Inline Liquid

Filling Machine

Volumetric Fillers and Net Weight Fillers

What's the difference?

Liquid filling machines are used by packagers to pour liquid items of varying viscosities into rigid containers. Products like water, beverages, sauces, jams, oils, foamy soaps, chemicals, nutraceuticals, cosmetics, and more.

VOLUMETRIC FILLING MACHINES use a time-based filling concept to fill containers with a constant volume of goods. Volume is a measure of the amount of space something takes up.

NET WEIGHT FILLERS use the measurement of weight, or an objects heaviness. It works like having an advanced electronic weighing scale underneath the bottle to tell you how much product you have filled into the bottle.

We offer individual filling equipment to complete line integration solutions. Our designs emphasize manufacture of high quality filling machines with remote and on-site support.

Liquid Filling Machines

Net Weight Liquid Filling Machine

Semi-Automatic Net Weight Liquid Filler

ZimaPack Inline Semi-Automatic

Liquid Filling Machine

ZimaPack offers a semi-automatic net weight liquid filling machine at an affordable price and small footprint. Semi-automatic models have the same technology as rotary & inline models and are great for lab use, R&D, testing, and low batch production runs.

ZimaPack net weight fillers are precise liquid fillers that reduce costly waste of product and production efficiency. Each machine can be customized to meet your needs. For example, the “Recipe and Production” video filling machine here was built for a Class 1 Div 1 Area and includes a nitrogen application, rinse station, rinsing tank reservoir and pump.

Here’s What They Do:

- The machine can dispense the substance into the container precisely, ensuring that each container will have the same amount of the substance.

- Entry-level filler that doesn’t sacrifice precise fills.

- Dispensing low-volume products and/or dangerous substances, such as chemicals, in a controlled manner makes it ideal for small runs or laboratory equipment as it results in fewer spills and accidents.

- Integration of an Optional Air/Water Rinser is possible.

Some of the products we fill (and cap): Solvents & Bondo, Isocyanates & Paint Products, Fresh Concentrated & Cold-Pressed Juices, Nutraceutical Supplements, Vitamin Oils, CBD Products, Agrochemical, Methanol & Ethanol Products, Organic Balms, Body Oils & Personal Care Products, Water, Barbeque Sauces, Dressings, Edible Oils and more.

