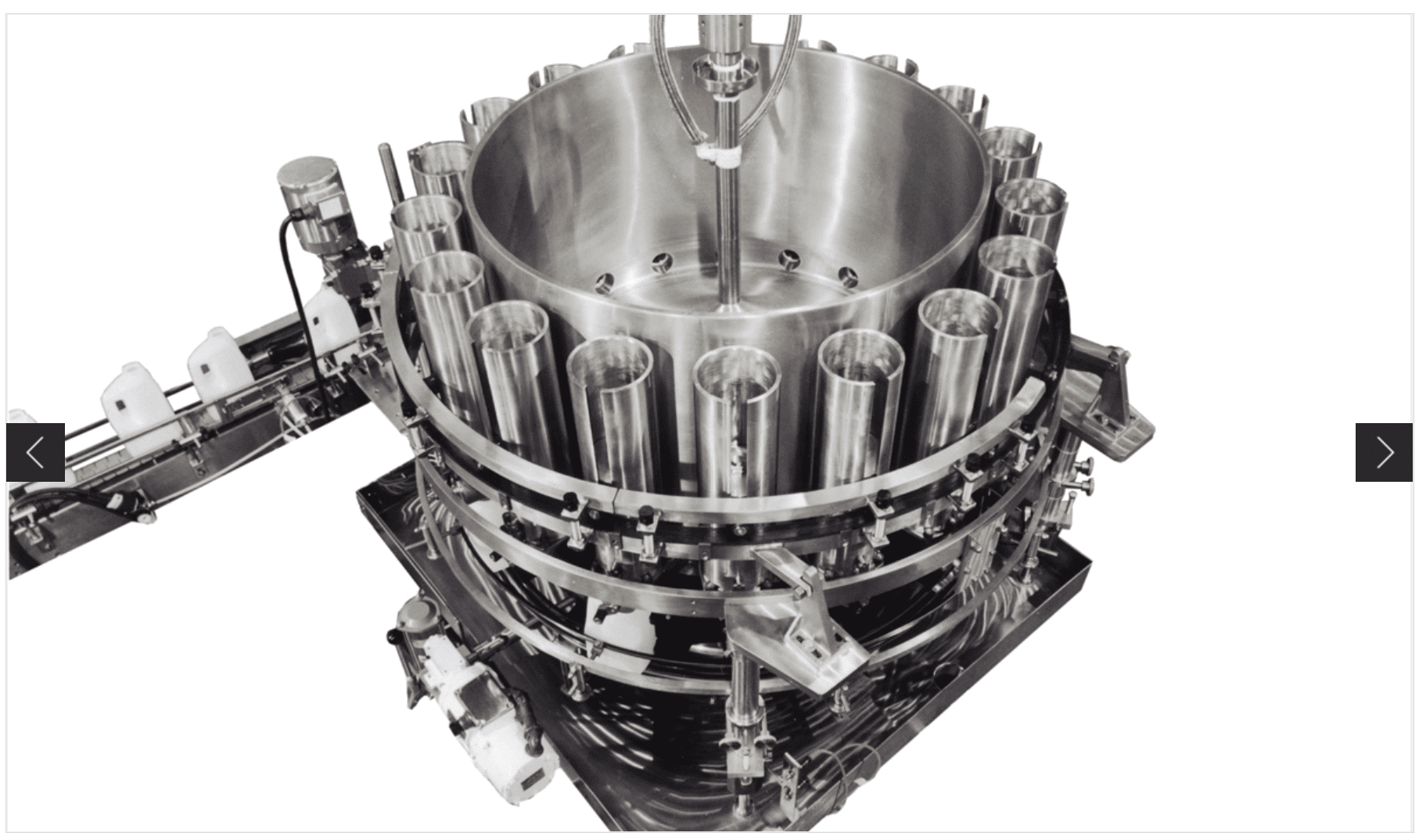

Net Weight Rotary Liquid Filler

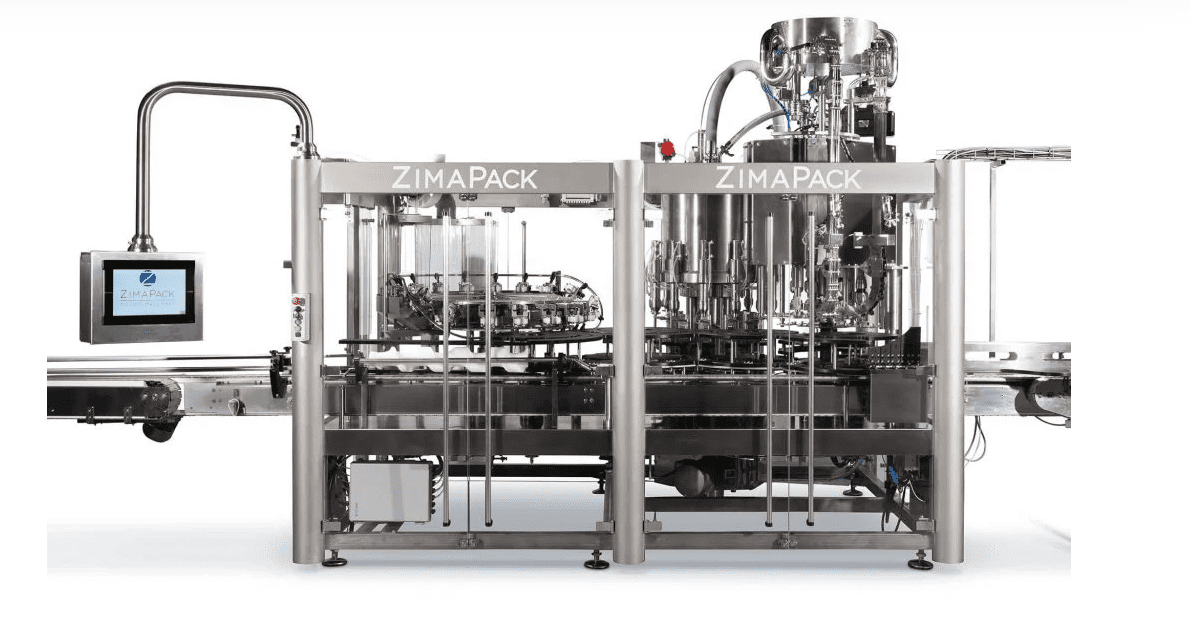

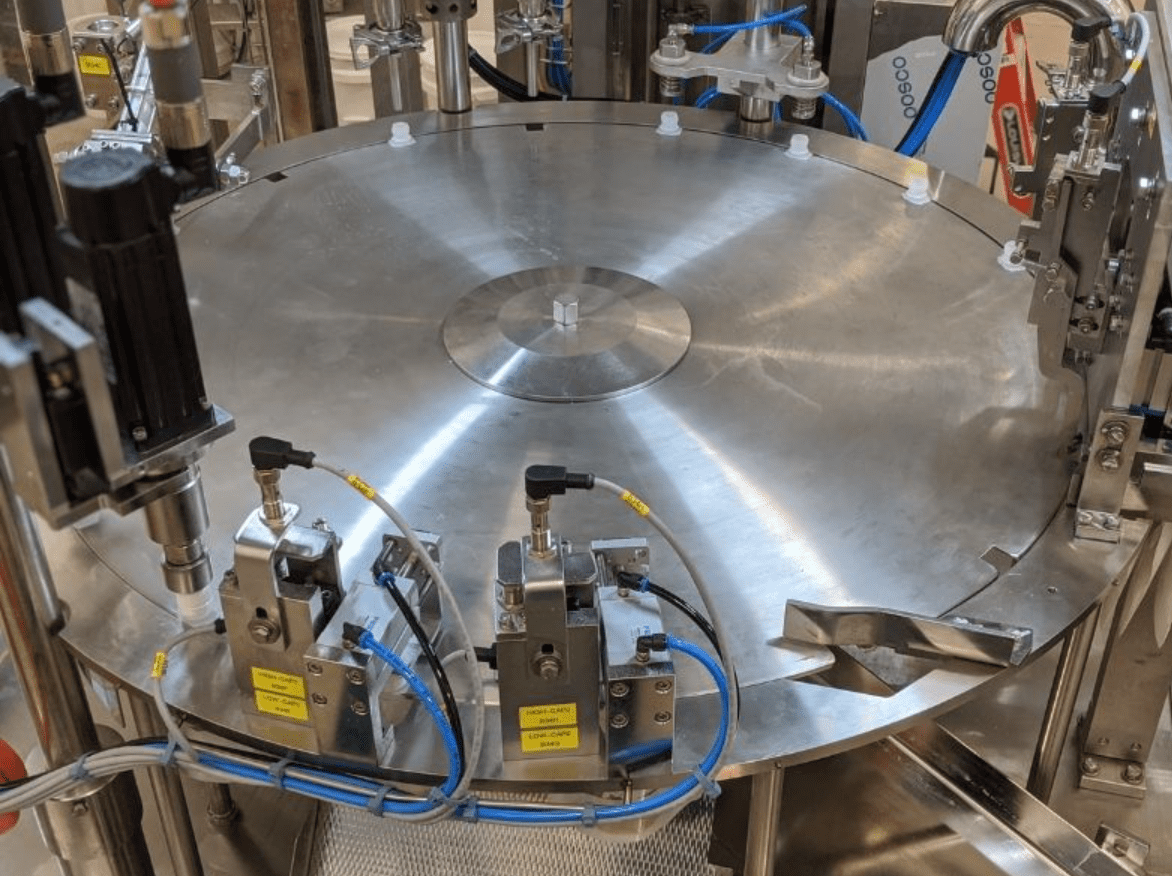

ZimaPack Rotary Net Weight Filler

Our filling machines are designed to fill fluids, such as liquids, pastes, and creams, into bottles, jars, pails, cans, most rigid containers or those that can be held by the neck opening. In addition to being faster and more uniform than manual filling, filling machines also require fewer people to operate. As an additional benefit, it makes product contamination far less likely.

ZimaPack prides themselves in having bottle filling machines with the concept of filling by net weight. While volume changes with variables like temperature and barometric pressure, net weight remains constant.

Here’s what they do:

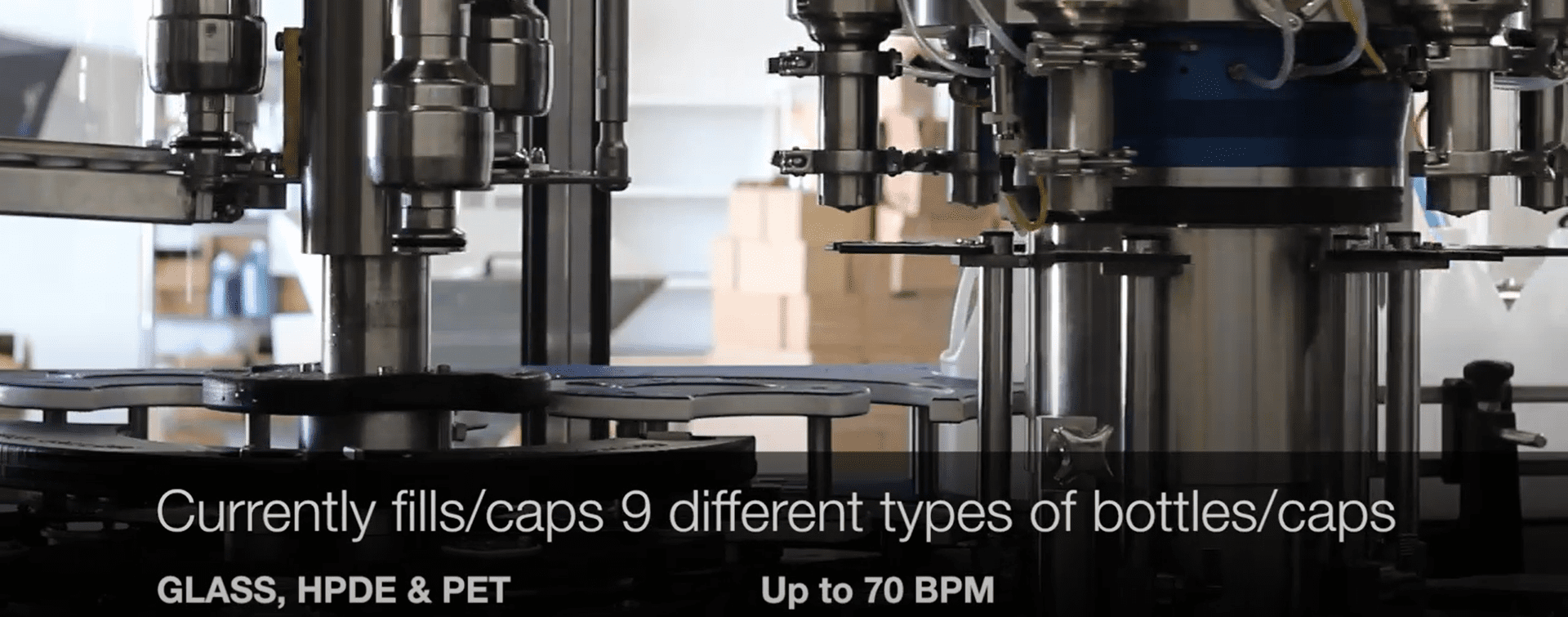

- They are typically for speeds above 40 BPM to 600 BPM.

- They can handle a wide range of product viscosities and fill sizes from 1ml – 10000ml.

- They are continuous motion machines with positive bottle handling

- Can customize to Monoblock design with Rinser and/or Capper.

