Industrial Conveyor Belt Systems

Belt Conveyor Systems Give Food Processors Immediate Value

Belt conveyors have been the standard, modular solutions to connect your proceesing line and move your product. Equipment is designed for gentle handling and tight transfers to avoid degradation and breaks. We collaborate with OEM’s and engineering firms to seamlessly link your key machines and processes.

Every belt conveyor system solution is custom configured and easily integrated for you. We offer horizontal, incline, and curved conveyors that perform a range of applications. Choose the specs, belt types, sanitary levels, and options that will satisfy your expectations.

We put maintenance and sanitation at the forefront of our equipment design. We configure our conveying and handling solutions to be easily accessible to clean and maintain.

Types of Belt Conveyor Systems

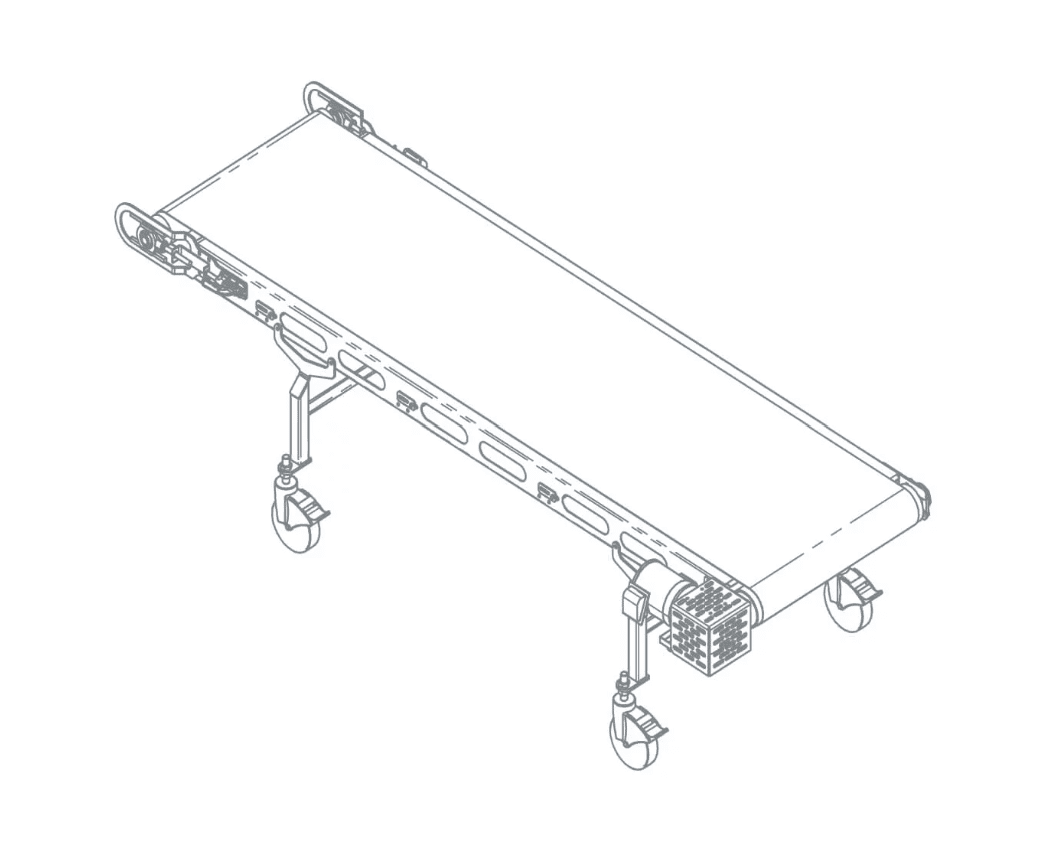

Flat Belt Conveyor

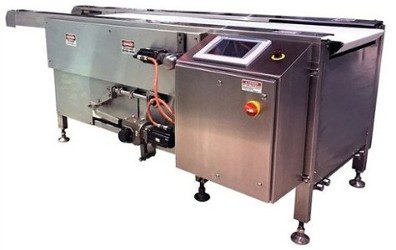

Chicago MetalCraft Flat Belt Conveyors

Chicago Metal Craft is a proven conveyor belt manufacturer that engineers their belt conveyors to be simple, reliable, easy to use and clean. We offer portable belt conveyors systems, modular belt conveyor systems, plastic belt conveyor systems, and all belt conveyors are stainless steel construction with hygienic design to meet USDA requirements, as well as easy disassembly for sanitation washdown.

We offer a variety of food grade conveyor belt types and food processing conveyor belts made from urethane material. Additionally, we offer options such as variable speed drives with mounted adjustable locking casters, and the availability of quick ship orders depending on complexity.