ZimaPack Semi-Automatic Inline

Net Weight Filler Recipe & Production

ZimaPack Semi-Automatic Inline

Net Weight Filler and Air Rinse Testing

Fully Automatic Net Weight Liquid Filler

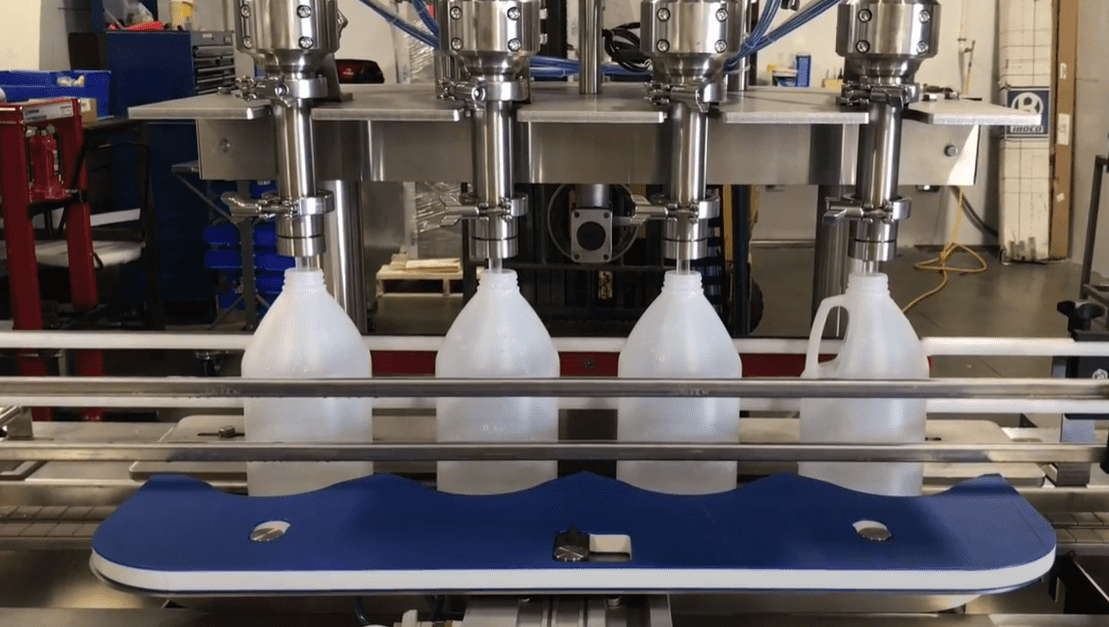

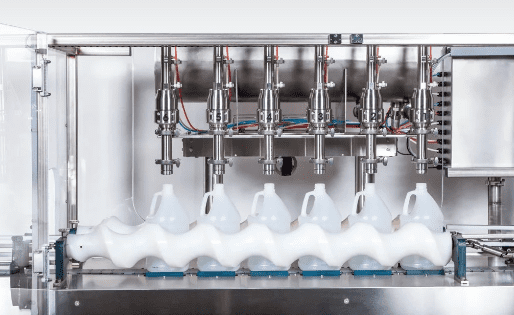

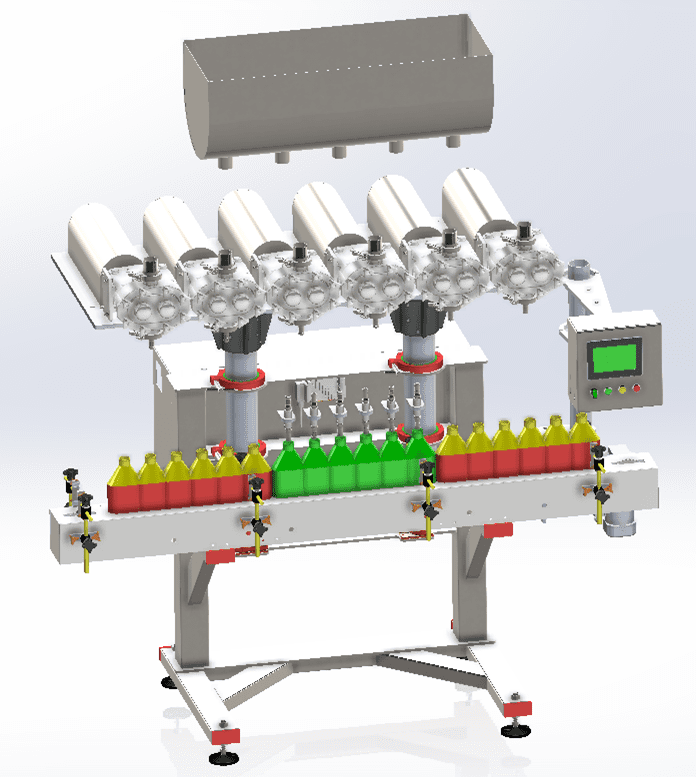

ZimaPack 4-Head Inline Fully Automatic

Net Weight Filler

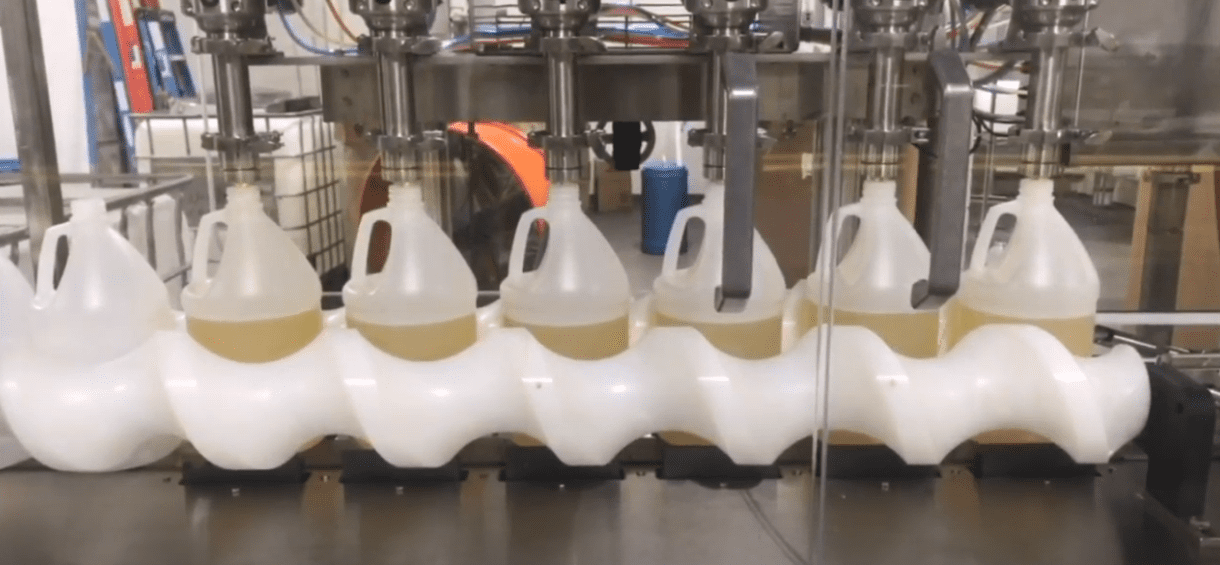

Our filling machines are designed to fill fluids, such as liquids, pastes, and creams, into bottles, jars, pails, cans, most rigid containers or those that can be held by the neck opening. In addition to being faster and more uniform than manual filling, filling machines also require fewer people to operate. As an additional benefit, it makes product contamination far less likely.

ZimaPack prides themselves in having bottle filling machines with the concept of filling by net weight. While volume changes with variables like temperature and barometric pressure, net weight remains constant.

Our machines create a perfect solution for controlling your product giveaway and costs. Here is how you can take advantage of our Filling Machines:

Custom Designed Nozzles. Our nozzles are created with ease of use, cleanliness, and longevity, perfect for filling rigid containers like bottles, spray bottles, detergent bottles (with or without handles), cans, pails, tubs, buckets, and so on. They are built in Stainless Steel 316L. The nozzle tips/plungers can be interchanged to accommodate a larger range of products and bottle openings. The nozzles do not penetrate the bottle during the filling process, preventing cross-contamination and ensuring overall cleanliness.

Versatility. The ZimaPack machine can accommodate a wide range of products designed with nozzles and nozzle tips, capping heads, tanks, special features, and quick tool-less bottle and cap change parts. We can make the machinery as adaptable as possible to meet a wide range of filling applications.

Clean In Place System. ZimaPack filling machines are equipped with a Clean In Place (CIP) system internally and externally. There is also an option to integrate foam cleaning systems. CIP recipes can be linked and saved with each product recipe. This way, you wouldn’t need to program this sequence each time, as some products may take longer to clean than others, maximizing efficiency and speed. There is an automatic trough that can collect the CIP solution/waste. Everything is piped for the internal CIP and external CIP so that you will have one collection point on the machine making it easy for changeovers.

