Primary Product Packaging Equipment

At FES, we believe in forging lasting B2B relationships. We supply product packaging equipment in the Midwest and nationwide for CPG’s, contract packaging, regional brands, and start-ups. Our products combine speed, innovation, and flexibility while providing greater value for companies facing increased competitive pressures.

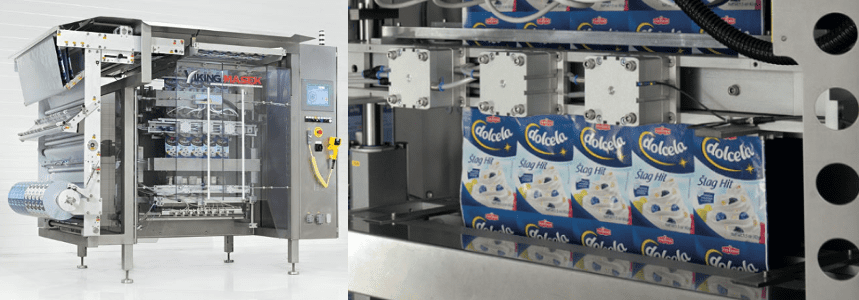

Vertical Form Fill Seal

Viking Masek Intermittent & Continuous Motion

- Accurate speed and repeatability for food and non-food items, liquids, and fractional packs

- No-tool changeover

- Operates accurately even in wet or dusty environments

- Made to meet your specifications for bag styles, printing, and cartoning

- Modular designs meet a wide variety of specifications.

- Modelas range from the VFFS Velocity, the world’s fastest continuous motion vertical form fill seal packaging machine to the VFFS Solitare, which is perfect for cheese or bulk packaging

- Packages liquids, solids, bulky or sticky items with speed and precision

Viking Masek Stick Packaging

- Convenient, single-serve, on-the-go packaging

- Perfect for drink mixes, legal cannabis products, and pharmaceutical powders

- Available changeover kits

- Multiple stick sizes can be packaged on a single stick packaging machine

- Various levels of industry applications, including entry-level to 20-lane ST1200

- Options include tear notches, seal patterns and shapes, static elimination, embossing

- Available with IQ/OQ construction

Viking Masek Sachet Packaging

- Four-side-sealed sachet offers ultimate convenience packaging for industries that require powders, liquids, and capsules

- Packages up to ten lanes at once

- Accommodates different bag options, including tear notches and easy-open systems

- Various seal patterns and shapes

- Static elimination

- Embossing

- Available with IQ/OQ construction

Viking Masek Rotary Premade Pouches

- Rotary premade pouch machines

- Increases output by as much as 50 percent

- Fill and seal premade custom pouches, eliminating the need for roll stock

- Single or dual lane automatic pouch packaging

- Includes six or eight stations

- Packages from coffee to snacks to legal cannabis products

- Volumetric, multi-head scale, auger, liquid pump, and cup fillers

- Infeed and outfeed conveying equipment

Rigid Containers

Denesters | Lid Applicators | Clamshell Container Sealing | Salad Tub

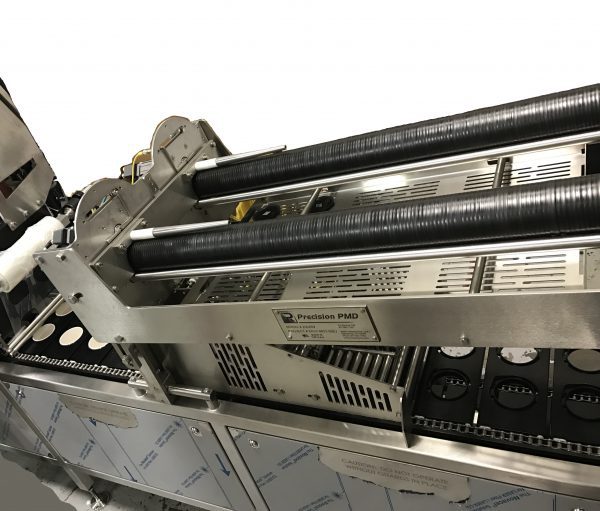

Precision PMD RC & PT Denesters

- Precision PMD Denesters place the cup/tub/tray/bowl onto a conveyor for filling

- RC SERIES DENESTERS are designed for Single Serve Cups to Foodservice Pans, Continuous to Intermittent Motion.