- Want to combine your filler and capper and/or rinser?

Contact FES to take a look at our Monoblock machines. Our machines create a perfect solution for controlling your product giveaway and costs. Here is how you can take advantage of our Filling Machines:

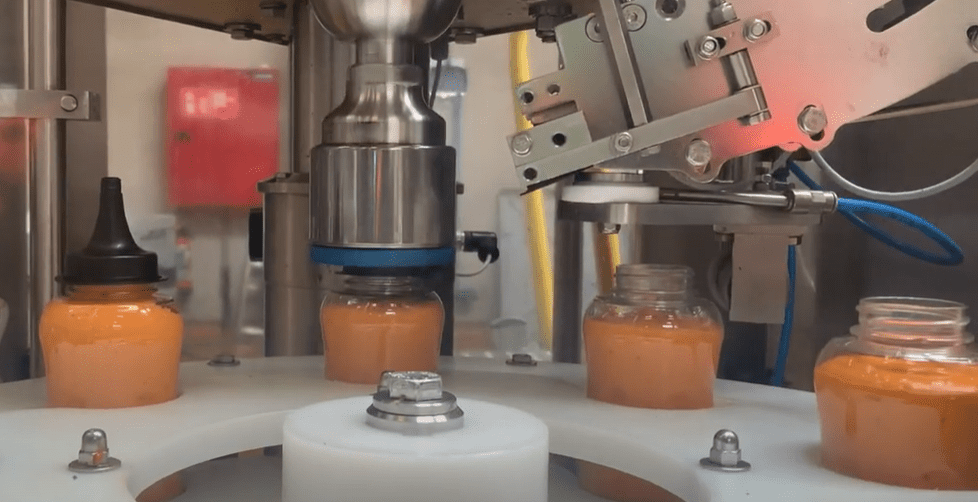

Custom Designed Nozzles. Our nozzles are created with ease of use, cleanliness, and longevity, perfect for filling rigid containers like bottles, spray bottles, detergent bottles (with or without handles), cans, pails, tubs, buckets, and so on. They are built in Stainless Steel 316L. The nozzle tips/plungers can be interchanged to accommodate a larger range of products and bottle openings. The nozzles do not penetrate the bottle during the filling process, preventing cross-contamination and ensuring overall cleanliness.

Versatility. The ZimaPack machine can accommodate a wide range of products designed with nozzles and nozzle tips, capping heads, tanks, special features, and quick tool-less bottle and cap change parts. We can make the machinery as adaptable as possible to meet a wide range of filling applications.