ZimaPack 6-Head Inline Net Weight Filler

ZimaPack Inline Bottle Feeder

Capping Machine

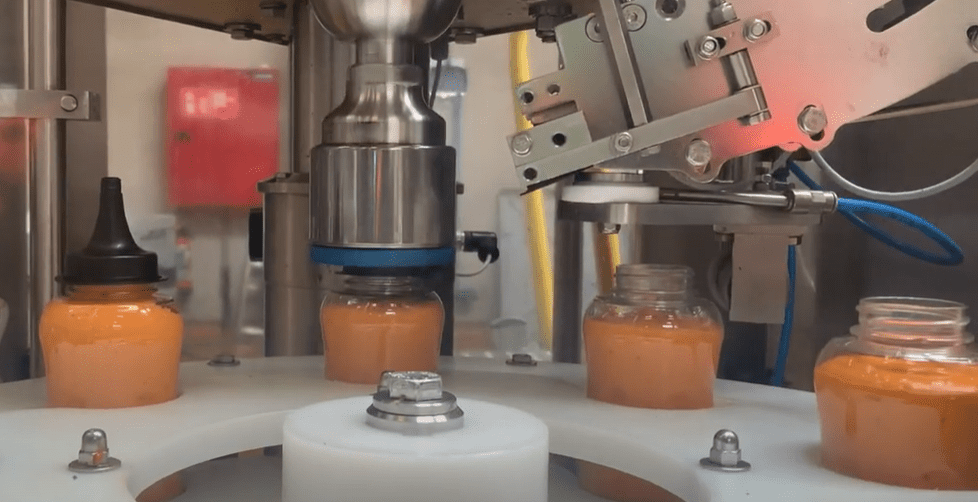

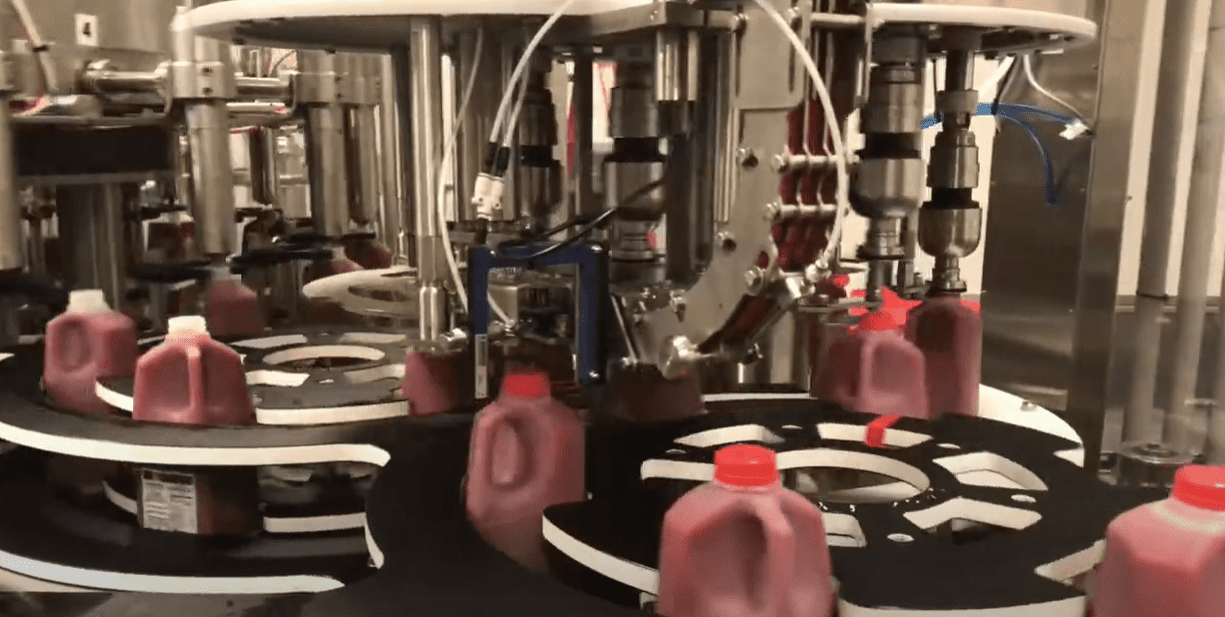

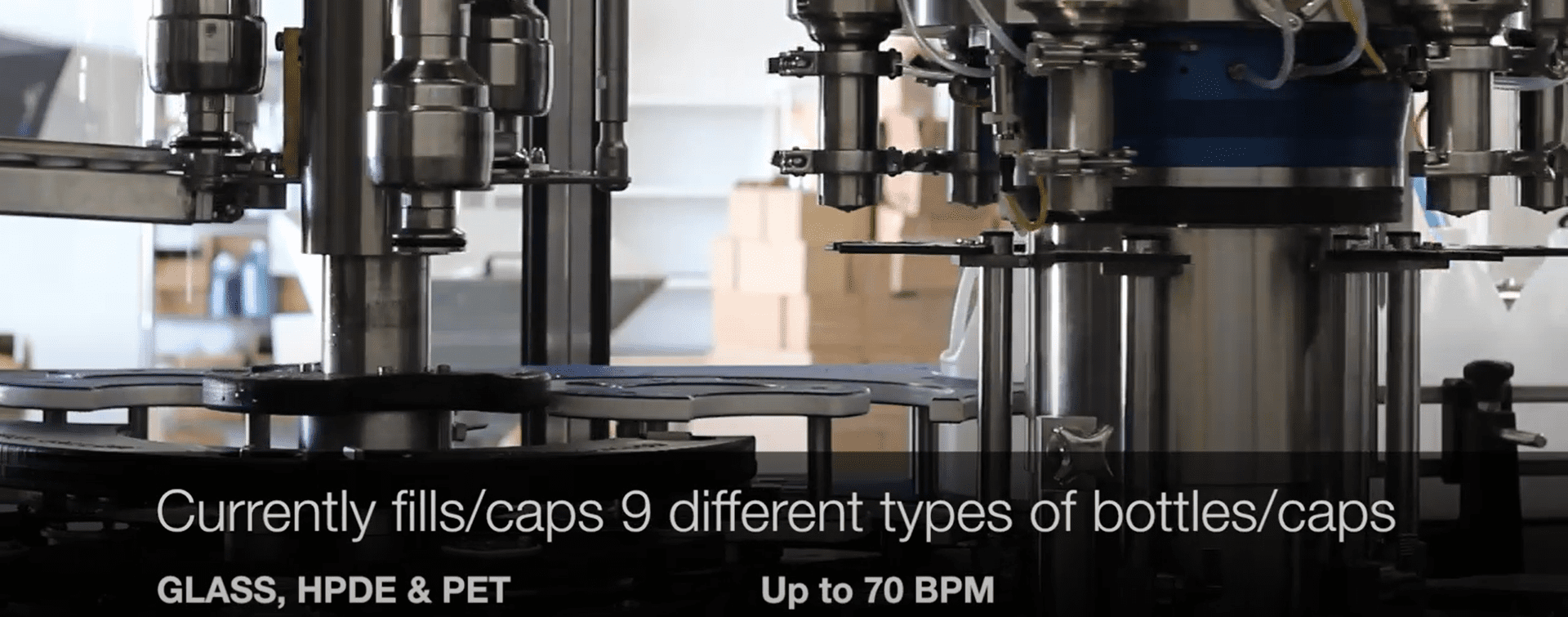

ZimaPack Automatic Rotary Pump Inserter Chuck Style Capping Machine

ZimaPack’s capping machines offer Semi-Automatic and Automatic Cappers. We can work with a wide range of containers and cap sizes, shapes, closures, various capping heads, specific chutes, sorters, and elevators. We only use Clutch-Style Capping Heads for our capping machines. Here is why:

Accomodates different types of caps – Allows for a very tight seal. Clutch-style capping heads are designed for various types of caps. They have a series of teeth that grip the cap and can be tightened or loosened to adjust the grip, making them ideal for use with both standard and non-standard caps. The Clutch-Style Capping heads allow for the torque to be adjusted for a perfect tight seal. It is essential because it means your product will be well-protected from the elements.