- Easily change container sizes without measuring and without acme thread adjustments

- Includes AB Servo & Controls

- Options: Portable Stand, PLC, Automatic Loader, Height Adjustable, Single or Multi-lane configurations, Change Parts for container sizes, Encoder, and Line Shaft Drive

- PT SERIES DENESTERS are designed for use with formed paperboard trays

- Continuous or Intermittent Motion

- Includes AB Servo Controls, Simplified Container Changeover, No Vacuum, High Speed

- Options: Same as RC Series

Precision PMD Lid Applicators

- Precision PMD Lid Applicators are an integral part of Denesting , Filling, and Sealing Systems

- Tamper Evident lidding

- Compact Servo Driven Applicator taking up minimal space for a fraction of standalone lid applicators sell for.

- Options: Servo Control, Automatic Loaders for multiple lid stacks, no container / no lid, standalone frame for mobility, single and multiple lanes,

- spinning rods

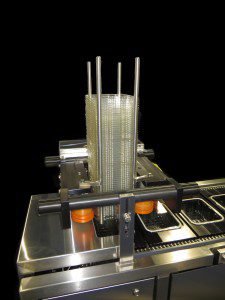

Precision PMD Clamshell

- Nuts, dried fruits and other snack mixes

- Bakery, Cookies, Popcorn, Seeds, pretzels and more

- Multiple Container Formats

- System displayed is Two Head VH Series Denester, Two Head Clamshell Closer, Integrated Net Weigh Filler (not shown), 50 containers per minute

Precision PMD Container Sealing

- Precision PMD designs and manufactures film membrane sealing systems for pre-formed and semi-rigid containers

- Sealers can seal paperboard, plastic trays, and cups

- Intermittent and continuous motion machines

- Frames, etc., constructed of Stainless Steel tubing, aluminum is hard coat anodized, and exceptional GMP

- 3 sealing parameters, all adjustable: Temperature, pressure, and dwell

- Sealing systems can cut the film between the containers or die-cut (perimeter cut) around the container

- Placement of pre-cut foil lids with no film waste

- Options: Film registration, Nitrogen Flush, Quick Change Seal and Die Cut Heads

Precision PMD Salad Tub

- Products packaged: Salad, Vegetables, Fruit Containers

- Retail and Club store Produce packaging to Single Serve Fruit Cups and Salad Bowls

- Options: Denesting, Product Filling and Tamping, Film Sealing and Die-Cutting, Lid Applicators, Scale Integration, 90* Tray Turners

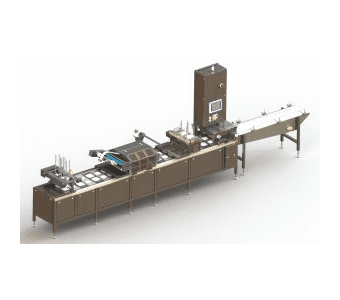

Precision PMD Complete Systems

- Precision PMD can provide complete lines for packaging of fresh, frozen, and dry products

- Starts with our Denester, then Filler, Sealing Section, and finally Lid Applicators

- Filling solutions include pumpable to dry and IQF items

- Fillers offered: Piston, Servo, Monorail traveling carriage, high-speed, Roto-Fill, Multi-Head Combination weighers

- Single to multi-lane application configurations

- Systems range in speed from 40 to 300 CPM (containers per minute

Product X-Ray Inspection

Mekitec

- Protect food safety and quality

- Inspect, detect, and reject hazardous foreign objects from production lines

- Record production and improve results based on inspections and traceability

- X-ray inspection technology inspects product density variations and is unaffected by metallic packages like cans or foiled films