Horizontal Belt Conveyor

PFI Conveyors Horizontal Belt Conveyor

Why Horizontal Belt Conveyor. Horizontal Belt Conveyors are a simple, modular solution to fit throughout your processing line to move your food products reliably and safely.

Dependable, Simple Operation. A simple solution to convey your food product long distances throughout your plant.

Flexible Configurations. Available in the dimensions you need to connect your key processes, and with a range of options and belts precisely for your application.

Sanitary Design. Featuring a food grade sanitary design, a stainless steel frame and optional tool-less belt removal to keep sanitation quick yet thorough. Options like positive drive, belt lifts, and CIP systems are available.

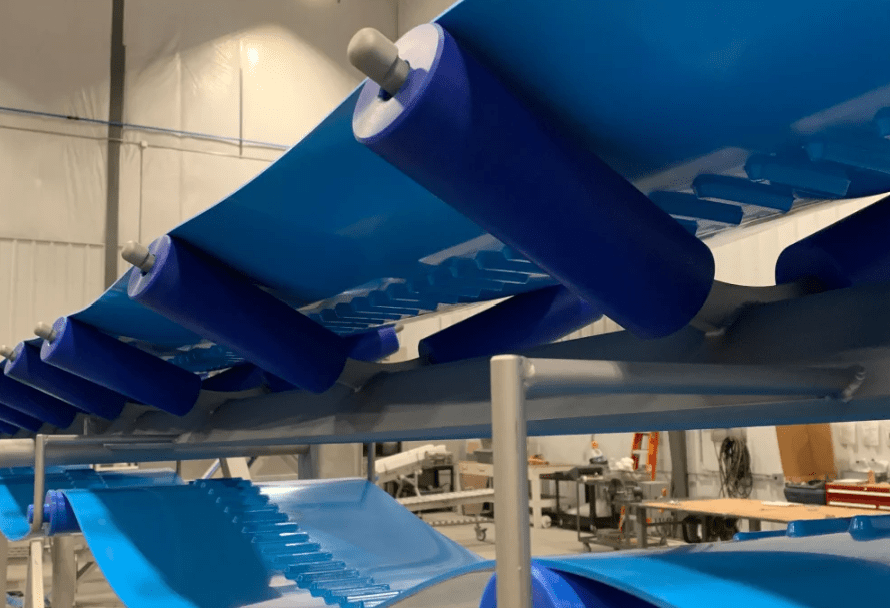

Trough Conveyor

PFI Trough Belt Conveyor

Why Troughveyor. The Troughveyor conveys loose, bulk food products reliably throughout your food processing line with positive drive technology and rollers or rails that center product – ensuring dependable operation and no loss.

Dependable High-Volume Product Control. Stress-free loose product conveying without spillage and product loss – even at high rates and long distances.

Flexible Configurations. Available horizontal or incline operation, center or end driven, and pneumatic or manual take ups to fit a range of applications.

Sanitary and Maintenance Friendly. Featuring a food grade sanitary design, open frame, no fixed sidewalls or guards, belt lifts, and cantilevered belt for fast, tool-less washdown and belt changes.