Why Choose Clutch Style Capping Heads? Clutch capping heads provide consistent and reliable capping without the fear of breakage, as with inline capping systems. It also allows a consistent and appropriate torque to be applied, ensuring a secure seal. With an inline capping system, there is no control of torque, which can cause inconsistencies in capping quality and potential breakage.

Types of Capping Heads. Our capping heads are the perfect way to seal your bottles quickly and precisely. We can build a Capping Machine to accommodate several different types of caps to promote versatility on your packaging line. Our experts can help you find the ideal capping head for your needs. We offer a solution for the following types of caps:

- Regular Flat Screw Caps

- ROPP Caps

- Press-On Caps

- Pump Caps

- Trigger Caps

- Flip-top Caps

- Sport and Push-pull Caps

- Dispenser Caps with or without pouring spouts

- Twist Caps

- Droppers (eye drops and dosing)

ZimaPack Rinsing, Filling & Capping Bottles

ZimaPack ROPP Capper - Monoblock

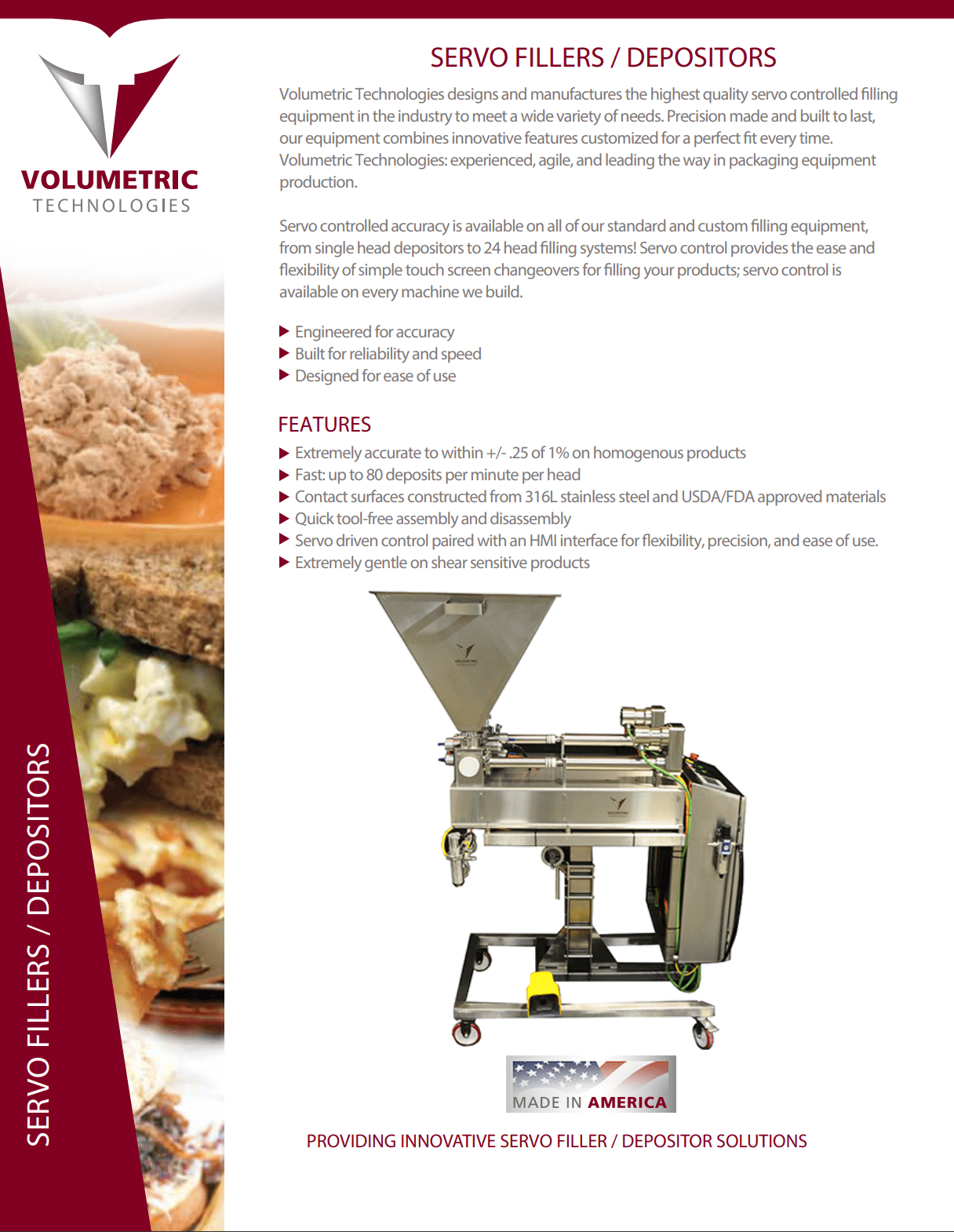

Volumetric Liquid Filling Machine

Servo Volumetric Piston Filler

AS&E Liquid Filling Machine

Bottle - Can - Glass - Plastic - Composite

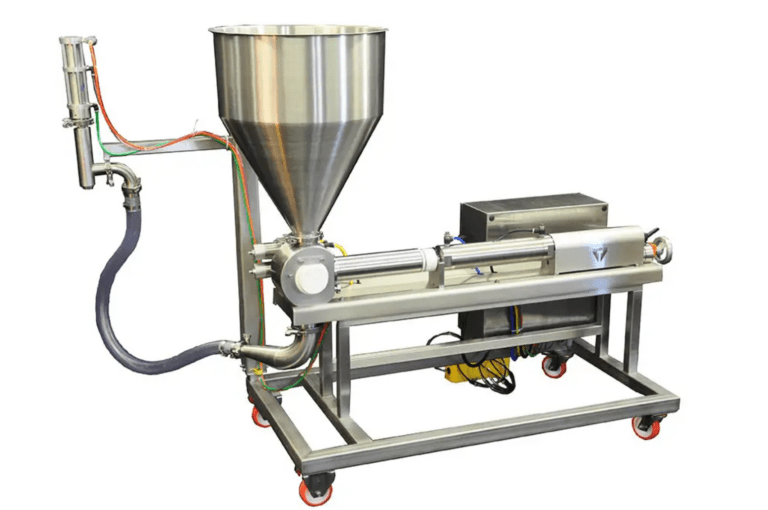

AS&E offers Servo Driven Positive Displacement bottle filling machines designed for high speed and accurate liquid filling. We can fill a range of liquid products from water to viscous along with a wide range of container styles and volumes. Each machine is custom designed to meet your desired line configuration and production rates.

