Multilane Liquid

Filling Machines

Multilane Volumetric Liquid Filling Machine

Piston / Depositor Filler

Volumetric Technologies Multilane Liquid Filling Machine - Piston & Depositor

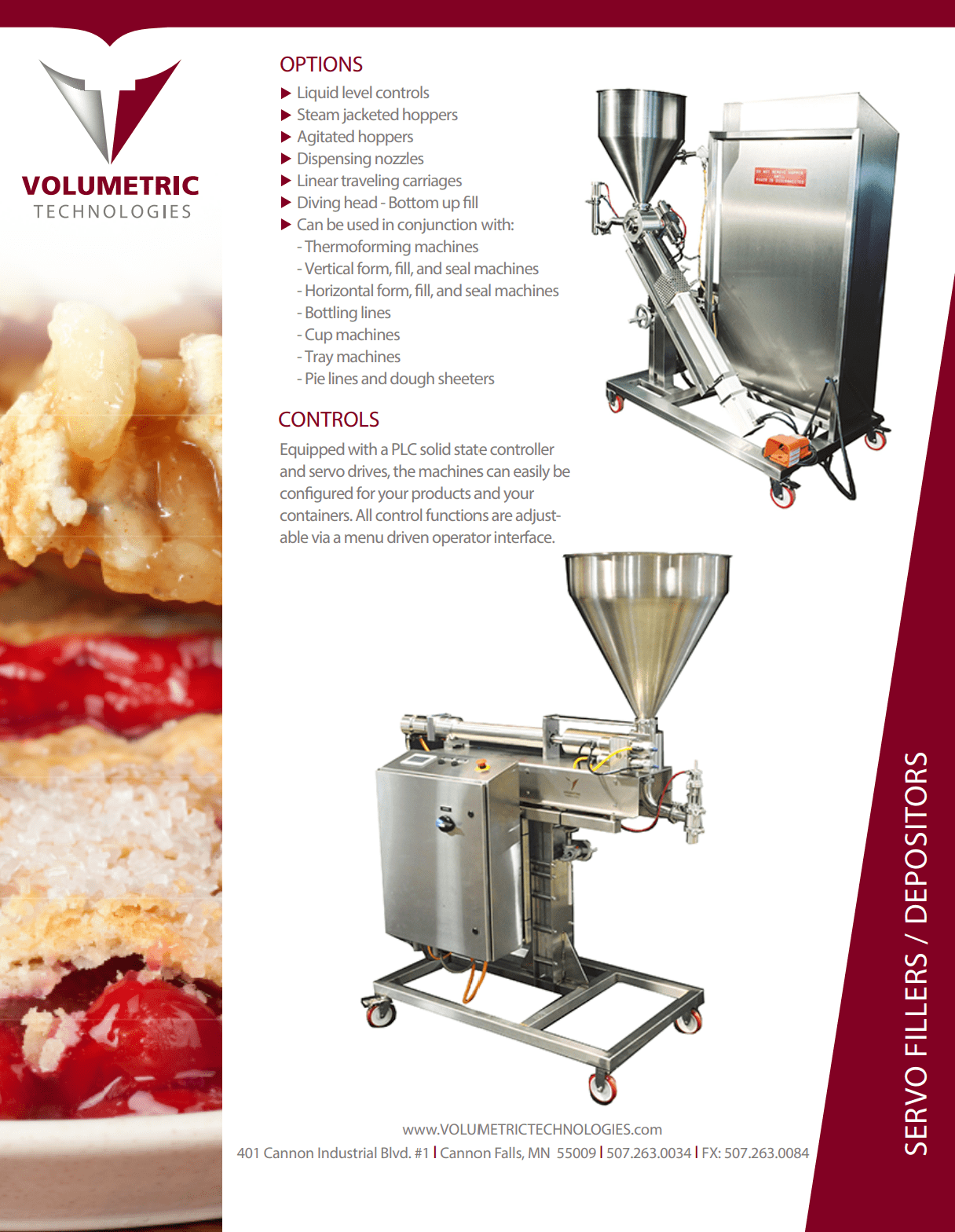

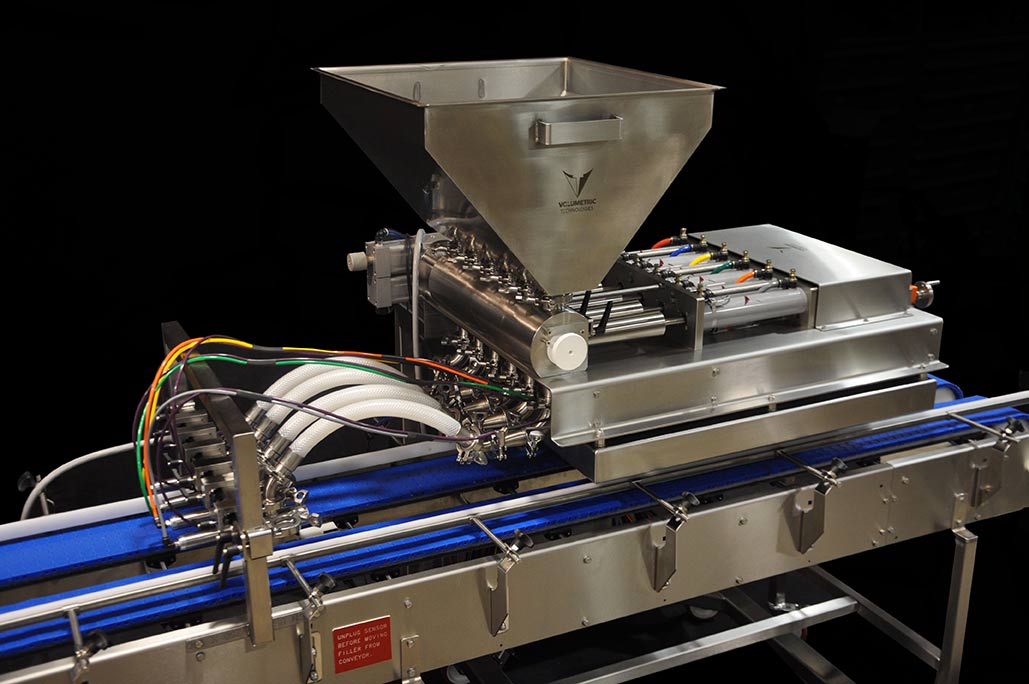

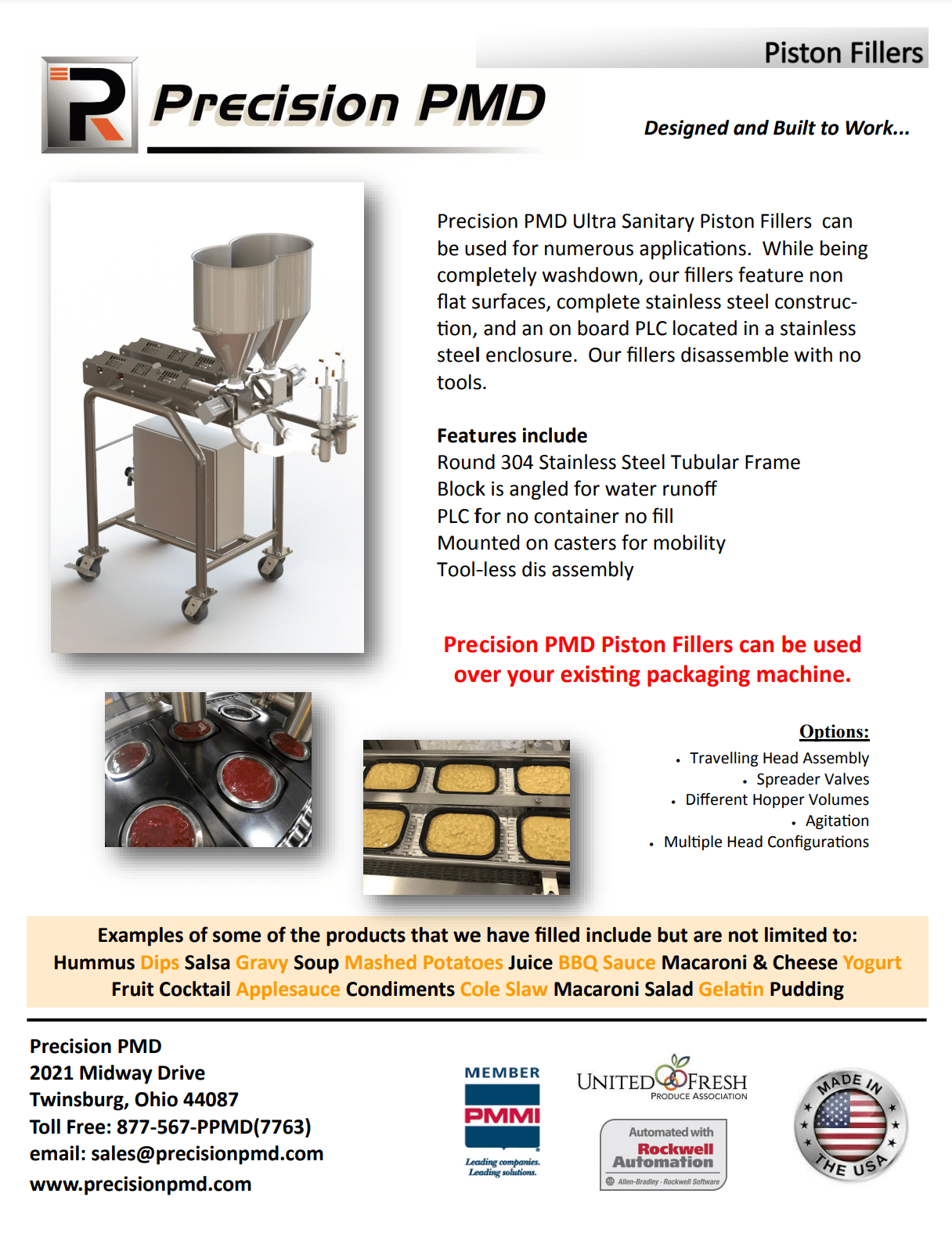

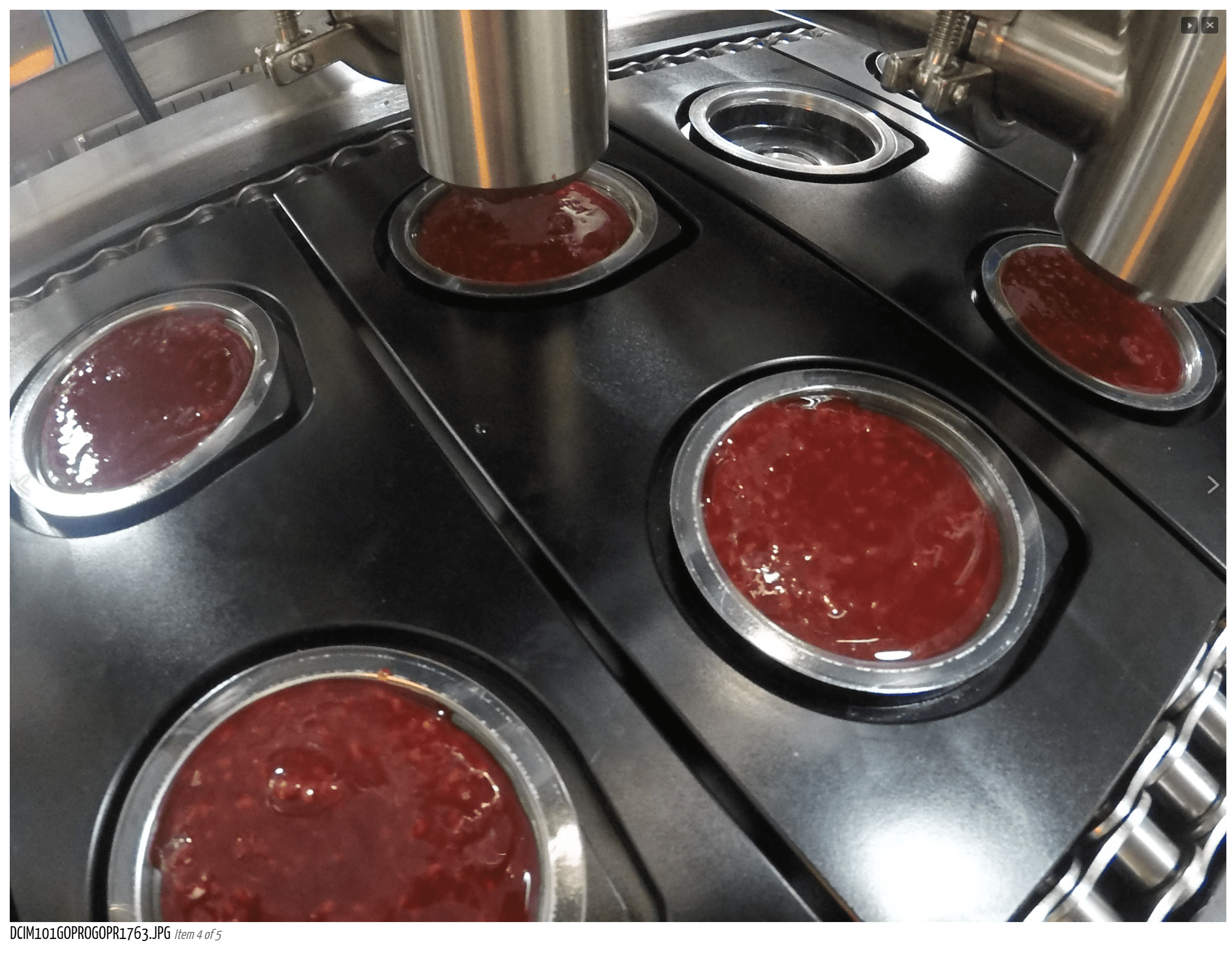

Volumetric Technologies Automatic Filling Lanes are used to automatically fill a variety of products into countless containers. Products range from barbeque sauce, marinades, soy sauce, pancake batter, muffin batter, jams and jellies, honey, dips and salsas, condiments, soups, peanut and nut butters, personal care products, industrial lubricants and adhesives just to name a few.

Maximize production with an automatic filling line as our innovative filling equipment is integrated with our conveying solutions to form a top of the line production machine. Our piston fillers / depositors combine innovative features to deliver the fastest speeds with the best fill accuracy and lowest level of product degradation. Equipped with a menu-driven touchscreen HMI and tool-free changeover, our automatic filling lines are easy and safe to operate.

Equip our piston fillers / depositors with our industry leading dispensing nozzles for the perfect solution to your applications needs. With over 100 standard and custom dispensing nozzles, we will have the best solution for your operation. Contact FES today to discuss your filling / depositing application to ensure you’re perfectly equipped now and into the future.