The system can also inspect overall quality by analyzing the content of the packaged product, such as:

- Completeness and integrity

- Form and shape

- Presence and lack of presence

- Fill level

- Ensures all products are uniform in content, weight, and quality

- It can be integrated into either of Mekitec’s fully automated product quality control systems: MEKI or MIDMEKI

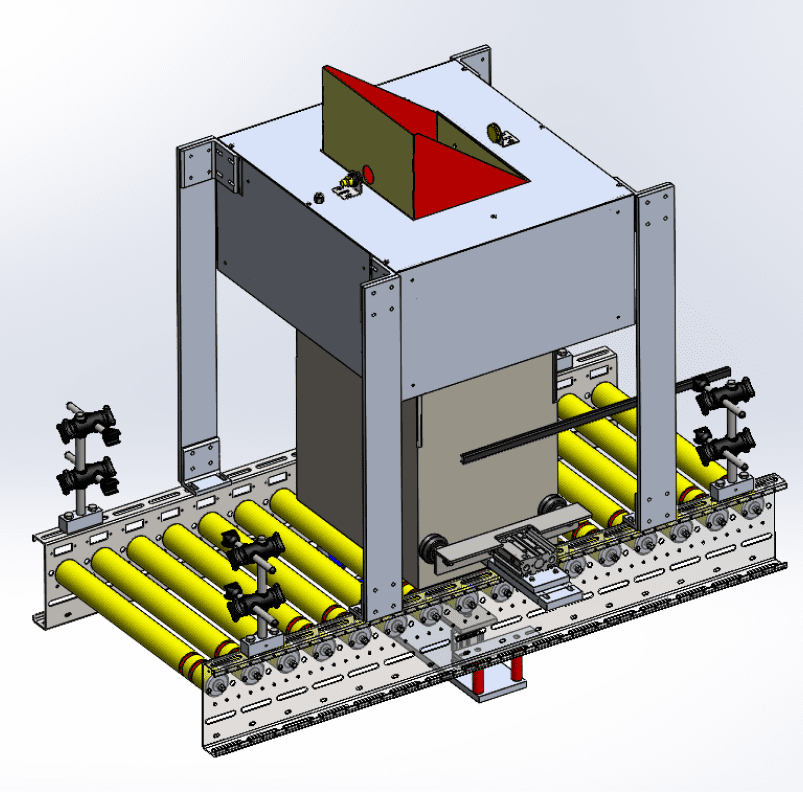

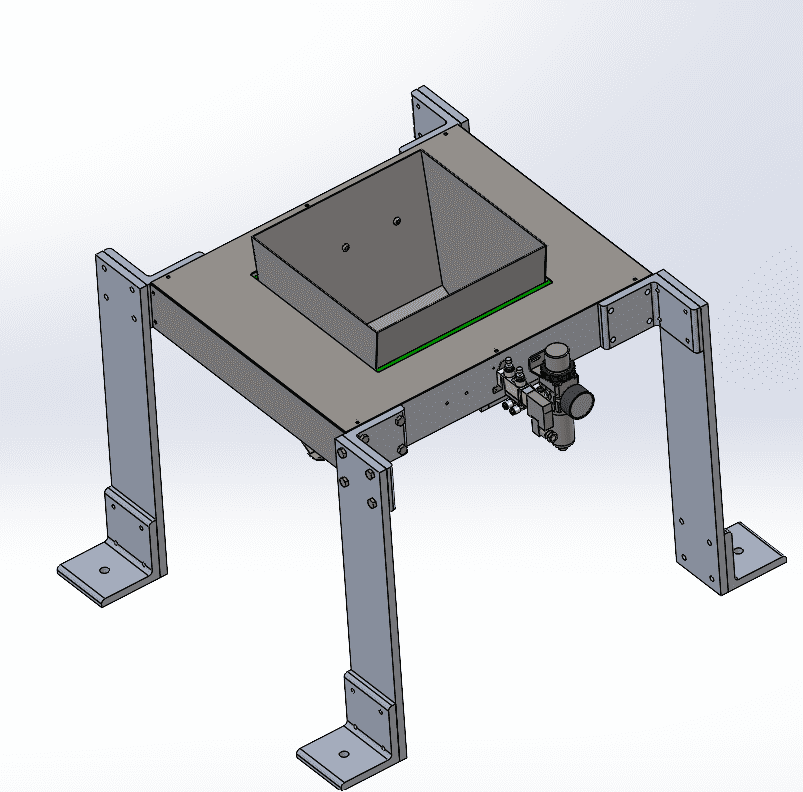