Clean In Place System. ZimaPack filling machines are equipped with a Clean In Place (CIP) system internally and externally. There is also an option to integrate foam cleaning systems. CIP recipes can be linked and saved with each product recipe. This way, you wouldn’t need to program this sequence each time, as some products may take longer to clean than others, maximizing efficiency and speed. There is an automatic trough that can collect the CIP solution/waste. Everything is piped for the internal CIP and external CIP so that you will have one collection point on the machine making it easy for changeovers.

ZimaPack Monoblock Filling and Capping Fresh Juice & Juice Concentrate

ZimaPack Monoblock Rinser, Net Weight Filler & Capper

Monoblock Filling Machine

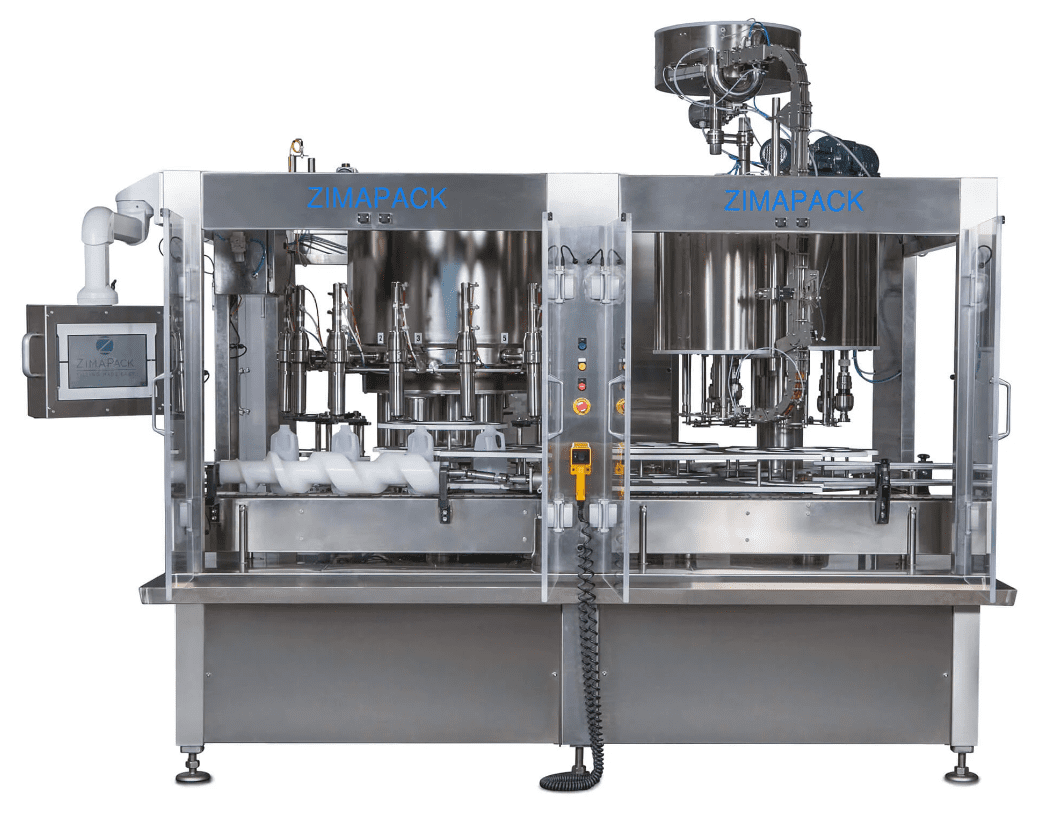

ZimaPack Monoblock Net Weight Filler

High Viscosity Acceptance Test

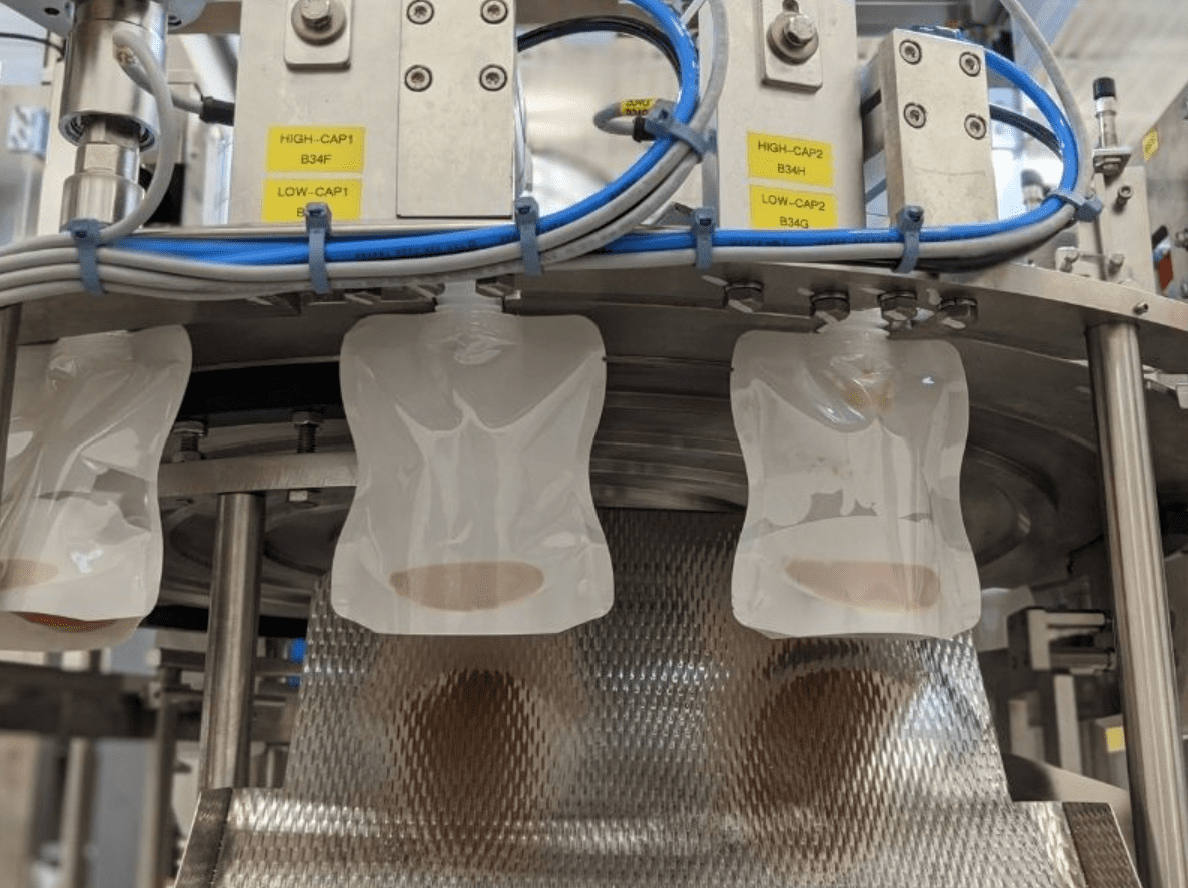

ZimaPack offers safer, cleaner ways to clean, fill and cap bottles with our Monoblocks. Our process prevents the bottle from traveling uncapped, which reduces spill risks. Moreover, it saves space on your plant floor, is cost-effective, and has fewer electronics and spare parts. Generally, it requires less maintenance and is easier to clean.

How do they work?

- Our optional rinsers are designed to clean bottles with ionized air, water, or solution.

- Each net filling station has a load cell, pneumatically controlled filling nozzle, and bottle plate. The weight is calculated over 2,000 times per second while filling.

- Our machines are entirely PLC based. The touchscreen HMI is operator-friendly and allows for programmed recipes for each product/container.

- Our filler turrets include an internal Clean In Place (CIP) with spray balls that wash the tank and all components in contact with the product. They also have an external CIP that washes the machine parts inside the protection guards.

