Tubular Conveyors

Install, Mobile, and Custom Configurations

Convey free-flowing & non-free-flowing bulk materials including products that pack, cake, plug or smear in other conveyors – with no separation of blends – at any angle, through small holes in walls or ceilings.

Screw conveyors are also highly effective for handling fragile or brittle products that tend to break or crumble from the friction, crushing, grinding, pressure, or impact that can occur in other conveyors.

Products ideally suited to the special capabilities of a Flexicon screw conveyor (BEV-CON) range from sub-micron powders to large pellets and include: Chemicals, Foods, Pharmaceuticals and Cosmetics.

Tubular Conveyor Systems

Tubular Conveyor

Flexible Screw Conveyor

Flexicon Flexible Screw Conveyor

Flexible Screw Conveyors offer efficiency and versatility, conveying bulk materials ranging from large pellets to sub-micron powders – both free-flowing and non-free-flowing – with no separation of blended products.

All Flexicon flexible screw conveyors are available on caster-mounted frames with conveyor support masts for in-plant mobility, reducing the need for multiple stationary units.

Both mobile and stationary units are readily customized using interchangeable screws, conveyor tubes, drive motors, sensors, controllers, and other components to satisfy the most diverse and demanding end-use requirements.

Pnuematic Conveyor

Flexicon Pneumatic Conveyor

(Pressure & Vacuum)

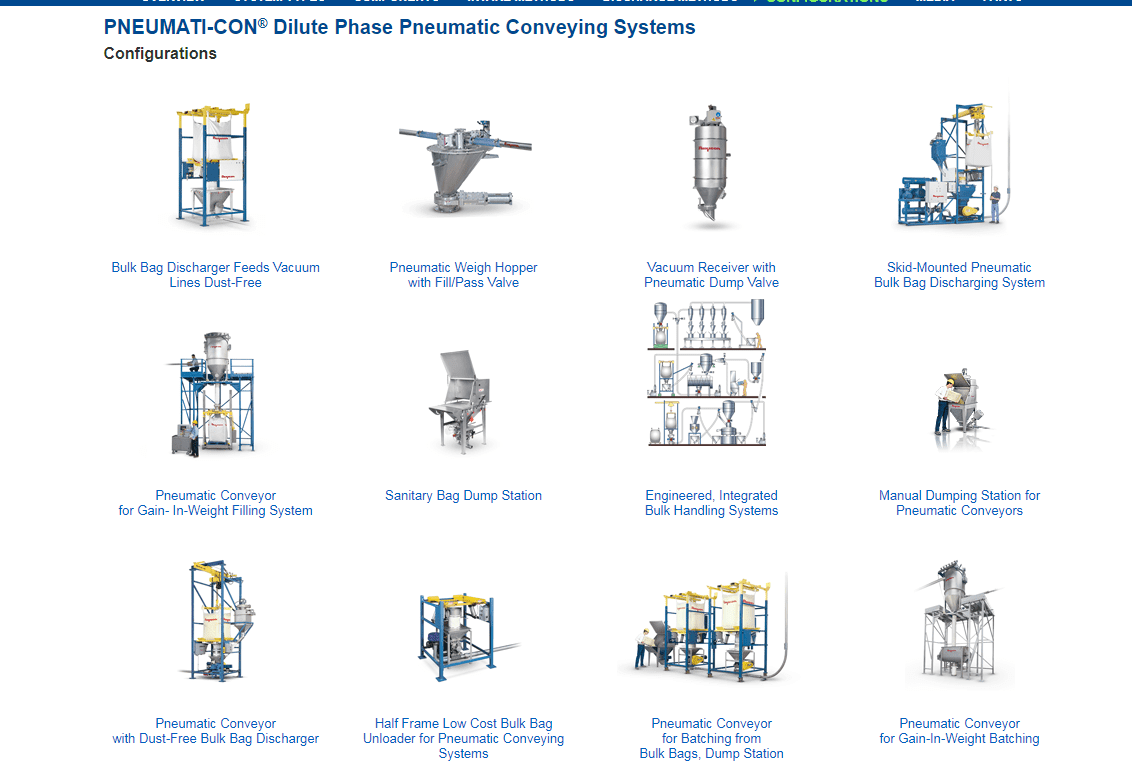

Flexicon’s PNEUMATI-CON dilute phase pneumatic conveying systems range from single-point “up-and-in” installations to cross-plant systems with multiple pick-up and discharge points, and automated controls, satisfying an exceptionally wide range of bulk conveying applications. All are custom-engineered and fully integrated with other Flexicon equipment and systems, and your new or existing process.

PNEUMATI-CON conveying systems move bulk materials suspended in an air stream that is introduced by a positive pressure blower upstream of material intake points, or by a vacuum pump that removes air from the system downstream of material discharge points. Material is separated from the conveying air at the use point, then discharged on a batch basis via a butterfly or slide gate valves, or continuously via rotary airlock valves.

These systems fully evacuate the vessel being discharged and the conveyor line itself, minimizing cross-contamination of multi-ingredient systems. We can convey a capacity range from several pounds to tens of tons per hour, feeding any destination from small packaging lines to silos and railcars.

Totally enclosed and dust-free, a PNEUMATI-CON conveying system prevents contamination of the product and plant environment, allowing safe transfer of contamination-sensitive materials including dusty and hazardous products.

Drag Conveyor

Flexicon Flexi-Disc

Drag Conveyor Systems

Flexicon’s PNEUMATI-CON dilute phase pneumatic conveying systems range from single-point “up-and-in” installations to cross-plant systems with multiple pick-up and discharge points, and automated controls, satisfying an exceptionally wide range of bulk conveying applications. All are custom-engineered and fully integrated with other Flexicon equipment and systems, and your new or existing process.

This design allows single or multiple inlets and outlets, and the routing of conveyor tubing horizontally, vertically or at any angle, through small holes in walls or the ceilings. Because components are modular, inlets and outlets can be added, removed, or relocated, and the circuit lengthened, shortened or re-routed as needs change.

In addition, to reversing direction of the cable/disc assembly, the drive system can be equipped with a cone discharge housing to serve as the final point in a multi-discharge point system or as the only point in a system.

Totally enclosed and dust-free, a PNEUMATI-CON conveying system prevents contamination of the product and plant environment, allowing safe transfer of contamination-sensitive materials including dusty and hazardous products.

Quick Ship Flexible Screw Conveyor

Flexicon Quick Ship Flexible Screw Conveyor

Quick Ship Flexible Screw Conveyors are designed for the most typical or common applications and deliverable in a couple weeks, not months, following receipt of order and once payment terms are met.

Standard Quick Ship Equipment includes: Screw length range from 10′ to 40′ and a tube diameter range from 2.125″ to 4.5″ OD., stainless steel floor hopper, TEFC or wash-down duty motor, 45 or 90 degree discharge adapters, UL Listed control panel, NEMA 4, carbon steel construction with durable industrial finish for non-product contact and stainless steel for product contact surfaces.

Available Options include: vibratory hopper flow promotion, hopper cover with un-flanged inlet port, hopper screen, low level sensor, NEMA 4 and a few others.