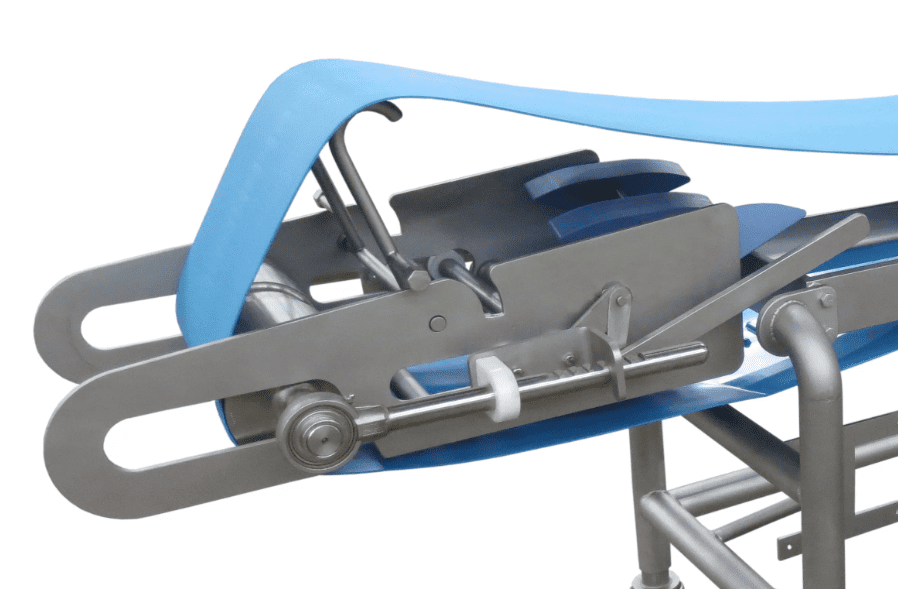

Retractable Conveyor

PFI Retractable Conveyor

The Retractable Belt Conveyor has multiple applications on your food processing line in one machine, moving your product 90 degrees to the next process with gentle handling and accurate alignment.

It is a food-grade sanitary design with a positive drive system and easily removable guarding for optimal sanitation. These belt conveyors will gently transfer and deposit products into rows or stacks, position, load, or reject products between key processes in your production line.

Tight infeed and outfeed transfers ensure product orientation and integrity with no damage or loss in gaps. We provide tight product transfers with 5/8″ or 7/8″ rolling nose bars for smooth, damage-free transitions.

Available conveyor belt widths can be up to 84″, and belt conveyor length is dependent upon application. Retracting cycle speeds can be up to 150 cycles per minute and are offered with the following belt types: thermoplastic, modular, wire, and fabric reinforced.