Servo / Piston / Lobe Pump

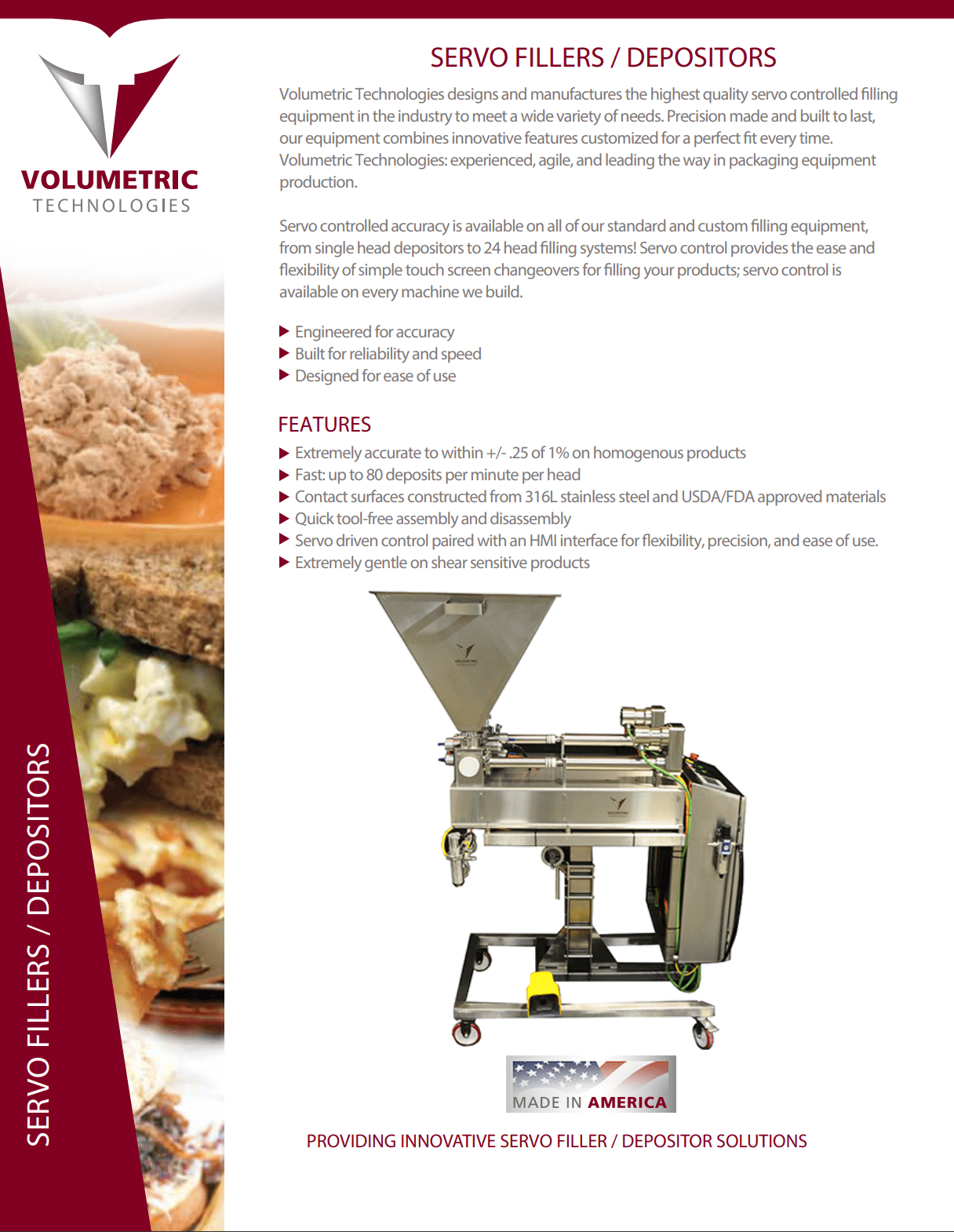

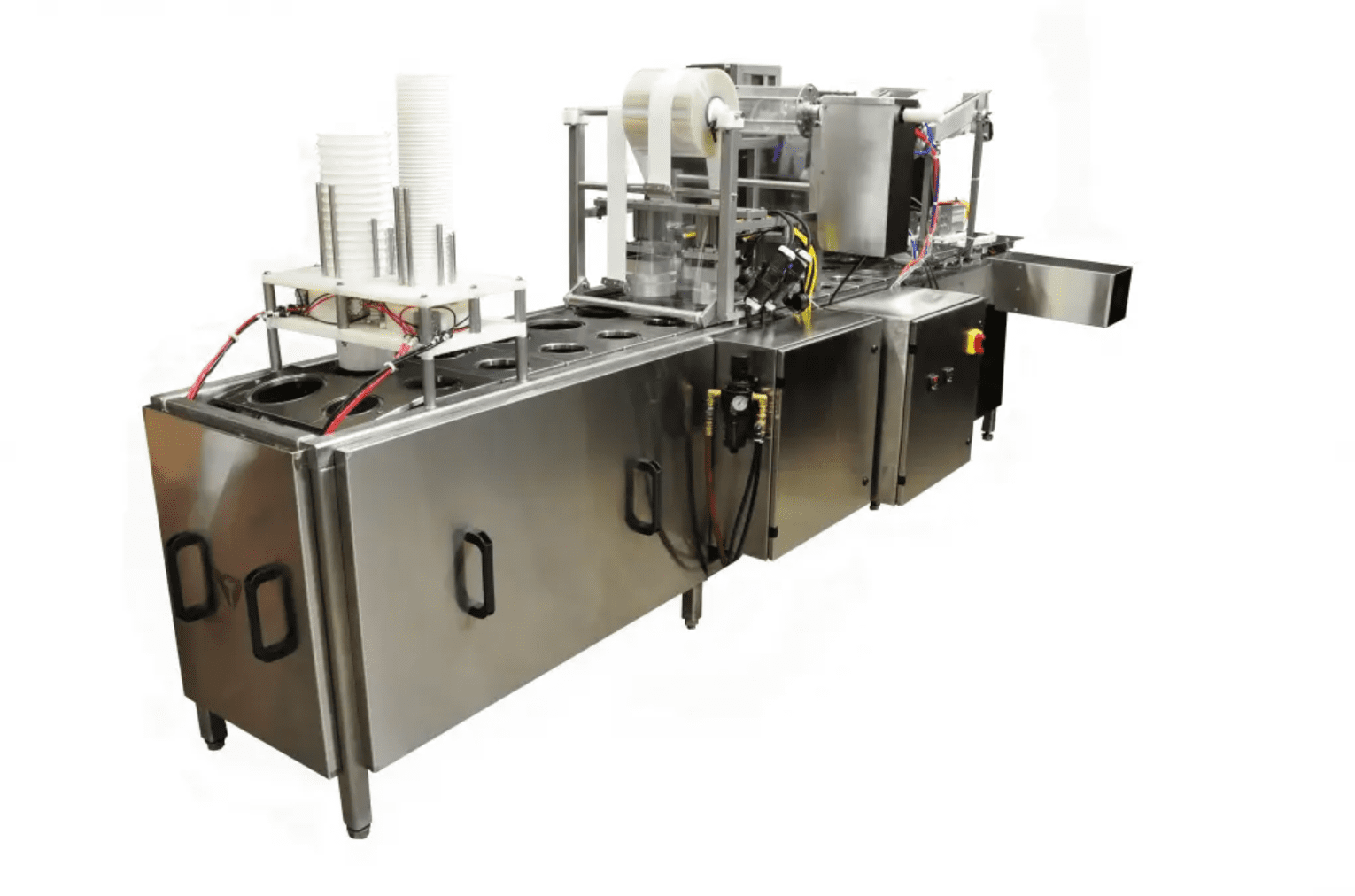

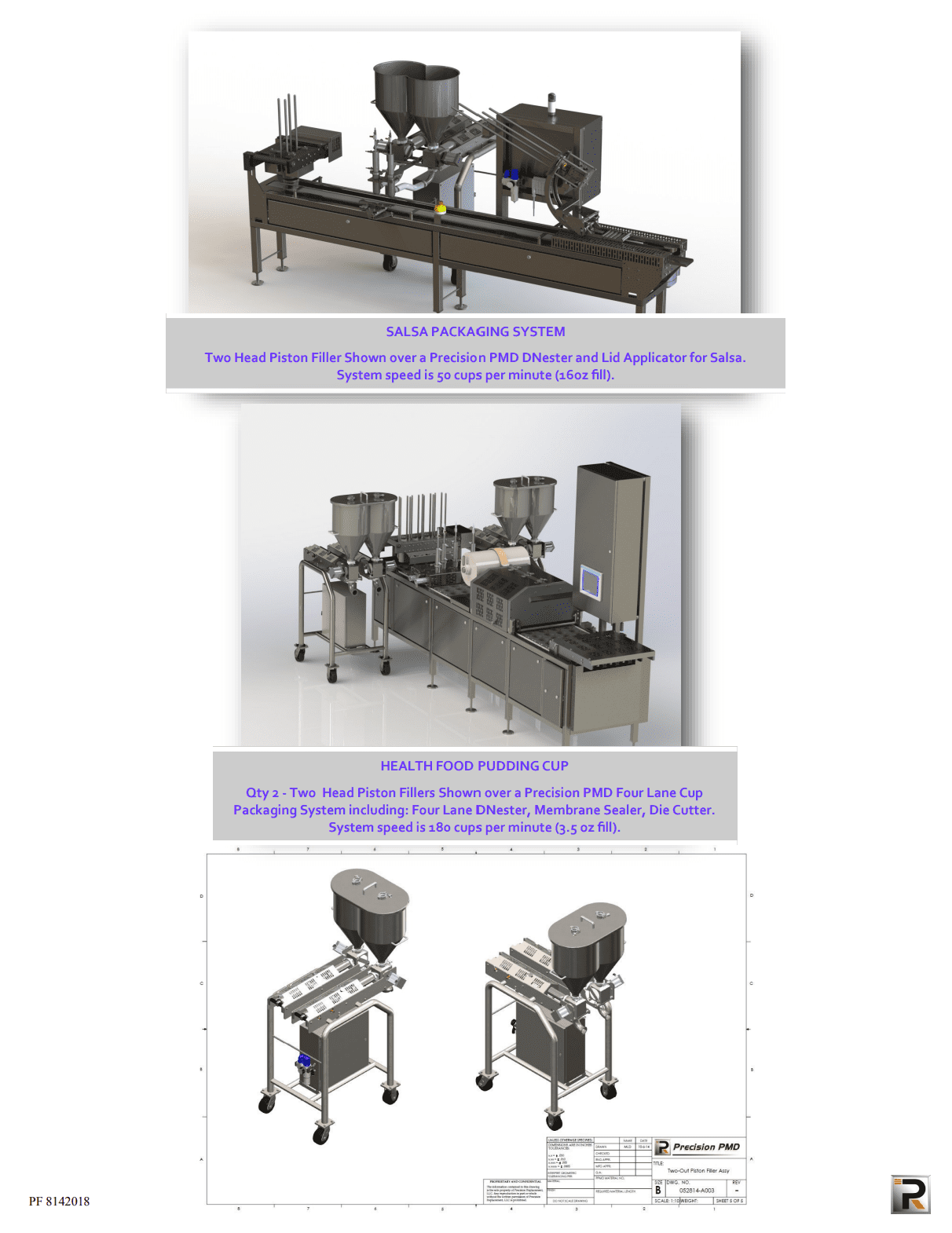

Precision PMD Multilane Liquid Filling Machine: Servo - Piston - Lobe Pumps

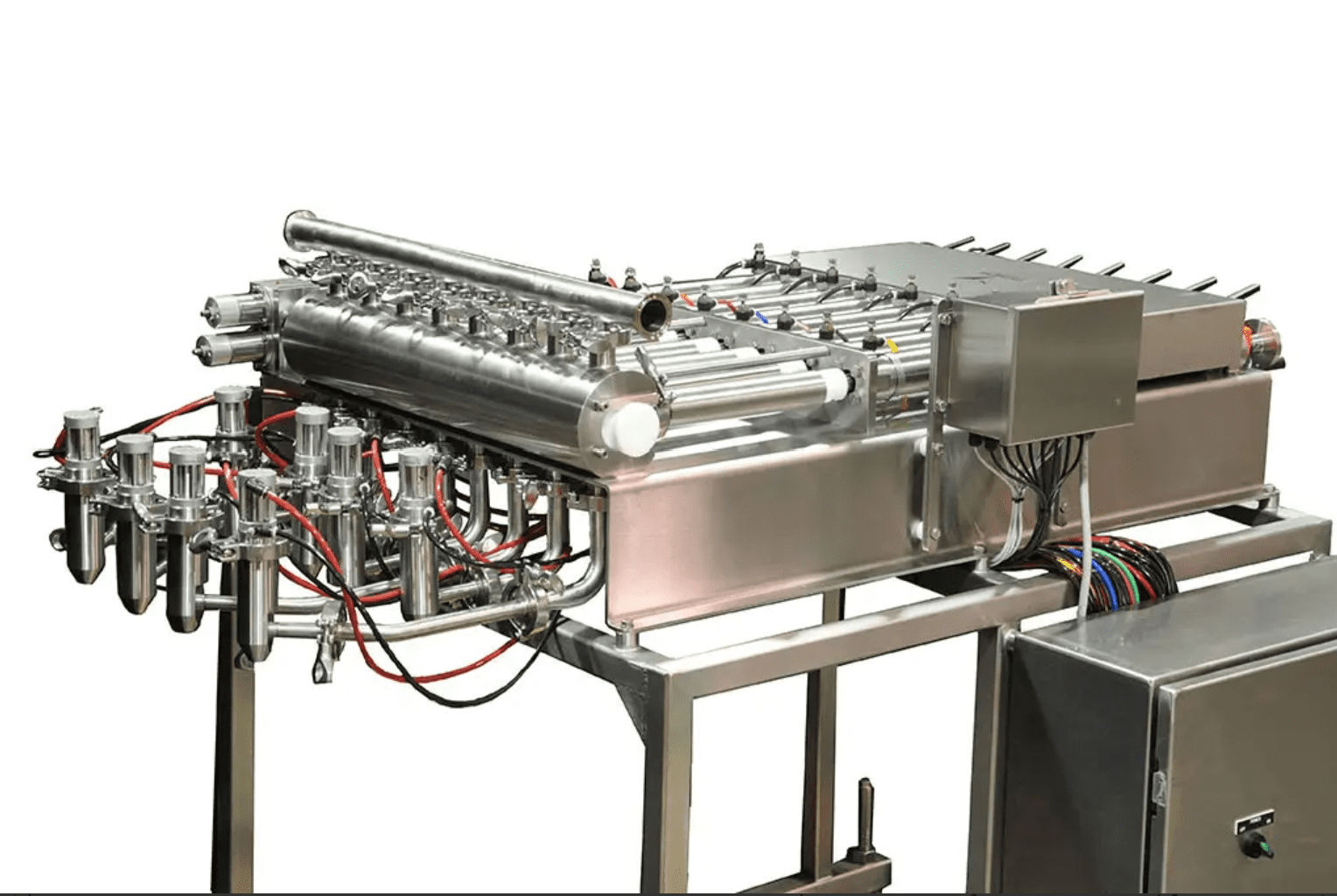