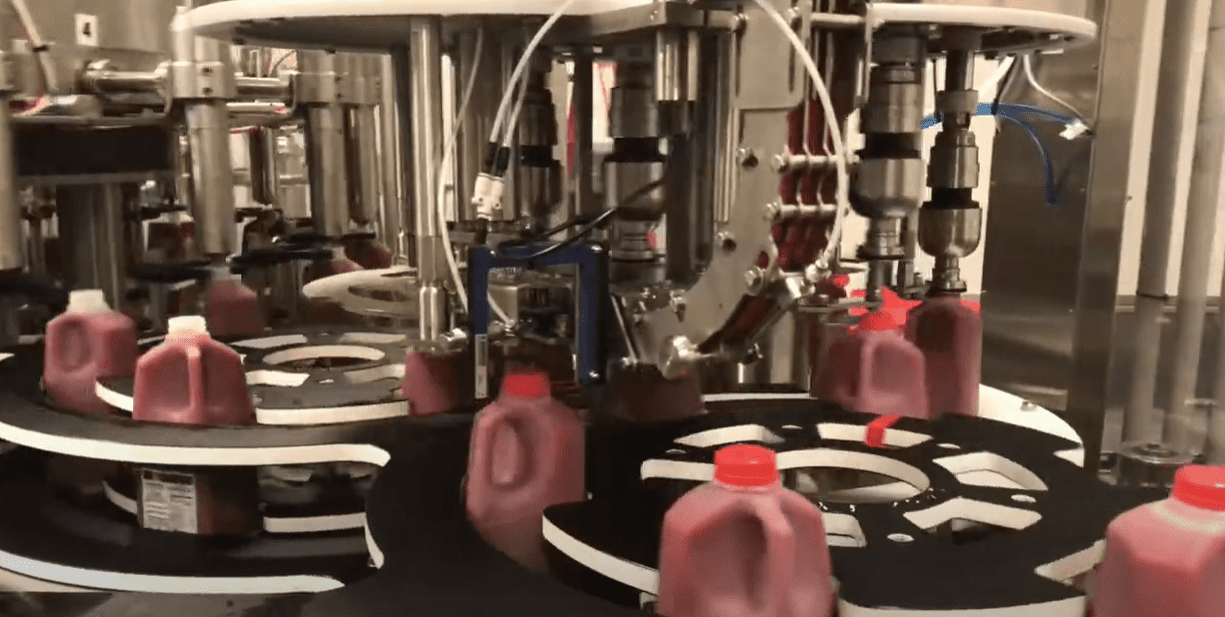

- Our capping turrets offer a range of solutions to fit any production needs. They can be designed to accommodate multiple types/sizes of caps with dedicated cap chutes. We use Mechanical Clutch Style Capping Heads to achieve torque and a precise seal each time!

- Check out our Filling Machine Page & Capping Machine Page for for more information & options.

Custom Designed Nozzles. Our nozzles are created with ease of use, cleanliness, and longevity, perfect for filling rigid containers like bottles, spray bottles, detergent bottles (with or without handles), cans, pails, tubs, buckets, and so on. They are built in Stainless Steel 316L. The nozzle tips/plungers can be interchanged to accommodate a larger range of products and bottle openings. The nozzles do not penetrate the bottle during the filling process, preventing cross-contamination and ensuring overall cleanliness.

Versatility. The ZimaPack machine can accommodate a wide range of products designed with nozzles and nozzle tips, capping heads, tanks, special features, and quick tool-less bottle and cap change parts. We can make the machinery as adaptable as possible to meet a wide range of filling applications.

Clean In Place System. ZimaPack filling machines are equipped with a Clean In Place (CIP) system internally and externally. There is also an option to integrate foam cleaning systems. CIP recipes can be linked and saved with each product recipe. This way, you wouldn’t need to program this sequence each time, as some products may take longer to clean than others, maximizing efficiency and speed. There is an automatic trough that can collect the CIP solution/waste. Everything is piped for the internal CIP and external CIP so that you will have one collection point on the machine making it easy for changeovers.

ZimaPack Glass Bottle with Glass Dropper

Filling and Capping Test

ZimaPack Monoblock Ionized Air Rinser Filler & Capper

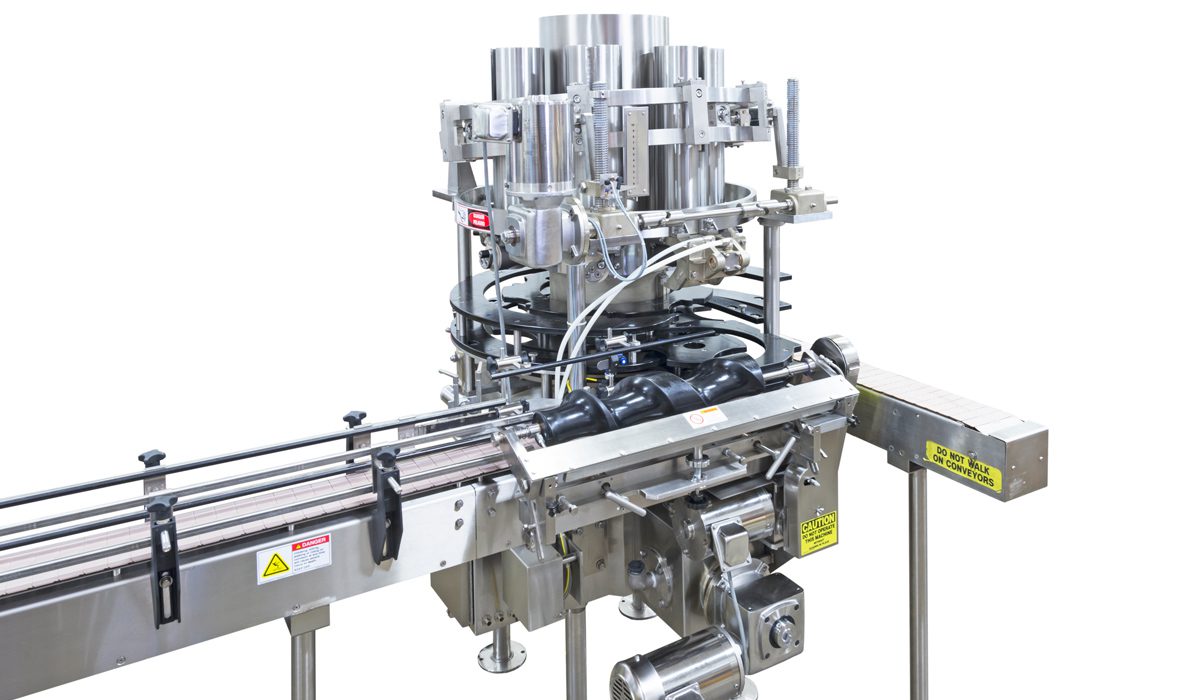

Capping Machine

ZimaPack Automatic Rotary Pump Inserter Chuck Style Capping Machine

ZimaPack’s capping machines offer Semi-Automatic and Automatic Cappers. We can work with a wide range of containers and cap sizes, shapes, closures, various capping heads, specific chutes, sorters, and elevators. We only use Clutch-Style Capping Heads for our capping machines. Here is why:

Accomodates different types of caps – Allows for a very tight seal. Clutch-style capping heads are designed for various types of caps. They have a series of teeth that grip the cap and can be tightened or loosened to adjust the grip, making them ideal for use with both standard and non-standard caps. The Clutch-Style Capping heads allow for the torque to be adjusted for a perfect tight seal. It is essential because it means your product will be well-protected from the elements.

Why Choose Clutch Style Capping Heads? Clutch capping heads provide consistent and reliable capping without the fear of breakage, as with inline capping systems. It also allows a consistent and appropriate torque to be applied, ensuring a secure seal. With an inline capping system, there is no control of torque, which can cause inconsistencies in capping quality and potential breakage.