The HMI allows operators to control package weight without calculations or subjectivity. We also include QD fittings for ease of sanitation and maintenance.

We offer many different configurations and mounting options. Such as: In-Line, Multi-Station, Multi-Lane, Column to Frame, Floor Stand, and Portable. These systems can be used in stand alone applications or integrated into automatic conveying lines and packaging machines.

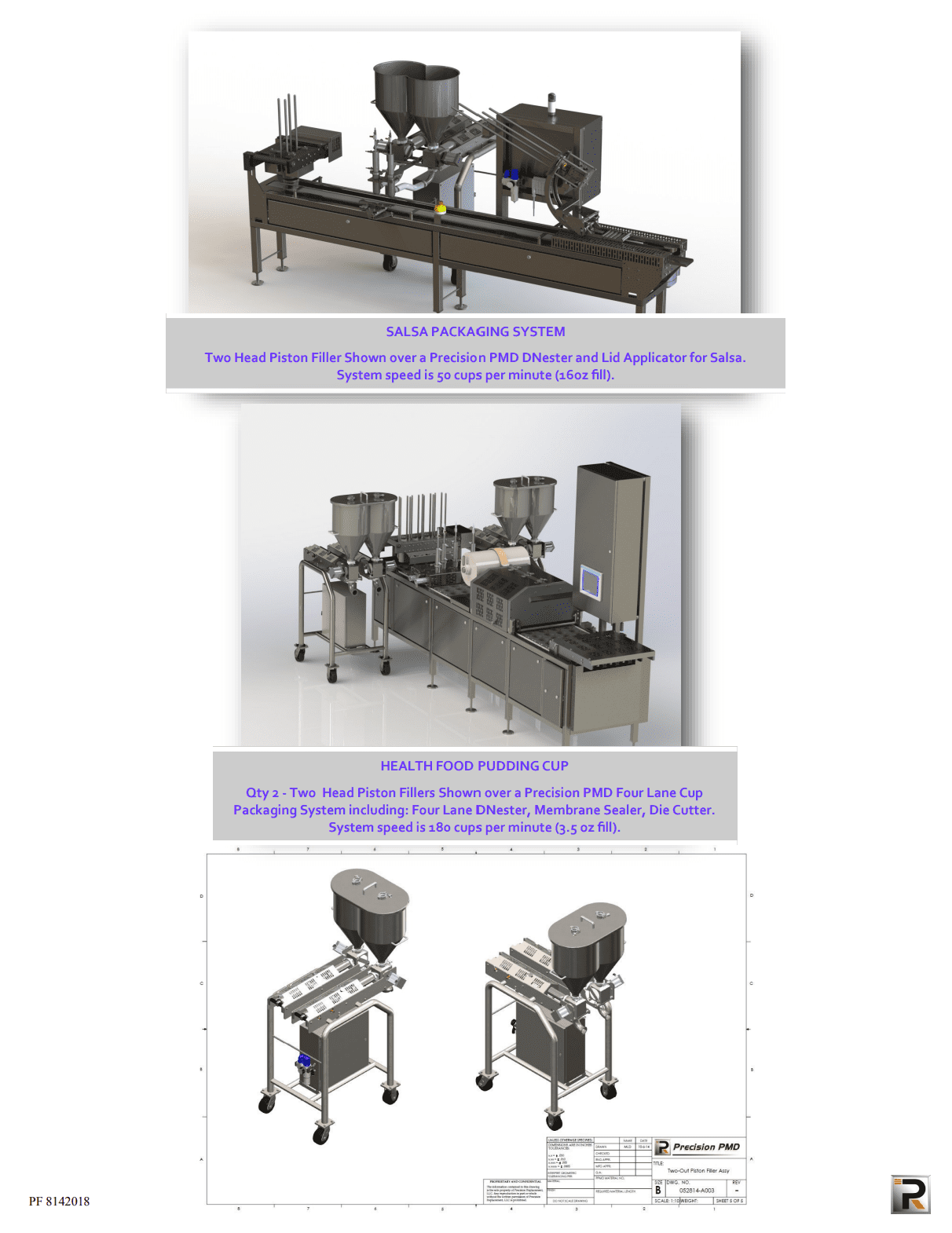

Piston Filler / Depositor

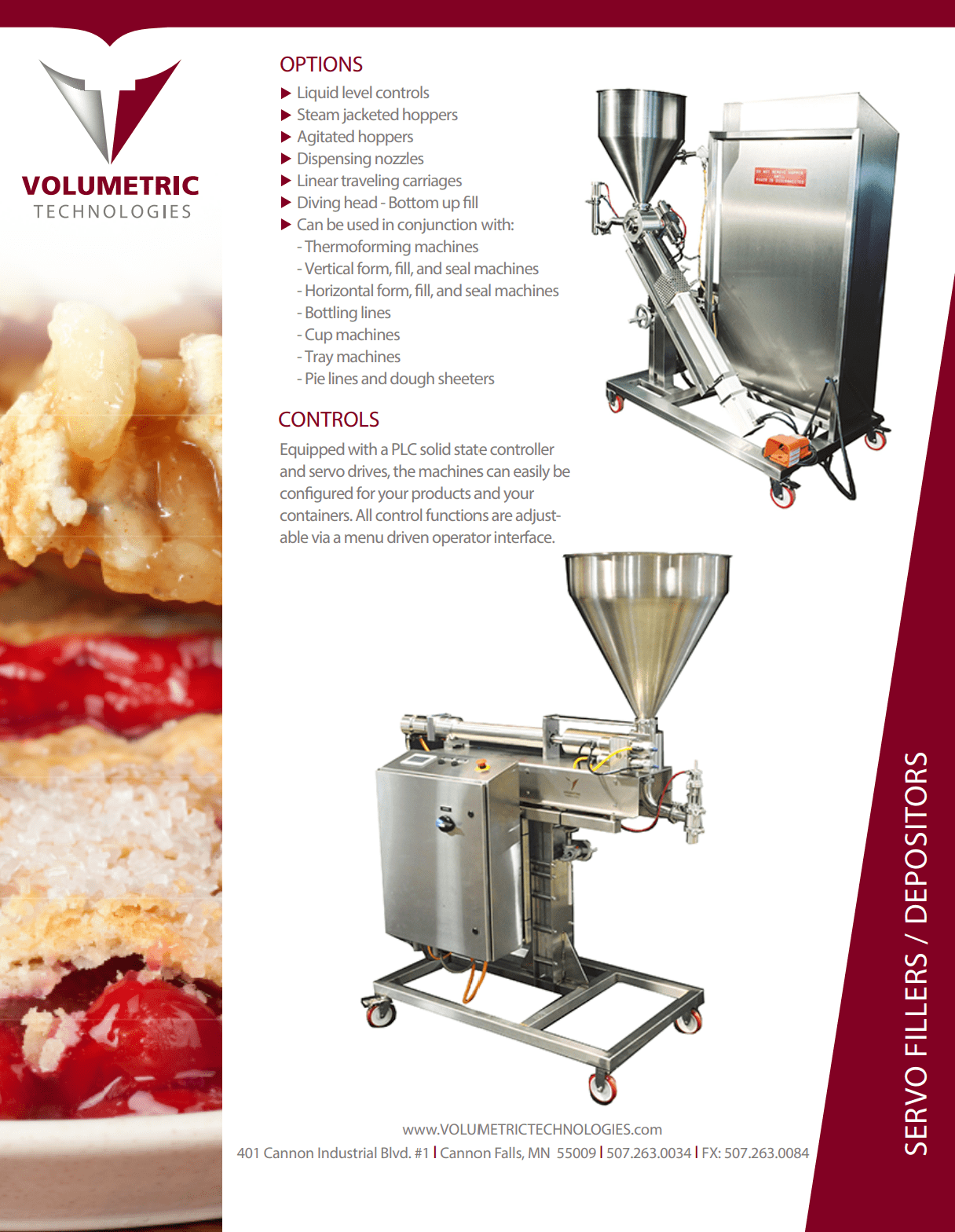

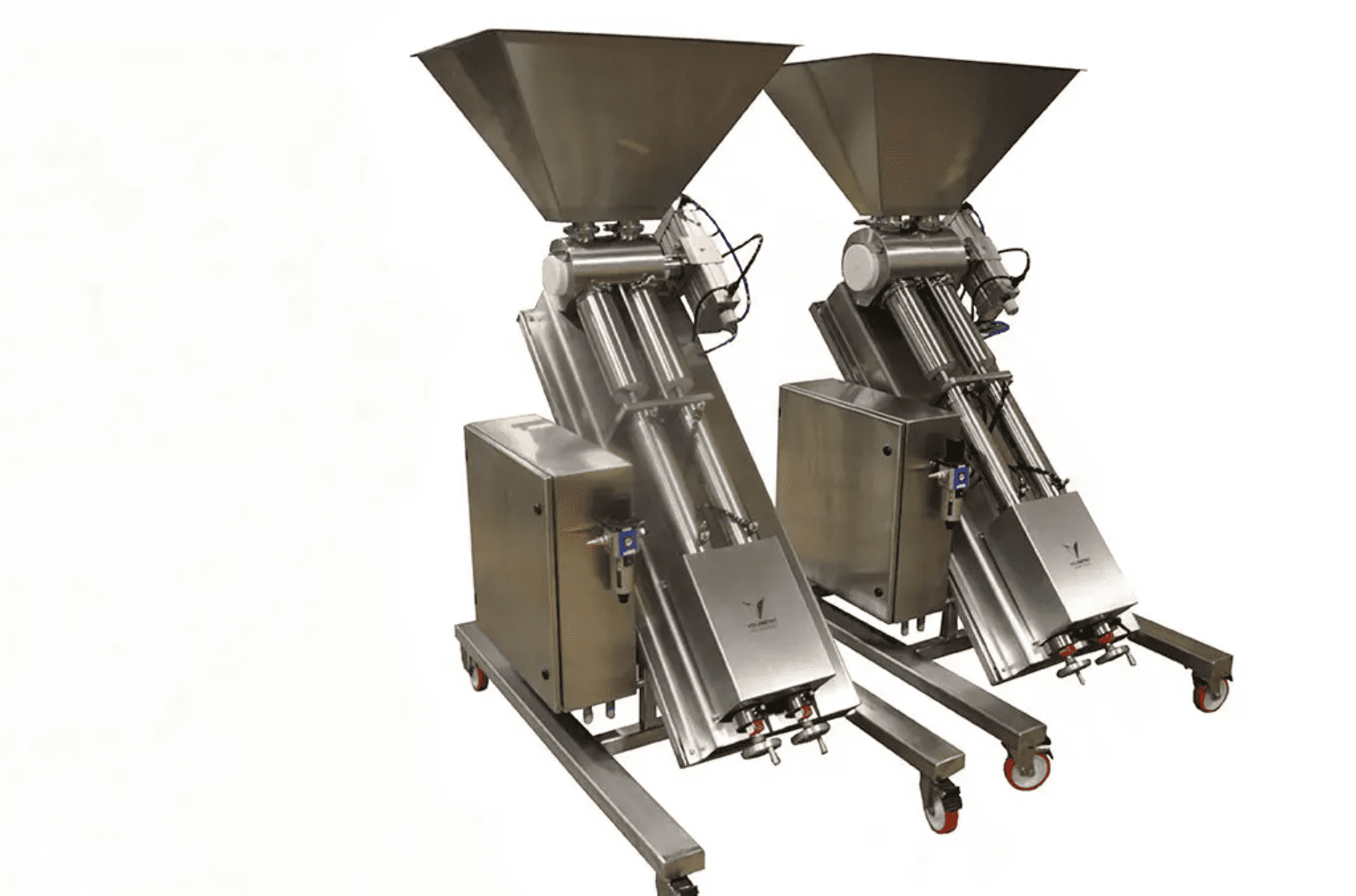

Our piston fillers & piston depositors all start with our innovative product pathway that allows our Horizontal and Incline Series machines to fill and deposit your products at higher speeds. Our piston filler machines provide clean drip-free depositing and adds precision in your product packaging lines.