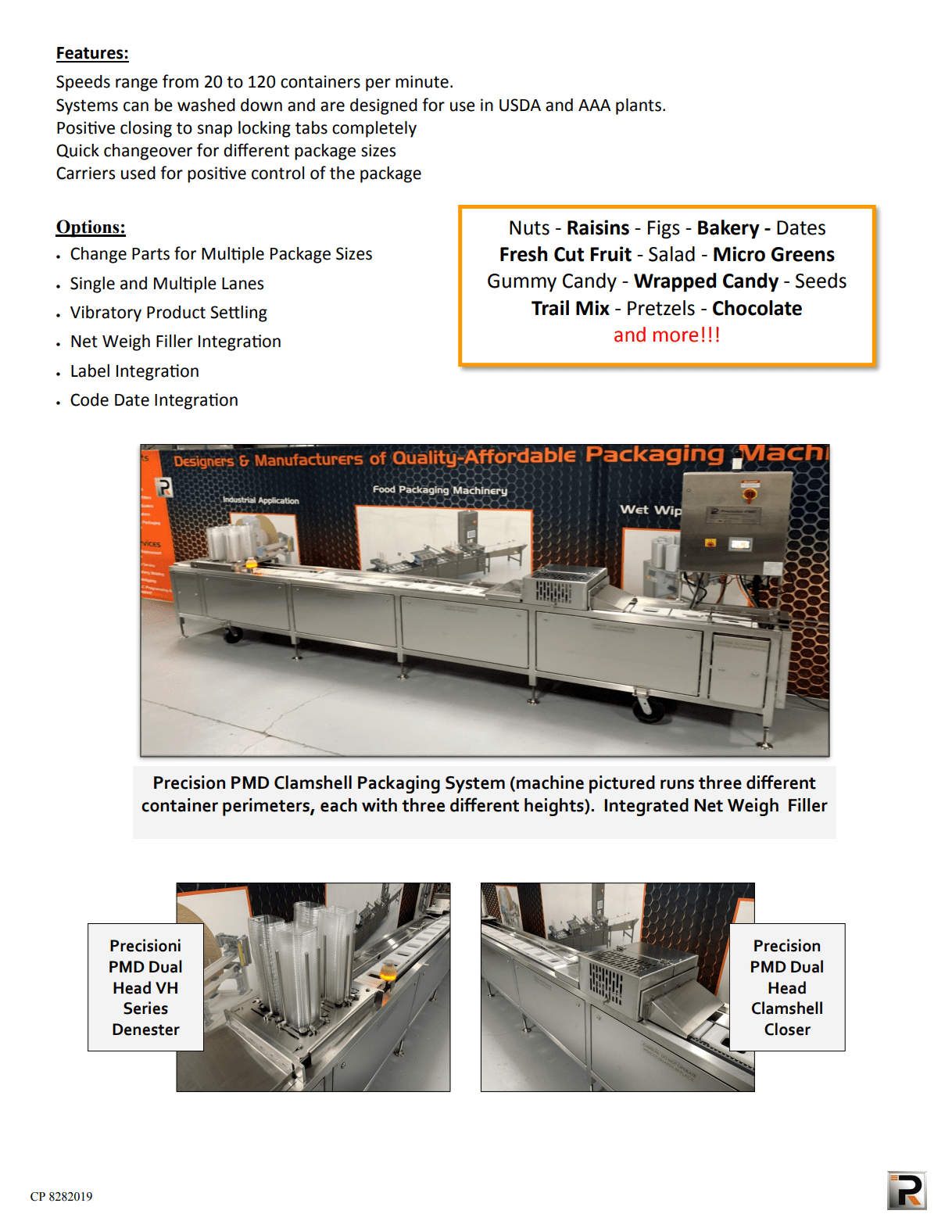

The PF Series Piston Fillers are capable of depositing range of products from as thin as water to as thick as mashed potatoes. They are designed to be Ultra-Sanitary servo, piston and lobe pump filling systems. Being completely washdown, our fillers feature non flat surfaces, complete stainless steel construction, and an on board PLC located in a stainless steel enclosure.

Features include: Your products are accurately and gently dispensed in any environment with no container – no fill controls. We provide round 304 stainless steel tubular frames where the block is angled for water run-off. Tool-less dis assembly and a mounted caster, portable design. Construction is 100% SS and FDA approved plastic. PLC controls for intuitive operator interface and simplified integration over your exiting packaging machinery lines.

Options include: A variety hopper configurations and with jacketed and agitation, multi-head net weight scale configuration, traveling head assembly, diving nozzles, spreader valves, level controls, servo controlled, checkweigher feedback.