Types of Capping Heads. Our capping heads are the perfect way to seal your bottles quickly and precisely. We can build a Capping Machine to accommodate several different types of caps to promote versatility on your packaging line. Our experts can help you find the ideal capping head for your needs. We offer a solution for the following types of caps:

- Regular Flat Screw Caps

- ROPP Caps

- Press-On Caps

- Pump Caps

- Trigger Caps

- Flip-top Caps

- Sport and Push-pull Caps

- Dispenser Caps with or without pouring spouts

- Twist Caps

- Droppers (eye drops and dosing)

ZimaPack Rinsing, Filling & Capping Bottles

ZimaPack ROPP Capper - Monoblock

Cup Filling Machine

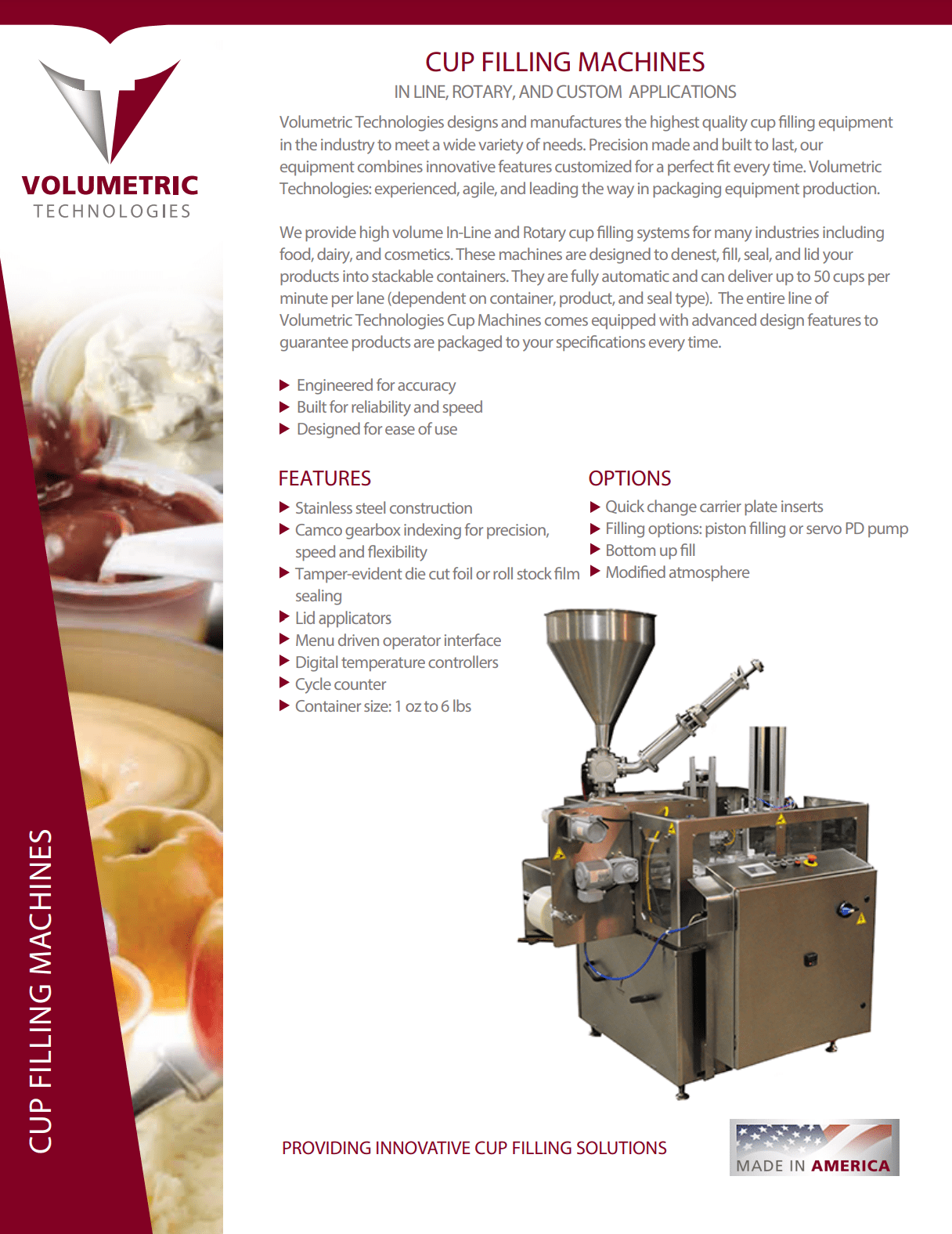

Volumetric Technologies

Cup Filling Machine

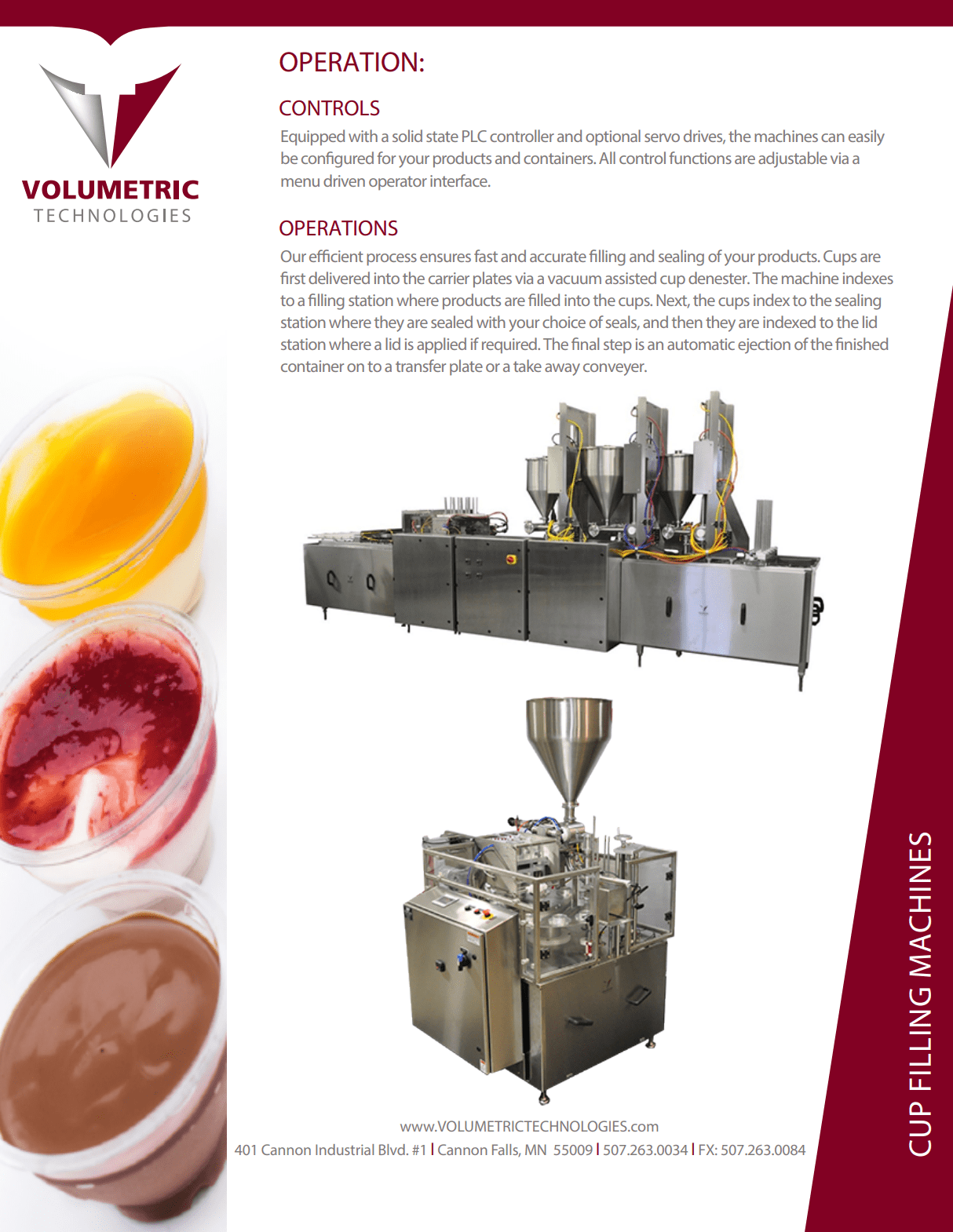

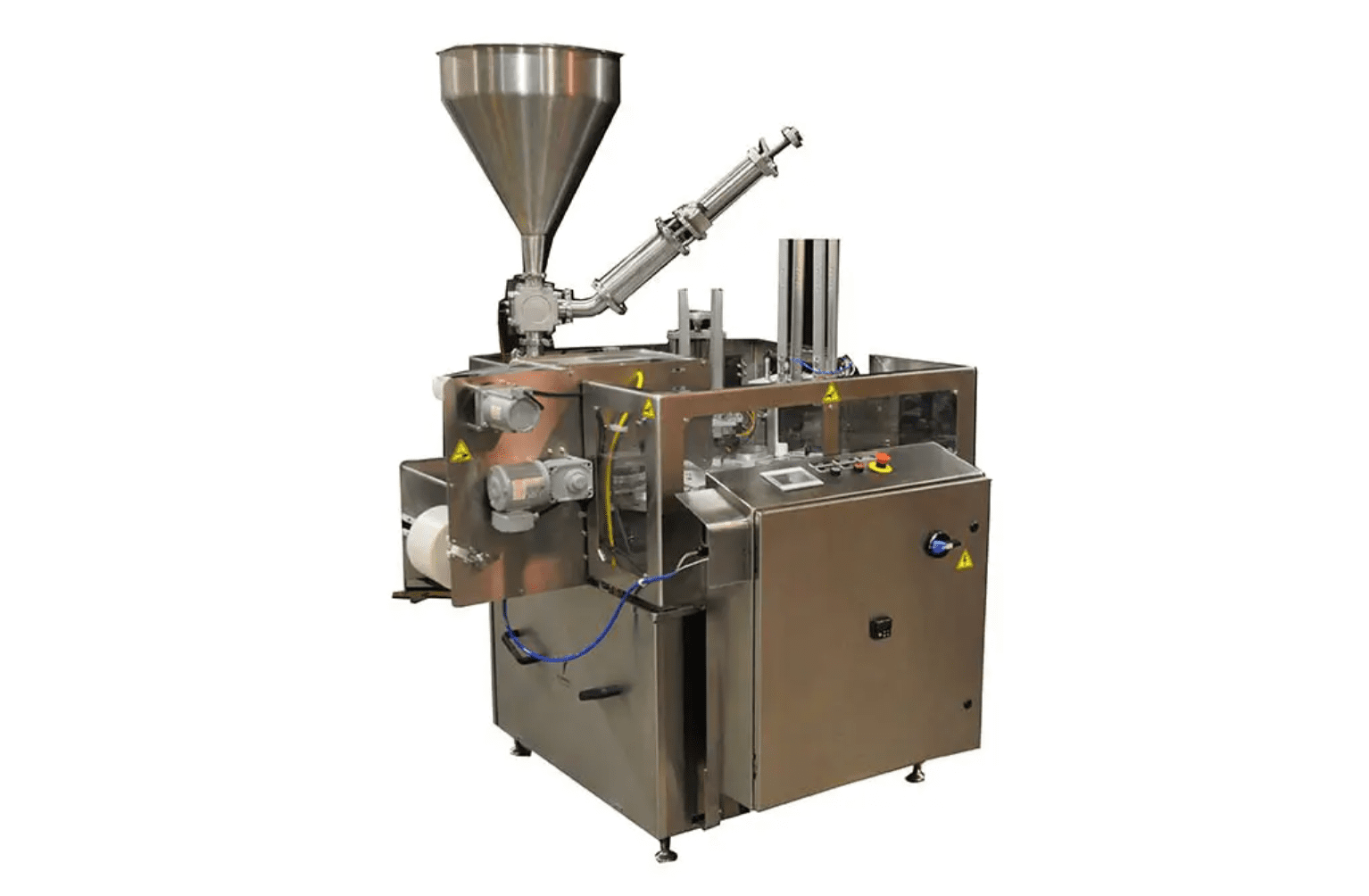

Volumetric Technologies provides reliable, accurate, high volume Cup Filling Machines for many industries including: Food, Dairy, and Cosmetics. These machines are designed to de-nest, fill, seal, lid and eject your products.