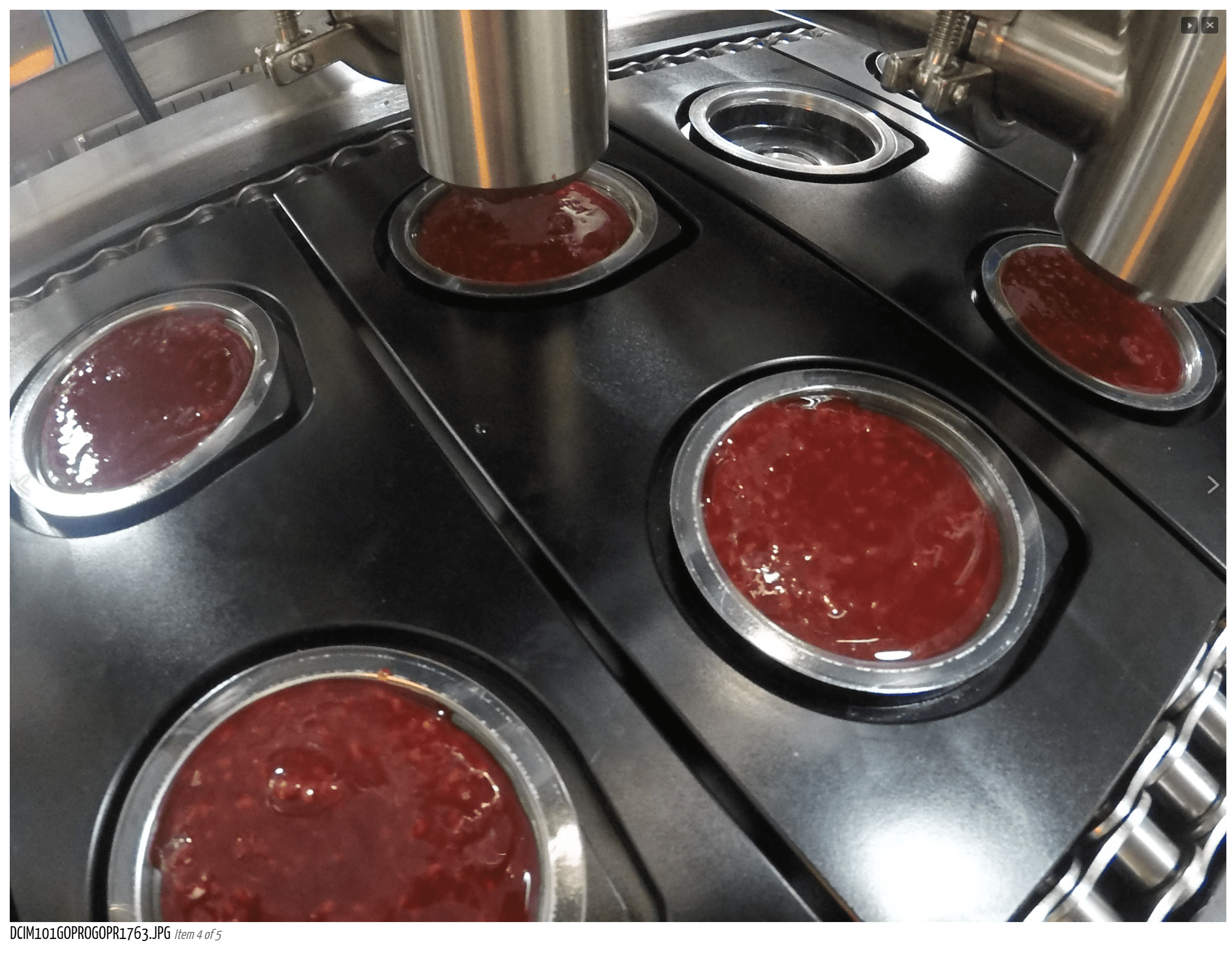

We configured our piston fillers to deposit accurate amounts of sauces, stews, batters, meat/sauce mixtures, and pastes every single time. Slips, drips, and container overflows may be common in food filling lines, but not when you use piston fillers from Volumetric Technologies.

We offer piston, servo depositors and filling machine models with single head to 24 head liquid filling systems. These are engineered for accuracy, built for reliability, speed, and designed for ease of use. These machines can be used in conjunction with the following machine systems: Thermoforming, VFFS, HFFS, Bottling lines, Cup, Tray, bowl, Pie lines and Dough Sheeters.

Features include: Fillers are extremely accurate (up to +/- .25 of 1%) with up to 80 deposits per minute, per head. Product contact surfaces are constructed of 316L stainless steel and USDA/FDA approved materials. Quick tool-free changeover for assembly and disassembly. Gentle filling on shear sensitive products.