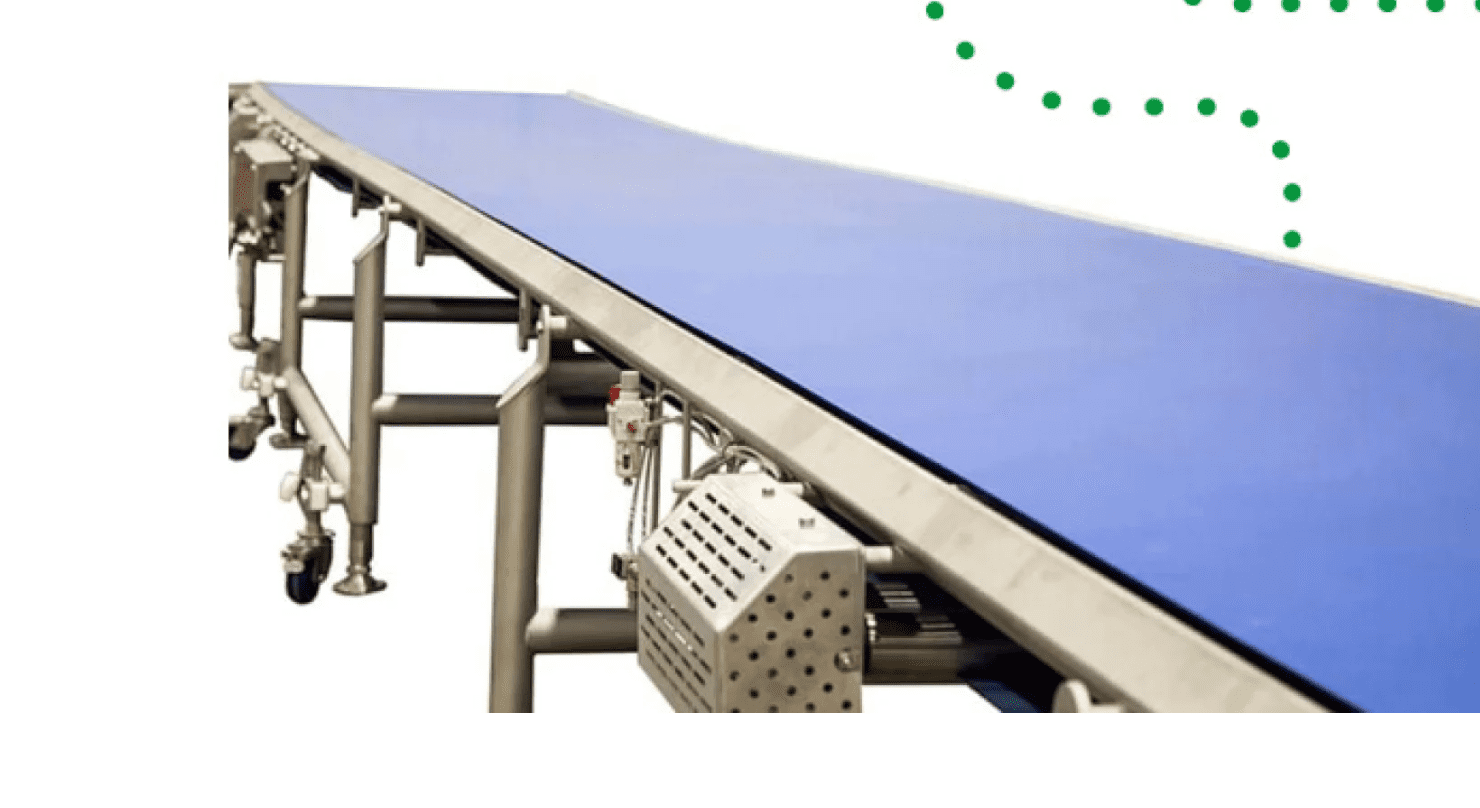

Curved Conveyor

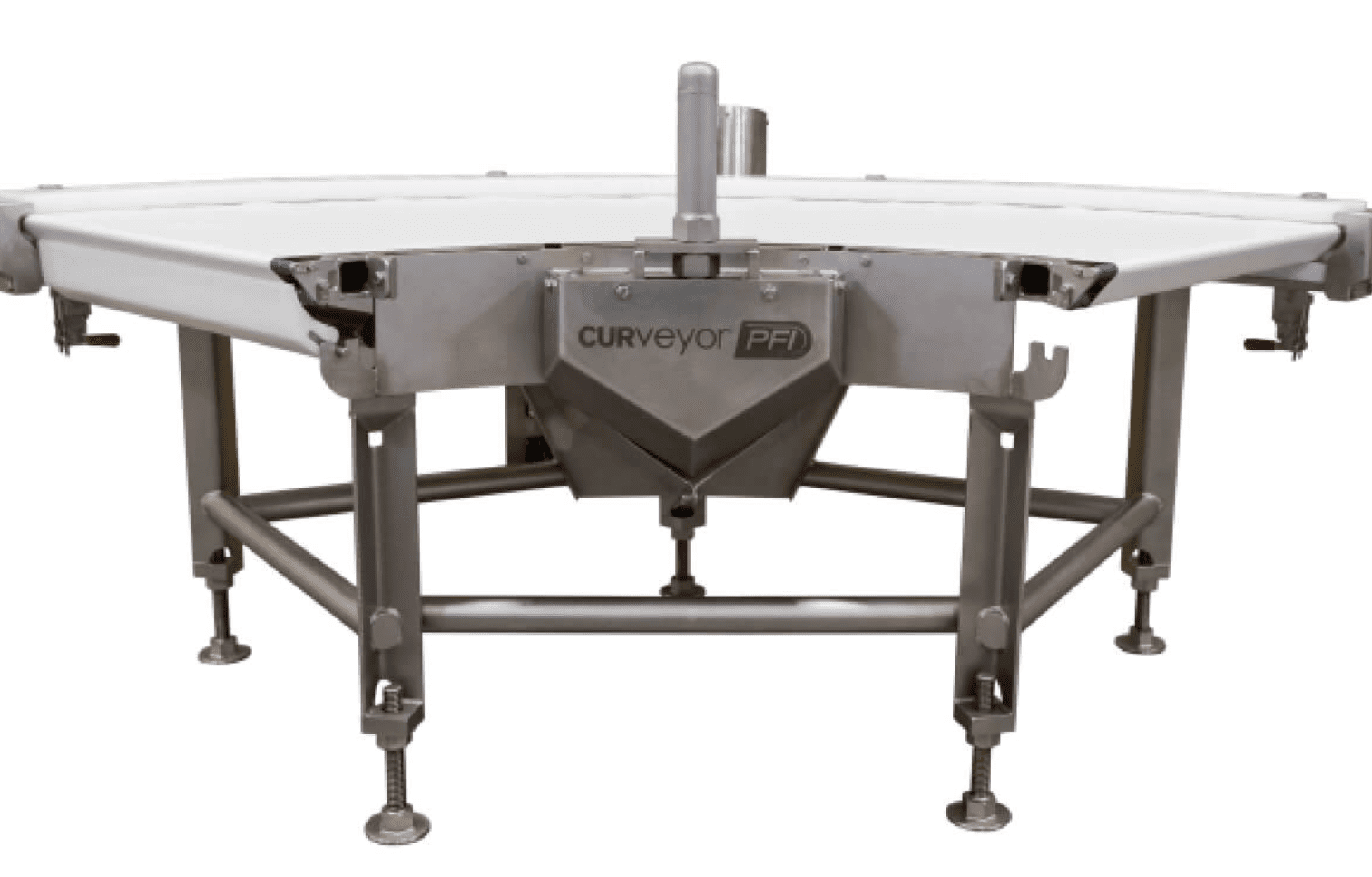

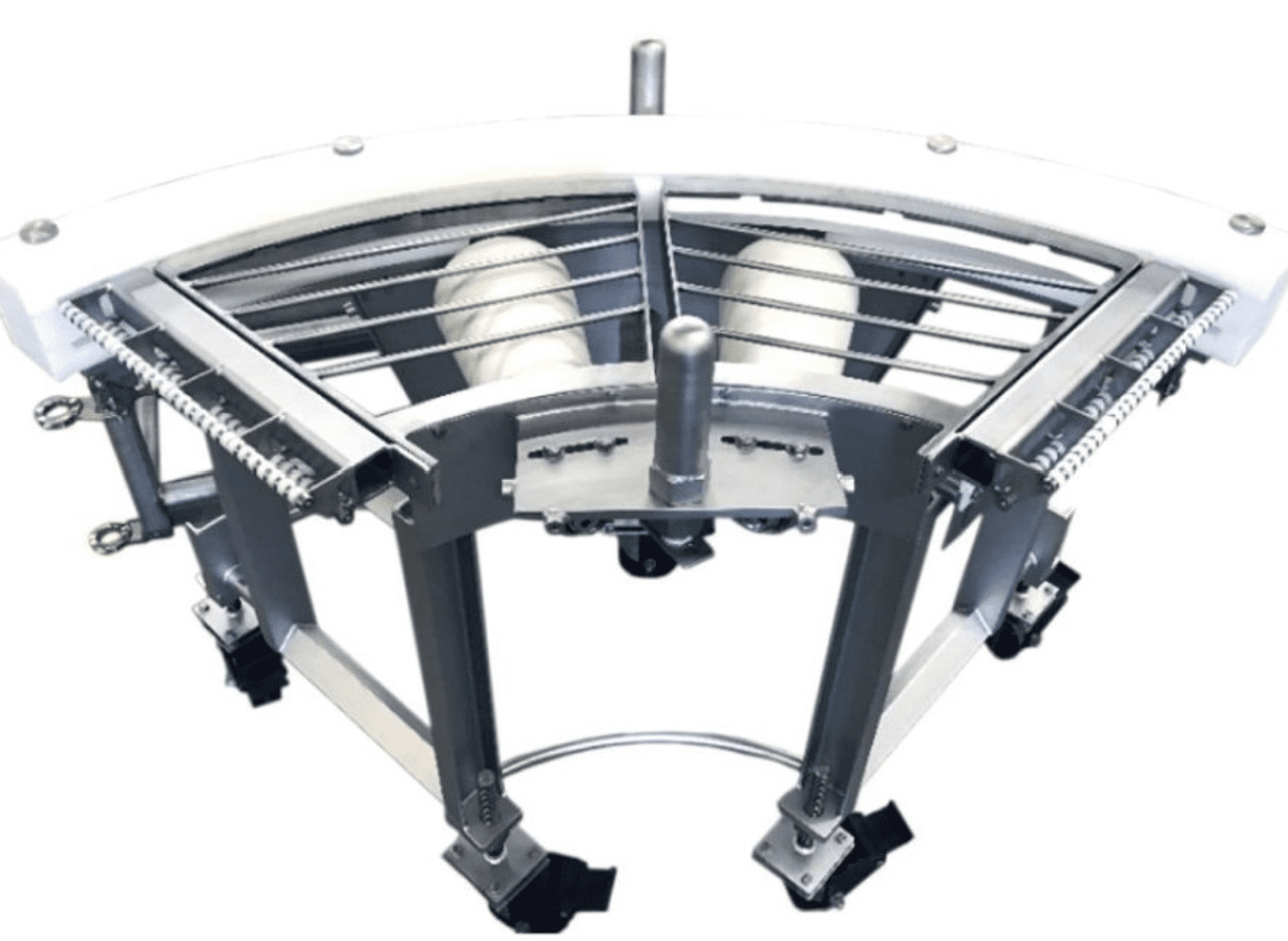

PFI Curved Belt Conveyor

Why Curveyor. The Curveyor connects the key processes on your food processing line, regardless of the obstruction, and maintains product integrity. Overcome any configuration conundrums with the Curveyor.

Flexible Configurations. Available in 30-180 degree turn radius and various widths, with bi-directional product flow.

Damage-Free Conveying. Small diameter infeed and outfeed rolling nose bars transfer product to your equipment without gaps or damage.

Sanitation & Maintenance Friendly. Featuring an open-frame design, power drive belt, and 30 minute belt changes with no chains or rubber bands.

Roller Conveyor

Chicago MetalCraft

Roller Conveyor

A CMC motorized roller conveyor or gravity roller conveyor are designed for portable or fixed installation to feed various production lines. We offer a design for ease of operation, reliablity, mantenance freindly, sanitation washdown and hygienic design to meet USDA requirements. Stainless steel, fully welded construction, easy disassembly for maintenance and sanitation, and locking casters are included. We offer custom and standard sizes built in 10′ or custom lengths and food-grade plastic rollers 22″ in width.