Our Rotary Cup Machines are fully automatic and can deliver up to 40 cups per minutes per lane, with configurations up to 3 lanes. The entire line of cup machines comes equipped with advanced design features to guarantee products are packaged to your specifications every time. We can fill volumes from .2 oz. up to 133 oz. with a particulate size up to 2″ in diameter and the cup filling machine is designed to be full washdown.

Equipped with a solid state PLC and a touchscreen HMI gives flexibility to configure the equipment properly for your application. All control functions are adjustable via a menu-driven operator interface.

Liquid Pouch Filling Machine

Liquid Pouch Packaging

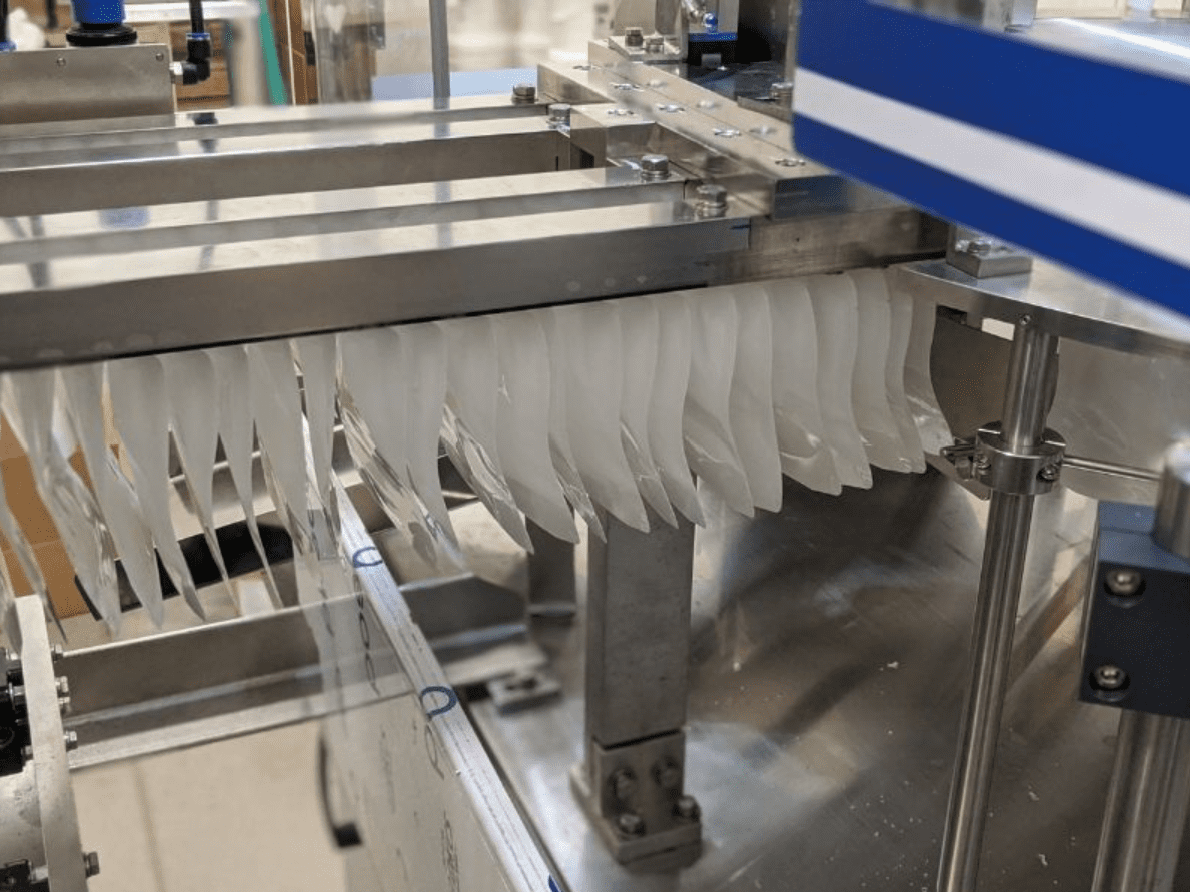

The newest premade pouch solution is Standcap Pouch, is revolutionizing premade pouch packaging. This inverted wedge-shaped pouch style features a distinctive flip-top cap that serves as the base for the finished package.

Automatically fill and cap Center Spout & Standcap pouches of liquid products like baby food, condiments, personal care. We provide a modular build with a touch screen HMI, where the spout machine is easy to maintain and simple to control, requiring only one operator. Bag sizes range in minimum width and length with maximum lengths from 100mm to 170mm and speeds up to 80 bags per minute.