Piston Filler / Depositor Integrations

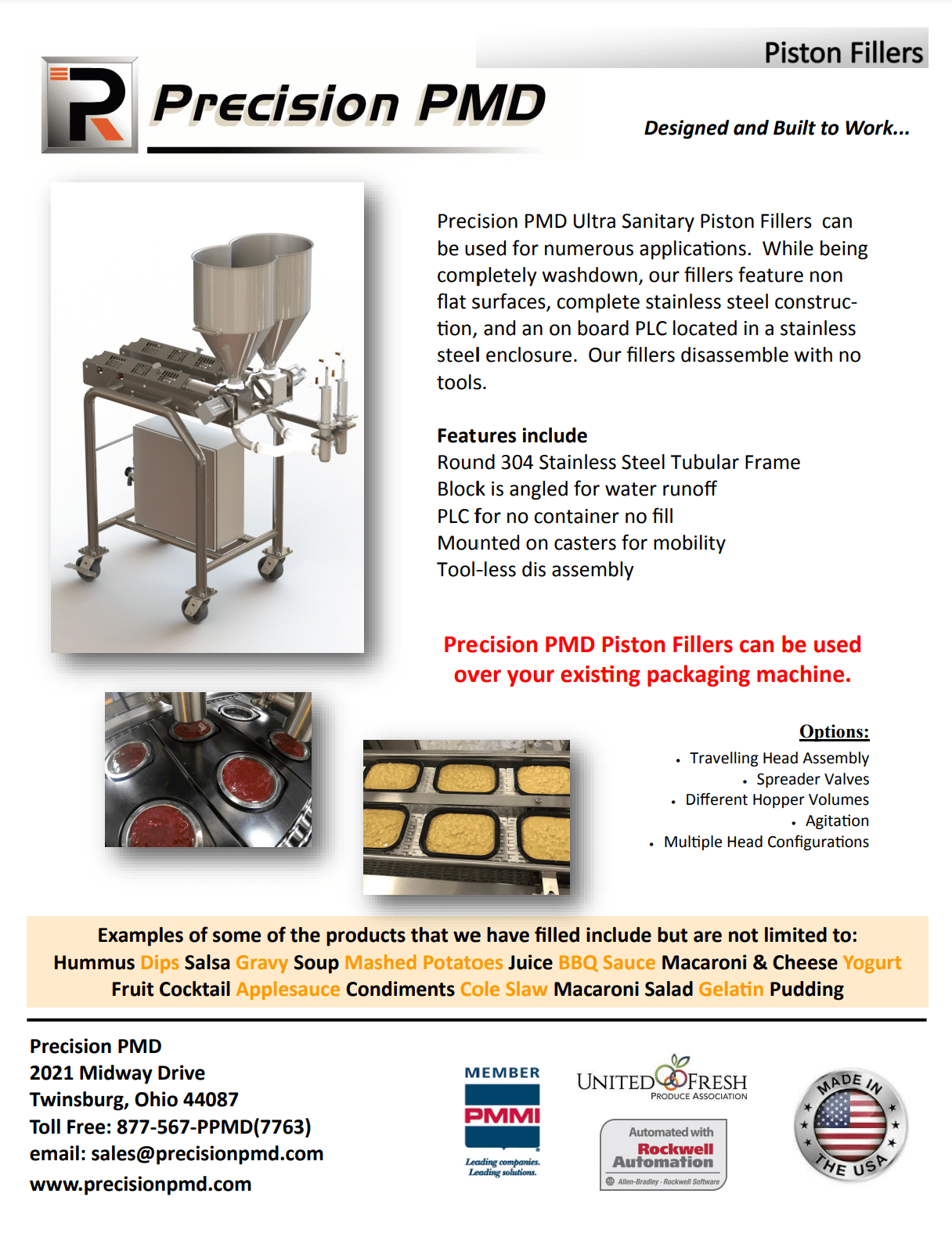

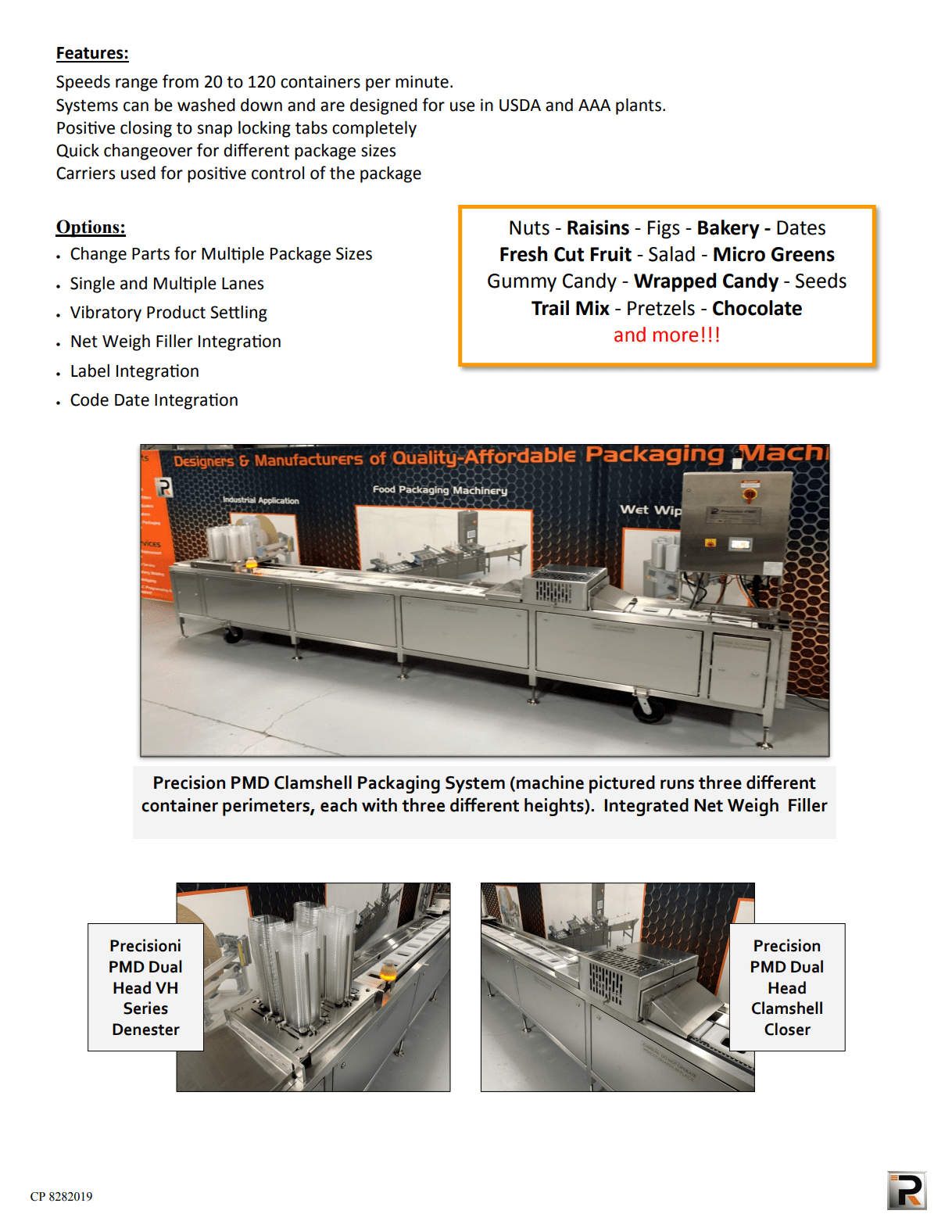

Precision PMD Liquid Filling Machines

Servo - Piston - Lobe Pumps

We manufacture a variety of fillers each designed for a specific purpose. Piston Filler (PF Series), Rotary Pump Fillers (LP Series) for pumpable products, Horizontal Volumetric Fillers (RVF Series)and Vertical Volumetric Fillers (Roto-Fill Series) for dry and IQF free flowing products.

Our fillers are made of stainless steel and food grade plastic, and are fully washdown capable. With GMP (Good Manufacturing Practices) in mind, our machinery can be used in USDA, FDA, and AAA facilities.

Our fillers have been designed to not only take up less space than our competitors, but are designed for today’s stringent sanitation requirements and along with an ease of operation and maintenance. All fillers disassemble in less than 2 minutes. We offer from single to multi-lane applications, intermittent and continuous motion, Precision PMD fillers are designed and built to work.