Incline Conveyors

Elevate Product to the Key Processes on Your Food Processing Lines

These conveyors provide optimal product handling wheteher your bulk product is wet or dry, sticky or abrasive, buckets and incline conveyors gently lift it throughout your processing line with minimal degradation or loss.

Incline conveyor systems are designed to be integration-ready with flexible configurations and a low-maintenance sanitary design. In addition, we manufacture stairs and platforms to support the entire elevated process.

We offer various models such as mix/blend systems, weigher feeders, to packaging or a platform, in a minimal footprint.

Incline Conveyor Systems

Bucket Elevator Conveyor

Bucket Elevator

The Bucket Elevator is a time-trusted , long-lasting conveying solution that vertically lifts high volumes of product to the key processes on your food conveyor processing line in a small footprint. Take your production to new heights with our Bucket Elevator.

Flexible configurations include: Horizontal, S, C, or Z-shape and available in a range capacities (135 – 3,780 cubic feet per hour), frames, bucket types and sizes to fit your application. We offer bucket widths from 6″- 48″ (152-1,219mm) and easy access buckets with quick, tool-less changeouts and are available with multiple discharges for additional layout flexibility.

Optimal product handling is achieved with overlapping buckets that contain product during transport, ensuring no degradation, breakage, or spillage and maintaining blend integrity.

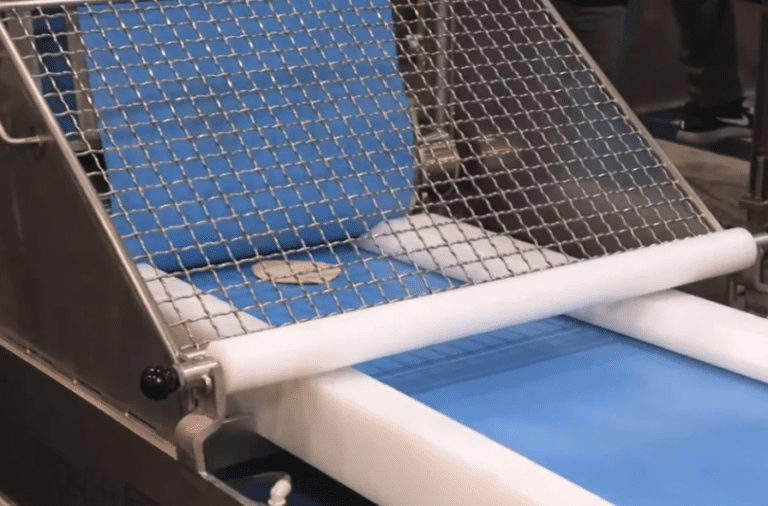

Incline Belt Conveyor

Inclined Belt Conveyor

Elevator conveyors are a positive drive, Vertical Lift Conveyor. We lift not just dough, rather a variety of products to the next step in your process with minimal product waste in a compact footprint. Where you also can quickly adjust the pivot point to accommodate multiple products.

PFi’s PURlift is a dual “sandwich” belt lift conveyor that vertically lifts product up to up to 90 degrees. Designed with a self-tracking positive drive belt and belt scrapers to ensure consistent flow and no product waste, even on sticky products like dough, peanut butter, or meat and green beans.

We engineered an automatic infeed, pneumatic belt tensioning, and adjustable belt hold to provide dependable, efficient, and quite operation. Sanitation is more efficient with caster footings to move on and off the line quickly. Our food grade sanitary design incorporates an open frame and belt lifts for tool-less washdowns.

IAMHEADING

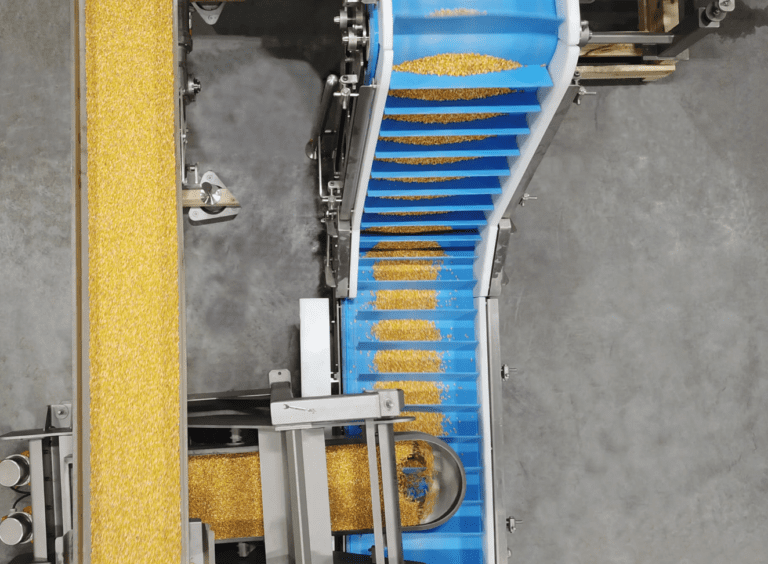

Elevator Conveyor

A Conveyor Belt Elevator will connect the key processes on your food processing line and packaging lines. We elevate product to equipment like mix/blend systems, scales and packaging, or a mezzanine, in a minimal footprint.

They are available in horizontal, incline, and z-shape configurations to fit your application. We provide conveying angles from 5 to 90 degrees, operate up to 150 FPM Maximum Speed, and up to 72″ maximum width.

Some of our features include a positive drive system, self-tracking belts to keep production running safely, consistently, and without product loss. In addition, an open frame design with easy pivoting side guides and belt lifts for tool-less washdown.

Some of the options include a washdown or RTE sanitation levels, belt return CIP sprayers, catch/drip pans, infeed hopper, and custom discharge chutes. We offer belt styles ranging from positive drive, thermoplastic (TPE, TPU), modular, straight, angled or scoop cleats, and corrugated sidewalls.

Accumulation Conveyors

Accumulation Conveyors

Temporary Storage Conveyors are available in a wide range of storage capacities and buffer temporary stoppages in order to standardize discharge flow to avoid disruptions downstream.

These Storage Conveyors are designed to temporarily accumulate and store 500 – 70,000 lbs. of product in a stainless steel bin, then when product is called for, uses belt conveyors to discharge it to the next process.

These maintain product integrity with gentle loading, ‘first-in, first-out’ design, can be integrated with a range of infeed and outfeed options, including elevators, vibratory feeders, and more. We offer stainless steel construction, sanitary design, and choice of contact surfaces for optimal cleaning.

Some of our typical options include: custom infeed and outfeed configurations, surface finishes – smooth or rigidized, rake or rotating fingers to move product, and multiple belt offerings.