PLC controls with touch screen screen HMI operation and a servo-driven Allen Bradley control platform allows operators to easily adjust the machine when product changeovers are required. Our design includes highly durable stainless steel frames with pouch presence detection – no filling, no sealing, cartridge rail type loading with liquid filling, automatic cap feeding and placing.

Available options include a CIP design with washdown for IP65, IP 66, or IP67 ratings, Ink jet printers, gas flush, and custom line integration.

Piston Liquid Filling Machine

Elmar Piston Liquid Filling Machine

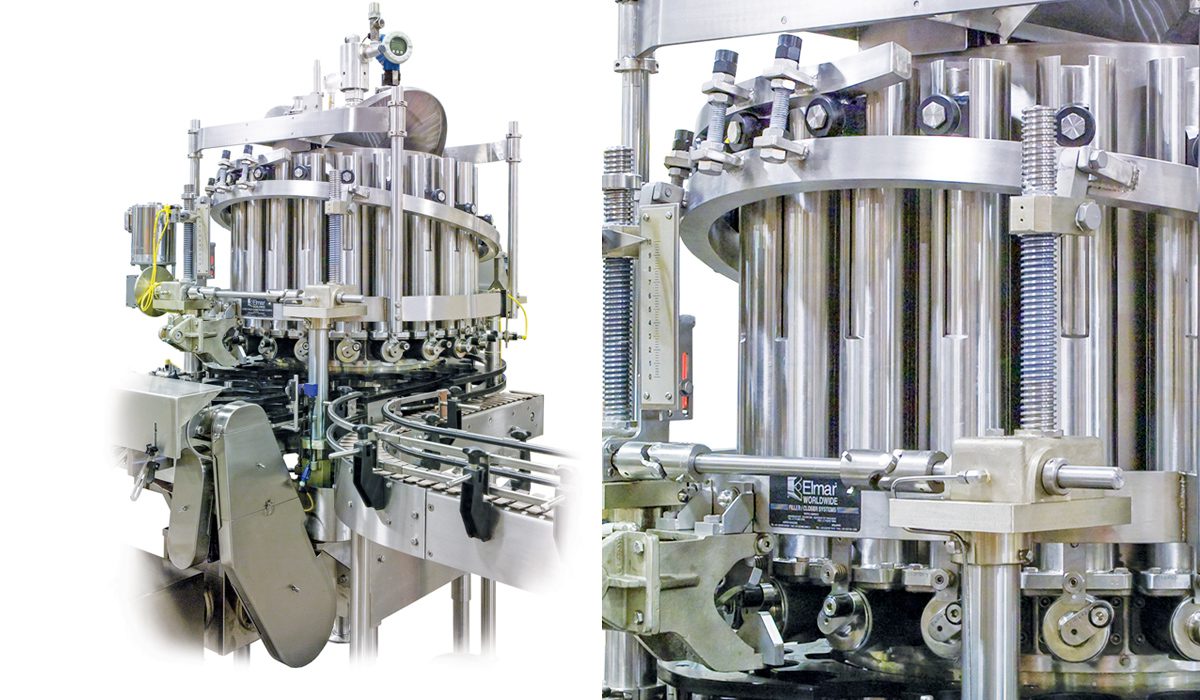

Elmar Industries offers piston fillers for your liquid filling needs. Our clients who offer liquid products and needs to fill liquids in rigid containers, Elmar offers custom deigned Rotary Piton Filling Systems.

Their no nonsense machines can be manufactured to have 6 to 81 stations. All machines come with a one-year machine warranty and have a proven history of reliability and accuracy.

Some of the design features include: temperature and level probes, bowl cover, quick change nozzles, bowl plow, inverter drive systems, tool-less change parts, motorized height adjustment, motorized volume adjustment, and bottom fill available on select models.

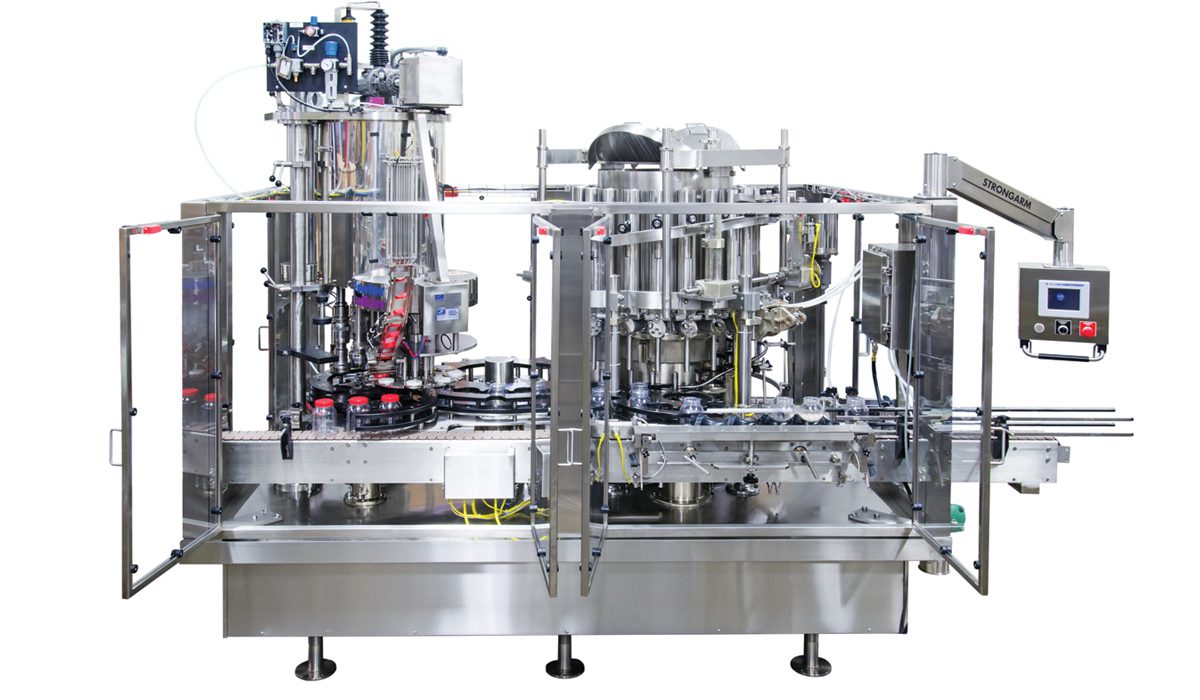

Monoblock Filling Machines

Elmar Monoblock Filling Systems are dual discharge Monoblock fillers for filling plastic, glass, or metal containers. These filling systems accurately and reliably fill, cap, and seam a wide range of products and container styles. All Elmar Monoblock Units are powered with an AC inverter motor control. This allows an infinite range of speed regulation on the Elmar control panel. Direct worm gearbox drives all turrets and stars. Each Monoblock filler comes with a 1 year warranty.

Safety features include an electronic torque limiter which guards against dangerous overload conditions if a jam were to occur. Special sensors strategically placed in the Monoblock system help to ensure a constant flow of containers including no container/no fill, no container/no cap, wrong way container detector/ejector, low cap chute, low cap hopper, etc. Custom computer electronic line control systems are available.