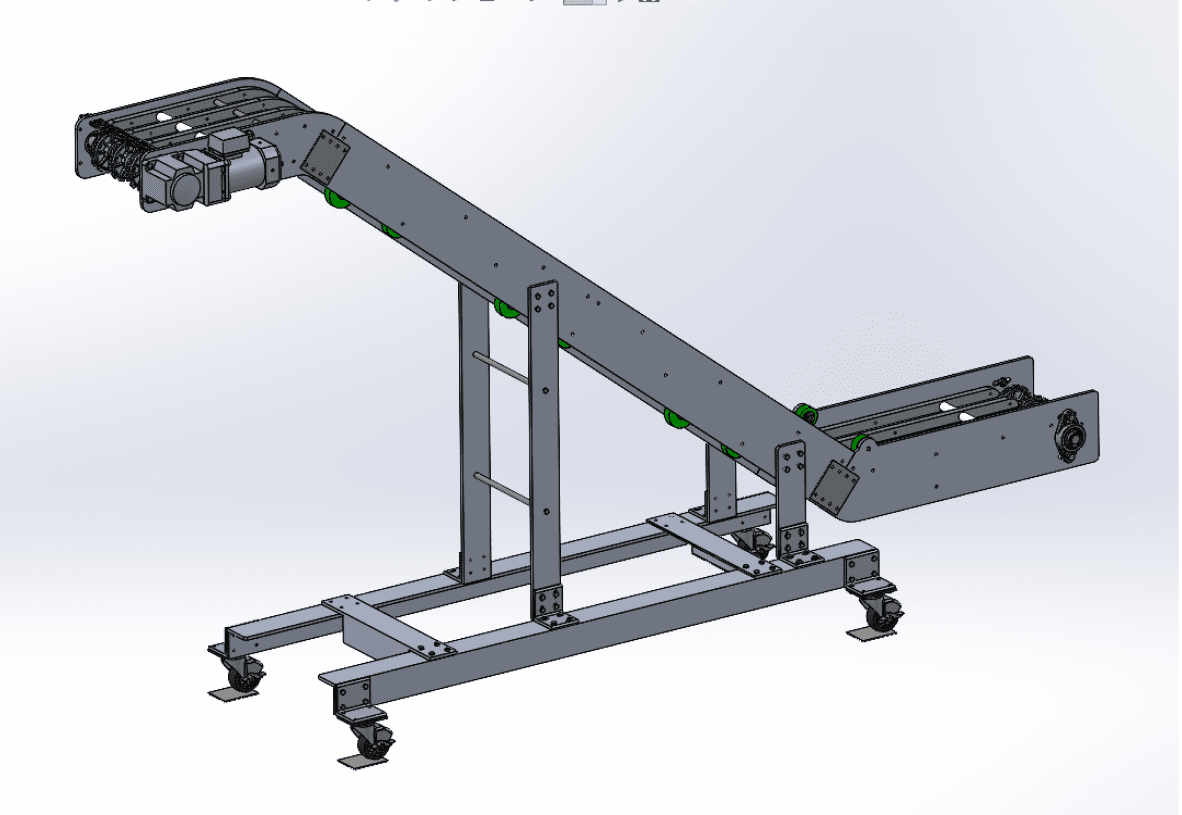

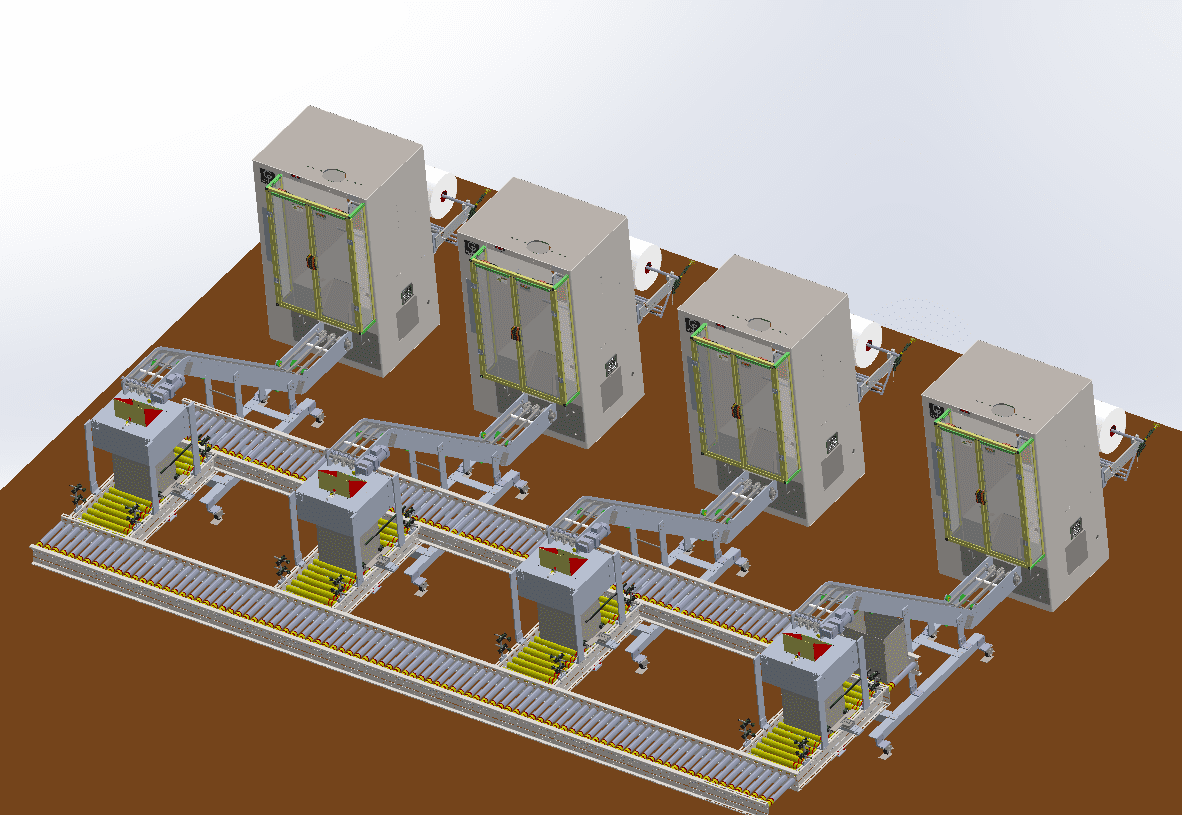

Batch Counting Systems

AS&E Integrated & Standalone

- Quickly and accurately batch product for end of line packaging

- Instead of pausing production, reducing throughput, we provide the necessary time to changeout boxes

- Engineered for bags and single serve cups, the bomb bay doors or star wheel design guarantees you get the exact amount in the box every time

- Can be mounted directly underneath sealing jaws, end of takeaway conveyor or integrated into new and existing conveying systems

- Conveyor, Batch Gate, Scale, Box Shaker (last image) is a standard model for frac bags/boxes of coffee. Two options available – NS or EW conveyors. Box Shaker and scale are integrated into the MDR conveyor section

- Multiple Component Configurations and Controls options to fit your current requirement and scalable growth needs.