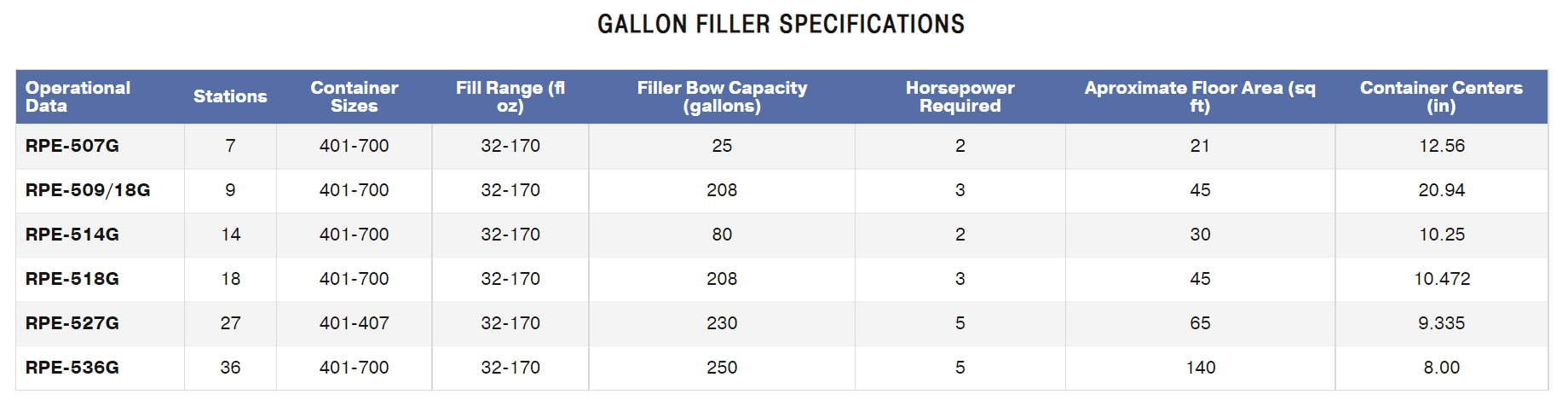

Gallon Filling Machine

Elmar Rotary Gallon Filling Machine

Elmar custom designs and manufactures one to five-gallon filling machine systems. We offer a variety of custom configurations to fulfill our customers exacting requirements with speeds up to 300 gallons per minute.

Features of the gallon filler machine technology include 1 to 5 gallon fillers, motorized volume adjustment for instant volume change, motorized height adjustment for instant height changeover, water jacketed bowl for constant product temperature, product catch basin, variable speed mixer/agitators, bowl cover, lid dropper, no-tools change parts, and in-house product testing.

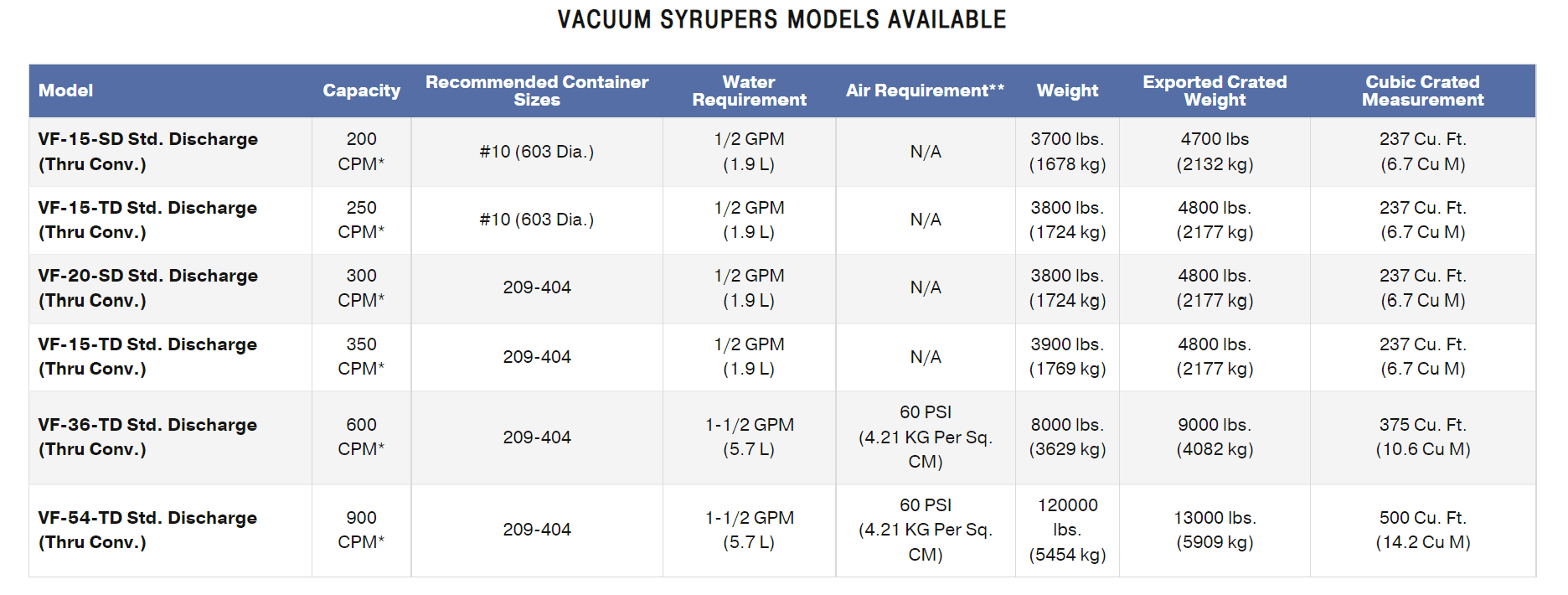

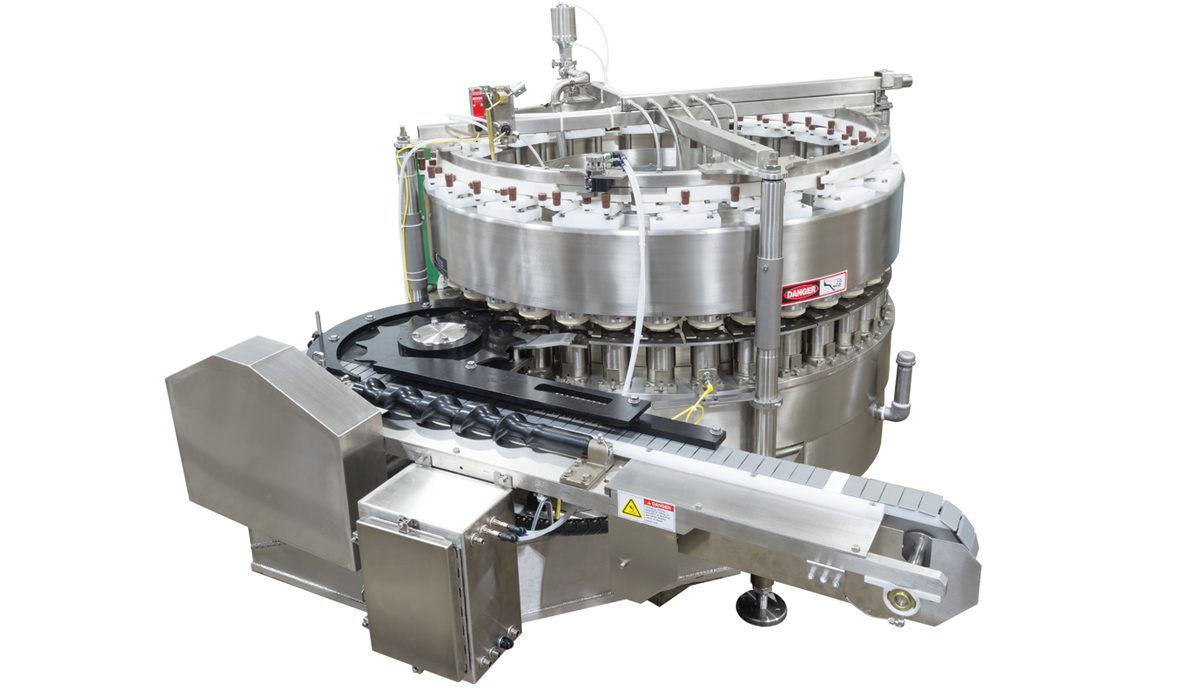

Vacuum Syruper Machine

Elmar Vacuum Syruper Filling Machines features include deep penetration of liquid to the product, elimination of an exhaust box and a specially designed valve that assures a positive seal. This positive seal prevents air leakage into containers under vacuum with a naturally self-lubricating valve that can be easily removed for cleaning.

Typical of all Elmar Liquid Filling Machines, a no container/ no fill mechanism is provided – stops the flow of liquid when a container is not present. Another feature is a stainless steel liquid trap tank for use in the vacuum line to collect moisture overflow when vacuum is applied. The trap tank can be positioned in the place most convenient to the syruper. Automatic emptying controls can be supplied with the liquid trap. This control is functional during the operation of the filler.

Elmar Vacuum Syrupers are available in through conveyor and tangential discharge configurations. Elmar Vacuum Syrupers are accurate, rapid, and waste-free filling.